If you’ve ever been to Hawaii, you’ve experienced its world-renowned beaches, friendly local flair and majestic landscapes.

But you’ve probably also experienced sitting in traffic for hours on end, specifically on the Island of Oahu.

Honolulu, the state’s capital and largest city, ranked as the 10th most congested city on a 2015 INRIX Traffic Scorecard. That benchmark report for the U.S. Department of Transportation also said Honolulu residents wasted 49 hours each per year sitting in traffic.

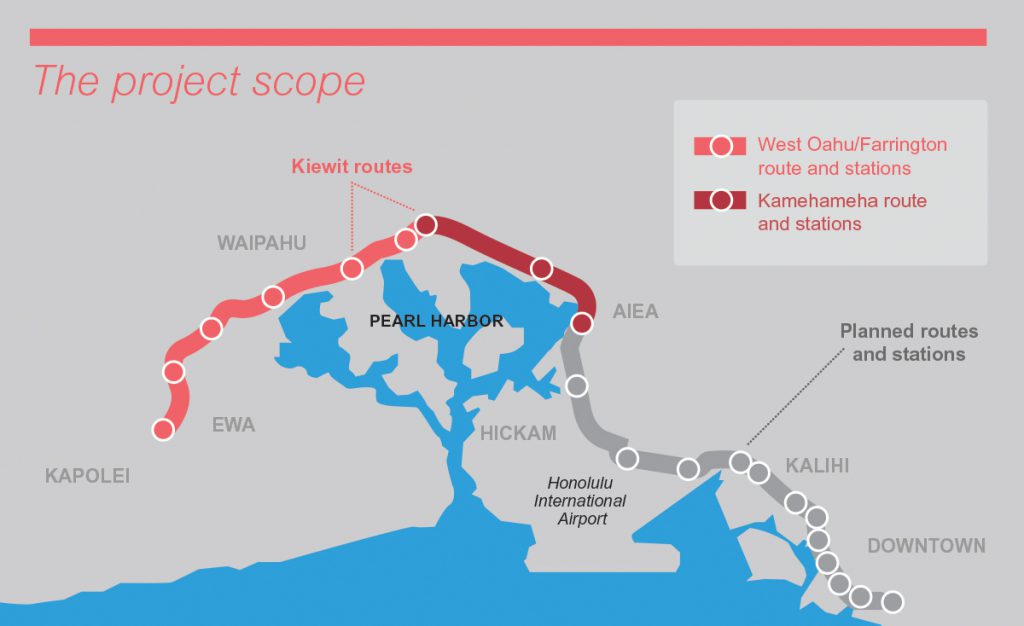

In an effort to help reduce congestion and improve the lives of its nearly one million residents, the City and County of Honolulu broke ground on Hawaii’s first light metro rail system in 2010. The 20-mile system will run from the community of Kapolei on the west side of Oahu through downtown Honolulu to the Ala Moana shopping center. It also will feature the country’s first automated rail system, with everything from free Wi-Fi to surfboard racks. The anticipated operation date for the entire rail line is 2025.

Kiewit was awarded the first three contracts for the rail system, which the newly established organization Honolulu Authority for Rapid Transportation (HART) is charged with managing, operating and maintaining. The scope of work includes the first 10 miles of elevated guideway as well as construction of the Rail Operations Center as part of the joint-venture team. Kiewit is scheduled to complete all of its rail-related construction in 2017.

Adapting and innovating

Kiewit is responsible for utility relocations, roadway restoration and all structural work and track installation for the elevated rail system. The team used a variety of unique construction methods to build the guideway through the highly congested areas of Farrington and Kamehameha Highways.

At the beginning of the project, the columns supporting the elevated guideway were built by placing the rebar first, then building the forms around it. After reviewing the process, the Kiewit team realized there was a more efficient way to build the 450 columns for the project: a form-first column method. This method uses the column form in lieu of external rebar bracing by installing the rebar cage after the form is set.

“The column group contributed to some of the company’s best ever unit rates in this type of work,” said Zach Reilly, Kiewit structures operation manager. “It also allowed the team to stay a step ahead of the segment installation team and make or beat our construction schedules.”

A first for the company was using the underslung guideway installation equipment, or truss, to install the more than 5,200 precast guideway segments on the project. Each guideway segment is like a puzzle piece and fits into a specific location; those segments are hauled to the site and picked from a crane on top of the guideway. The underslung trusses support the guideway segments from below while they are being installed, instead of from the top with an overhead truss.

“By documenting a step-by-step process for this approach, crews were trained and able to consistently perform the operation to meet quality standards,” said Kiewit Operations Manager Dustin Donahoo. “We needed to make sure we knew what all the steps were to the underslung truss and that we had good, solid processes that everyone could follow to prevent quality or safety mistakes.”

Using this method, crews were able to set guideway segments along the four miles of Kamehameha Highway, the second guideway contract, within a year.

The Honolulu rail project’s drilled shaft work was one of the largest self-performed efforts of that type in company history, at nearly 500 drilled shafts over 10 miles. Part of this work was the responsibility of Superintendent Eric Hermanson, whose crew faced Hawaii’s tough and unpredictable ground conditions, as well as tight work areas where drilling in narrow highway medians surrounded by traffic was the norm.

“There are so many things that are just not in your control, which makes scheduling work very hard,” said Hermanson. “The only way your team can be successful is if you adapt to change and never stop thinking outside the box.”

Project management recognized the group’s tenacity and commitment to delivering results.

“That group, more than any, had to battle the conditions day in and day out. Any time you’re digging into the ground there’s a chance you will run into something unexpected,” Donahoo said. “Successfully completing the drilled shafts was a significant accomplishment on this job.”

‘The lifeblood of the team’

Michael Fennerty has high expectations for himself and his crews. His grandfather, Frank, was the first recipient of the prestigious Peter Kiewit Award, given out every year to a company manager who best exemplifies Peter Kiewit’s commitment to excellence in all aspects of project or mine management. Fennerty’s goal is to hopefully match his grandfather’s success with the company, and he’s learned enough in his first few years to lead him in that direction.

“Communicating internally is really important to set you up for success,” said Fennerty. “You also have to get to know your crews on a personal level to build team trust.”

Fennerty is part of a group of young leaders on the project management team entrusted to run a variety of operations, from setting the guideway segments to leading complicated utility relocations.

“In the summer of 2015, we made a commitment to take on young engineers on the project, and we gave them opportunities to be productive members of the team,” said Kiewit Project Principal Phil Wallace. “They have learned and grown in their careers and faced every challenge head on. We would not be where we are today without their contributions.”

These younger, talented rail project team members are contributing to the project in a variety of ways. For example, Fennerty’s crew worked on the future Leeward Community College station structures and was able to make schedule and record no safety incidents or quality issues — all while beating budget.

Mitch Chicha started as an intern with Kiewit and has been a full-time employee now for six years. In July 2015, his crew was tasked with setting up the third truss system on the project. He and his crew were able to set two miles of guideway segments in just over a year with a great safety record and production units.

“Our success was not without challenges, but with the right guidance and collaboration, we were able to finish strong and share an amazing experience,” Chicha said. He said he’ll continue to benefit from that experience as his career progresses.

“Diving into the operations in Hawaii head first with an optimistic attitude and an open mind was the best career move I could have ever made,” said Chicha. “I have been able to put an entire new skill set under my belt that will be extremely valuable for future work.”

“The younger members of this team are the lifeblood of the team itself,” said TJ Paul, Kiewit deputy project director. “Watching them take on challenge after challenge and observing their professional growth during that time is one of the most fulfilling aspects of managing work.”

Taking on challenges, thinking outside the box and working together as one team have ultimately led to the rail project team’s success.

Kiewit laid 224,000 linear feet of rail and built various crossovers along the alignment, including at the future Pearlridge station.

Crews were responsible for building the Leeward Community College station structures, which included grading, walls and utility work.

Working together

Between the levels of expertise and experience on the Honolulu rail projects, every Kiewit employee had one goal — to work together as a team and provide a safe and quality system to Oahu’s residents.

“A large portion of our team’s success was due to embracing a team mentality,” said Brent Scheele, Kiewit project manager. “Many people accepted new roles and will benefit from their experience here when constructing future projects.”

It also meant working together and shifting resources to meet an aggressive project schedule and improve field operations.

“When one area of the project had challenges, the team was quick to lend a hand and send reinforcements,” said Reilly. “We put the long-term success of the project ahead of our individual groups. This unity allowed the team to overcome even the toughest obstacles.”

Unity on the project spread beyond the jobsite. Kiewit partnered with local schools to provide science, technology, engineering and math (STEM) exercises and presentations, donated to local charities through the Safety Crew of the Month program, and worked to address residential and business concerns during construction. Building all of this goodwill and camaraderie brought a sense of pride to the team working on Hawaii’s largest public transportation project to date.

“This is hands down the coolest job I’ve ever been on,” said Donahoo. “This is definitely an iconic project in Hawaii — something that will be here for years. No matter how many decades later, we’ll see it and know that we built it.”