Meet the experienced team that’s putting projects on the fast track to success.

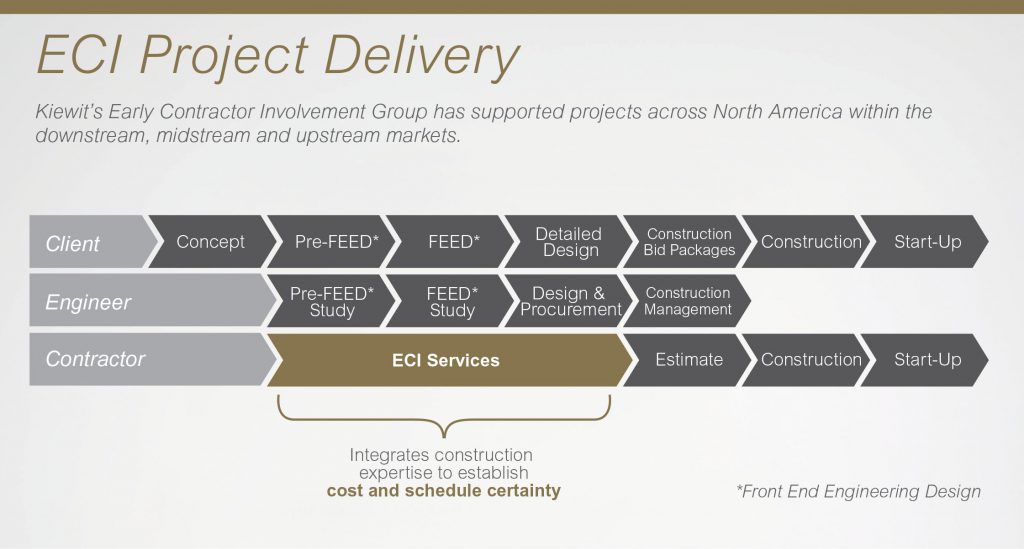

They say hindsight is 20/20, but when it comes to construction, those front-end blind spots can be extremely costly. Often, the first seeds of trouble are inadvertently planted during the pre-FEED and FEED (Front-End Engineering Design) stages of a job. But an innovative project delivery method being implemented by Kiewit is bringing those blind spots into focus. It’s called Early Contractor Involvement, or ECI, and it is successfully preventing potentially costly surprises late in the game.

“In the traditional approach to project execution, the construction contractor is typically not brought into the project until the FEED stage is completed,” explained Jeff Gordon, vice president of Kiewit Energy Group based in Houston, Texas. “In recent years, however, many of our oil, gas and chemical clients have moved toward bringing contractors in early to validate estimates, and to build realistic and dependable schedules. Clients are getting constructability input early from the people who are building the work,” said Gordon.

Delayed schedules, unrealistic cost estimates, and last minute changes in execution strategies are familiar roadblocks across the industry; however, Kiewit leaders discovered that this movement toward early involvement is getting big results.

“We found that when our teams got involved earlier, the projects they were building had the best contract models and the best risk profiles,” said Brad Kaufman, senior vice president at Kiewit Energy Group.

Building the a-team

In the summer of 2013, Kiewit began efforts to formalize its ECI offering in the oil, gas and petrochemical markets. Kiewit swept the company for its most knowledgeable builders and assembled what Kaufman calls “a dedicated A-team.” It’s made up of about 40 people with hands-on experience executing successful projects of all types and sizes. Additional staff from across the company are brought into ECI projects as needed, matching the right experts to the right projects.

“We set up this group of key subject matter experts in a variety of disciplines to focus on ECI and develop the framework of what a standard ECI model might look like. Then we presented it to our managers,” explained Kaufman. “It’s not surprising that they all bought in right away.”

Clients and the engineers designing those projects also saw immediate value.

“I call it ‘three legs of the stool,’” said Kaufman. “Allowing the experienced people who have built similar projects to get involved in early strategic decisions allows the entire team to be successful — the contractor, engineers and clients,” he said.

Kiewit’s ECI team uses relevant construction know-how to identify cost- and schedule-saving opportunities that might otherwise get overlooked by designers in the early stages. That leads to transparent and realistic estimates, plus it optimizes project controls, which are the data gathering, management and analytical processes that come with every project.

“To add value to the project, ECI really needs to have three elements,” said Kaufman. “It has to have the right contract risk model; it has to provide schedule and cost certainty; and it has to further our long-term relationships with our best clients. By getting into the early stages of the project development cycle, we can achieve all three,” he said.

“It also provides built-in access to Kiewit’s direct-hire labor experience,” adds Gordon. “It’s the perfect opportunity for clients to leverage our extensive craft relationships and develop reliable labor execution plans,” he said.

Construction-drive results

One of the first projects to leverage ECI was Imperial Oil Limited’s (IOL’s) Kearl Oil Sands project in Alberta, Canada.

“We dedicated a team of builders to work with AMEC, the engineering design firm, on the early stages of Imperial Oil’s project,” explained Kaufman. “IOL appreciated the input that they just couldn’t get from designers, and that project was highly successful for everyone,” he said.

Ken Choyce, project manager in engineering and construction at Summit Midstream based out of Houston, is another satisfied customer.

“I remember the initial meeting when Kiewit was promoting the concept,” said Choyce. “When our grassroots compressor station project came up in Colorado, it seemed like a natural fit.”

Kiewit’s ECI team started interfacing with the engineers on the project and assessing plans. Choyce said having the ability to see the project from a construction perspective helped prevent unrealistic expectations.

“I was really impressed with the focus Kiewit’s ECI team brought,” recalled Choyce. “What was promised was exactly what was given. It was done on time and communication throughout the whole process was excellent and very transparent.”

After ECI’s initial economic analysis, the Summit Midstream team found itself in a better position to make informed decisions about the project’s future.

“We realized that, commercially, following through with the project wasn’t going to generate the rate of return we needed, and we turned to other alternatives,” said Choyce.

The experience left a lasting impression on Summit Midstream.

“As far as I’m concerned, if something of this magnitude comes along again, I’m going to take this approach. I’ll definitely re-engage with the Kiewit team the first opportunity I have,” he added.

Shining a light on the blind spots

Mike Allen is director of projects for Wood Group Mustang — an engineering and project management company that reached out to Kiewit’s ECI team for help during the estimating phase of a major refinery revamp project.

“We were looking for people to help us with constructability,” said Allen. “It was a pretty complex job and Kiewit helped us lay out everything in an organized fashion to fine-tune the estimate for better accuracy. The team really knew what they were looking for,” he said.

Allen echoed Choyce’s experience, stating, “If we can find an opportunity to partner up on a large job, we’ll definitely do it again.”

Eating our own cooking

Kaufman admits that this new model isn’t only about protecting the client, it’s about optimizing construction execution performance as well.

“We have a term within our ECI group that we like to use. We call it, ‘Eating our own cooking,’” he said. “Nobody likes to get involved in a project after it’s been fully planned and then be told how to execute the project. Time after time, we’ve seen challenges in the execution stages that could have been identified and solved during planning if constructability input had been incorporated early. Bringing the construction team in early allows us to be involved in planning and therefore we don’t have anyone to blame down the road.” said Kaufman.

And the feedback Kaufman is getting from internal and external partners reinforces his belief that ECI is changing the industry for everyone involved.

“I don’t think a week goes by where we don’t get two or three calls about our ECI services,” said Kaufman. “Some are from clients, and a lot are from engineering partners that we’re currently working with on other projects. They see the value we bring and they’re asking us to participate on additional projects early. That tells me we’re providing a service that is lacking in this industry,” he said. “Ultimately, ECI is about facilitating a collaborative, transparent, ‘One Team’ approach and driving the best project results.”