Kiewit is in a new era — one where construction meets technology. And it’s a match that was long overdue.

While other industries were making huge strides in increasing productivity with technology, the construction industry was showing little interest. Kiewit was no exception. The company was wildly successful but projects were getting bigger and more complex. They relied heavily on paper, spreadsheets and decisions based on gut instinct and the last month’s numbers.

It all changed in 2009 when Chairman and CEO Bruce Grewcock visited the site of a billion-dollar project. He saw a 1,500-page, double-sided cost report sitting on the project manager’s desk and decided then and there that there had to be a better way. Shortly thereafter, the technology transformation began.

Grewcock asked Kiewit’s senior leaders to assign some of the best operations people they had to the technology initiative. He knew from the start that any technology, either bought or built, would be successful only if it could improve on how Kiewit builds work using its proven fundamentals.

Kiewit started by identifying the best estimating and enterprise resources planning (ERP) systems available. It started as a technology initiative and quickly morphed into something much larger, with standard cost codes, consistent tools and common processes used across the business, said Project Director Tom Howell, now sponsoring various mega-projects for Kiewit Infrastructure Co.

Jake Macholtz worked with Howell almost from the beginning of the project. He now leads all corporate technology initiatives as vice president of Kiewit Technology.

“Our approach was to design what we needed, buy solutions that would meet our needs and build what wasn’t commercially available,” Macholtz said. “We kicked off the project in 2010 and five years later, we were running on the most advanced technology available — technology designed by and for the construction industry.”

The technology continued to evolve with new applications that put electronic devices and productivity apps into the hands of employees out in the field. Kiewit developed apps to electronically share daily plans, inspect equipment and capture quantities and man-hours.

The system has since grown to include systems and tools to manage every part of Kiewit’s business and the entire lifecycle of a project.

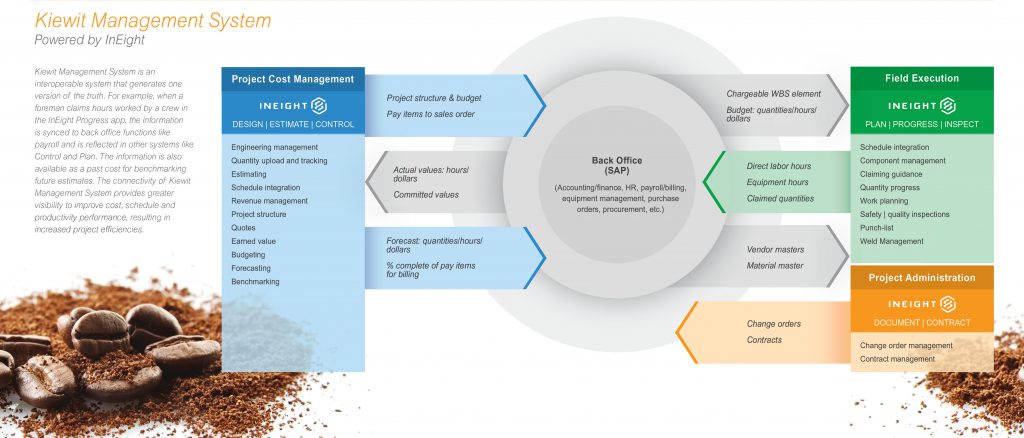

It’s called the Kiewit Management System (KMS) and it’s made up of a combination of third-party and home-grown applications. What makes KMS so special is that everything is integrated, from the estimate to project cost management, procurement, field execution and administration.

The transformation wasn’t easy but it was worth it, according to Project Director Eric Thoendel, who was with the technology initiative from the beginning.

“In just a few years, we successfully transformed the company from spreadsheets and paper-based processes into a streamlined electronic capture and delivery machine capable of serving up the real-time data needed to make faster, better decisions,” he said.

John Jennings, president of Kiewit Power Constructors Co., agreed, adding that in addition to the savings realized with the elimination of paper timecards, requisitions and documentation, Kiewit projects now have real-time access to data to help manage operations.

It’s led to better reporting, said Jennings, and with better reporting, clients have more confidence that Kiewit can:

- Accurately know the status of projects

- Identify issues earlier

- Leverage lessons learned across Kiewit for the benefit of the project

- Improve processes as problems are solved

“We are doing collaborative information sharing with our clients, including design models, document transmittals, issue identification and tracking,” Jennings said. “On EPC (engineer, procure, construct) projects, this has allowed us to shorten our design schedules.”

Kiewit is also using technology to capture the education, experience, training and qualifications of staff. Having this information electronically available helps managers plan staff recruiting and career development and to fill roles on upcoming projects.

Technology solutions at Kiewit are all fully integrated, providing unprecedented access across the organization. That translates into an improved ability to consistently deliver projects on time and on budget.

Proven results

Kiewit project teams are now spending less time creating daily plans, claiming quantities and filling out reports and more time in the field where they are needed most. Management is spending less time crunching numbers and analyzing reams of outdated information.

The estimating process is more efficient and accurate, leaving estimators more time to think about schemes than ever before.

“With quantity tracking, our ability to know where we’re at on a project is leaps and bounds better,” said Macholtz. “Our data gives us the ability to recognize projects in trouble earlier and do something about it before it results in job losses.”

Consistency across all projects is another win. “We’re all managing to the same account codes, which we didn’t do in the past,” Howell said. “It’s more visible, more transparent to everyone what’s happening on projects because of this one product, one approach from top to bottom.”

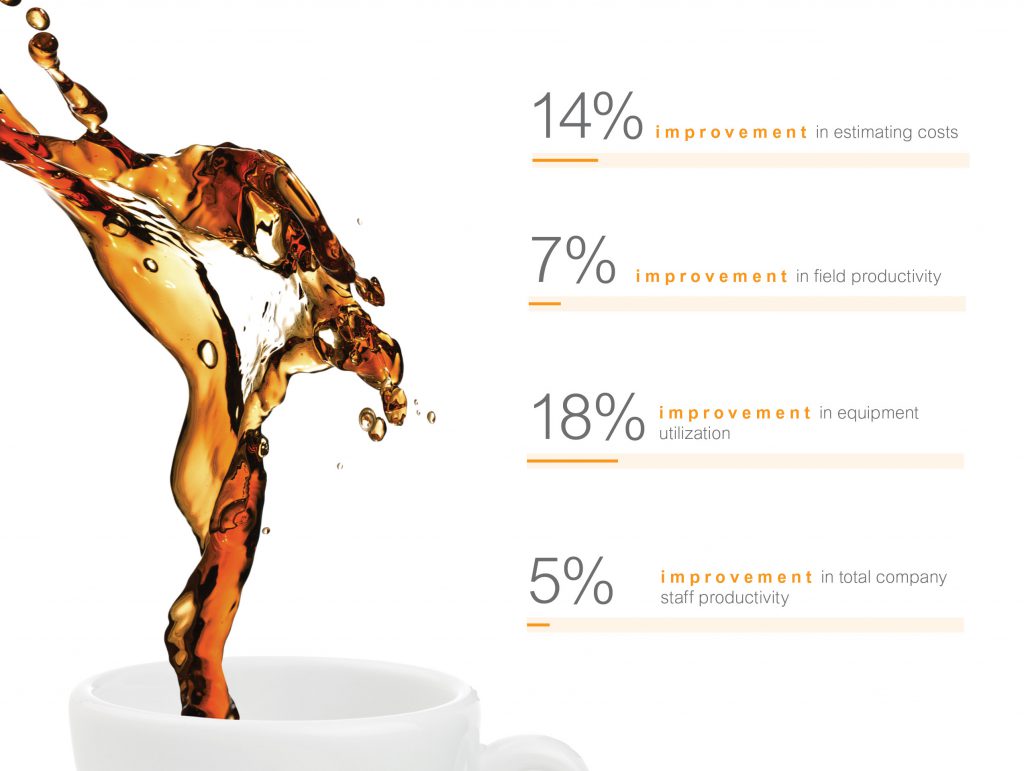

Kiewit is still in the process of implementing the latest technology on all projects but is already seeing dramatic results, as shown below.

“Technology used to be viewed as a cost to be minimized, but now it’s seen as an investment in our future, no different than our equipment fleet is an investment in our ability to build work,” said Macholtz. “This is a wholesale mind shift.”

What’s next

Kiewit is bringing these powerful, proven technologies to the construction industry through its InEight subsidiary. InEight is a commercial software company with more than 25,000 active users in 750 companies.

InEight is charged with continuously improving the software and works closely with Kiewit and other construction industry leaders to identify new solutions and improve on the existing technology.

“We have powerful, proven project management software that eliminates the guesswork in construction, providing real-time information and insights needed to minimize risks, improve operational efficiency, control project costs and collaborate with stakeholders,” said Macholtz. “It’s been transformational in helping Kiewit and other InEight clients deliver projects on time and on budget.”