Drones have long been a presence on Kiewit jobsites, taking aerial photos and videos. But it’s more recently that they’re playing a part in keeping crews safe.

On the Southeast Connector Project for the Texas Department of Transportation (TxDOT), Kiewit is using drone footage to observe employee behaviors, how they interact with equipment on the job and overall operational efficiency.

Located between Fort Worth and Arlington, Texas, the Southeast Connector is a design-build project performed by a joint venture with Kiewit Infrastructure South Co. and Austin Bridge & Road, aimed at rebuilding and widening crucial roadways. The project encompasses 16 miles of I-20, I-820 and US 287, as well as the reconstruction of three major interchanges. At peak construction, the project will involve 220 staff members and 800 craft workers, including subcontractors.

Reviewing the data

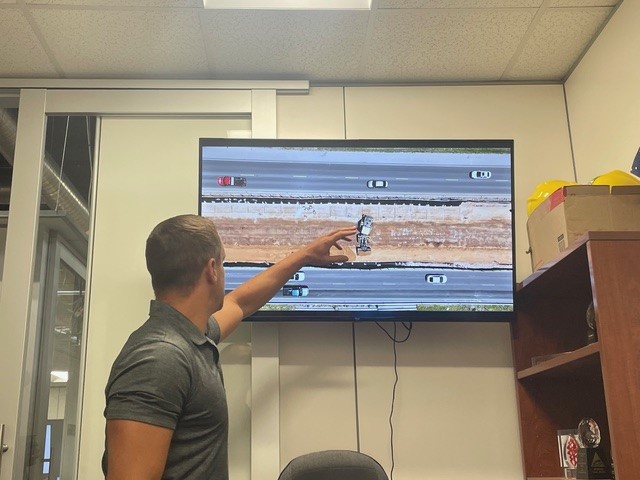

Kiewit’s drone pilots, licensed by the Federal Aviation Administration (FAA), fly drones approximately 100 feet above the jobsite, capturing live video and generating thousands of still images per minute.

Project Safety Director John Cloutier reviews the images and takes notes. Other members of the team, including the general superintendents and field superintendents, then review a summary with the crew.

Cloutier likens it to a coach sharing the previous week’s game footage with players.

“We watch it together and the superintendent goes out with the crew and walks through the screenshot photos, saying, ‘This is a good example of spotting around the power line. This is an example of how we don’t want to do that, and here’s what we need to do differently,’” he said.

A real-time perspective

The use of drones provides a unique vantage point, allowing the team to assess safety practices and construction progress from above. According to TxDOT Project Manager Prapti Sharma, the ability to review real-time data has been invaluable.

“The real-time data has helped us verify the progress of the project as well as have a bird’s-eye view of the project,” she said. “This also allows the TxDOT team to show the progress of the project to the district office as well as the project partners.”

It’s important to the Kiewit team that the drone perspective offers a look at the entire operation and helps identify where to improve safety, Cloutier said.

“We really look for two big things,” he said. “First, where our people are standing and walking, and whether there is something we’re missing in how they interact with equipment and trucks moving through the site. Second, how well is public traffic separated from our operations? Do we have the right lane closures in place? Do we have the right protection or teammates in place to protect our people the best we can from being struck by a third-party vehicle?”

The drone’s 100-foot bird’s-eye view of the project provides an ideal vantage point for spotting potential safety issues and tracking project progress.

A drone operator controls the aircraft from the ground, capturing video and generating thousands of still images per minute.

Creating jobsite solutions

Giving crews a buffer between them and road traffic is crucial. Drone footage has been instrumental in giving the team a unique view of where people are standing in relationship to the traffic, said Will White, project director.

“It allows us to change our lane closures to give the guys on the ground more room so that they don’t have to be directly adjacent to the traffic,” he said. “When you’re standing on the ground looking at it, you see that, but you don’t get the perspective that ‘Hey, traffic’s whipping by at 35 or 50 miles an hour and this guy is literally five feet away from the car when he’s in this position.’”

Sometimes, the solution is as simple as giving crews more space. Where crews were pouring concrete, the team pushed out the boundaries of the closure and set a traffic control truck with an arrow on the back to protect crews, as well as a crash cushion to protect the driver.

In another instance, drone footage revealed where safety protocols could be improved to keep equipment a safe distance from the crew and from traffic.

As crews were building a temporary 30-foot-tall wire-reinforced wall, they used compactors to tamp down material. Eventually, the operation placed workers directly above live traffic.

“When we flew this operation, the one thing we noticed was that our barricades were too far out,” Cloutier said. “When the trucks had to turn around, they were getting within the barricade limit, which we don’t want because we have people in there. But the trucks need space to turn around and workers need to be in there, too.”

The team relocated the work and moved the barricades, still allowing the trucks enough room to turn around and crews enough room to do their work but also providing a safe distance between them.

“We probably wouldn’t have known that without looking at the operation from up above via the drone process,” said Cloutier.

For project owner TxDOT, using drones is one more way Kiewit puts safety first.

“Safety is our priority, and we appreciate Kiewit putting safety as their priority,” Sharma said. “The continued use of drones for monitoring the work activity and utilizing it for training as well as improving the work plan shows their dedication to safety of the workers and the public.”

Kiewit has expanded its use of drone technology across several other projects and plans to continue in 2025.

A different kind of pilot

Read more about how artificial intelligence (AI) is helping sharpen the edge on another Texas jobsite in this online exclusive update.