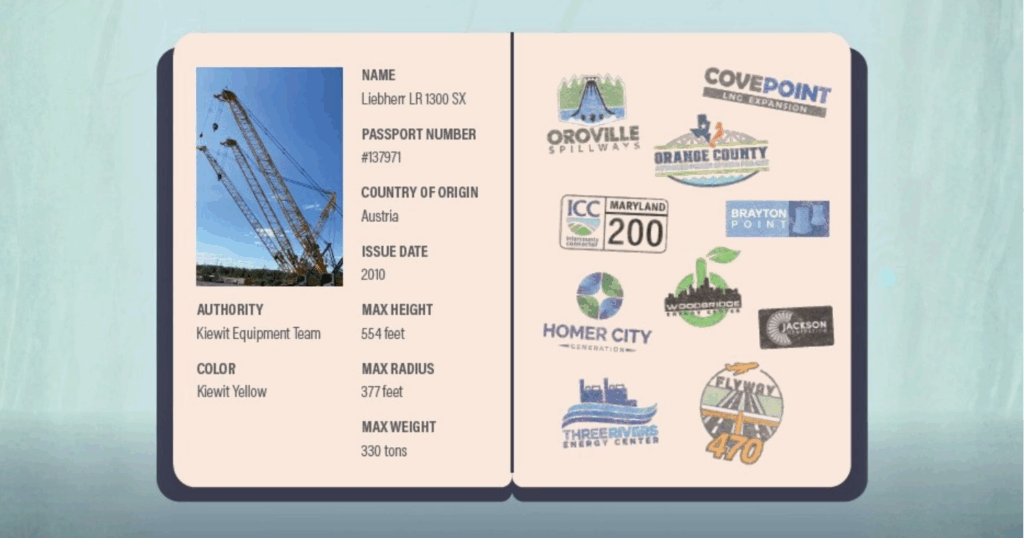

Fifteen years of reliability from Kiewit’s most trusted crawler crane

Every machine has a story. For one Liebherr LR 1300 SX crawler crane, the story spans 15 years, nearly 30,000 operating hours and some of Kiewit’s most iconic projects.

Meet Unit #137971 — a 2010 Liebherr LR 1300 SX lattice boom crawler crane. Purchased in May 2010 with a 300-metric-ton capacity and a $2.5 million price tag, it joined the fleet as part of Kiewit’s strategy to own the heavy equipment needed for the company’s most complex projects.

Fifteen years later, #137971 has fulfilled that role time and again. From highways in Maryland to power plants in New Jersey and Illinois to emergency spillway repairs in California, it has traveled the country and even been rebuilt for a second life. Its journey is more than the story of one crane. It’s proof of how Kiewit’s approach to equipment ownership turns machines into long-term assets.

A reliable start

Unit #137971 began its career on the Intercounty Connector (ICC) Contract B in Maryland, one of the state’s largest design-build highway projects. Crews were tasked with building a seven-mile toll road through heavily protected environmental areas. For the crane, that meant working in tight zones surrounded by erosion controls that required constant upkeep.

It was a debut that required precision, and, like so many first projects at Kiewit, it set the tone. The LR 1300 SX delivered and earned its place in the rotation for more.

The bread and butter

At the Woodbridge Energy Center in New Jersey, it helped build a 725-megawatt natural gas-fueled power facility on the site of a former chemical plant. The work transformed a contaminated brownfield into a state-of-the-art clean energy hub capable of powering more than 700,000 homes. The site was tight and the schedule fast, requiring precise lifts the crane was built to handle.

Assignments like these cemented the LR 1300 SX’s role.

“We always joke that the 1300 is our bread and butter,” said Brayden Pulver, equipment superintendent. “It’s going to be on every power job, and we have them everywhere. It’s our biggest in terms of quantity, and it’s the one we use the most.”

Moving an LR 1300, Pulver added, is its own kind of performance. “It’s well-choreographed — making sure everything’s in the right spot at the right time and being as prepared as we can when it gets there,” he said. “Moving a 1300 takes anywhere from 18 to 28 truckloads. Our trucking team knows what to expect, and overall they’re pretty easy to move for what they are.”

Reliability turned into reputation. The LR 1300 SX became a familiar sight on Kiewit jobsites, requested by superintendents who valued its consistency.

“The 1300 is the favorite lattice boom crawler crane of our operations by a wide margin,” said Mike Reid, crane region director. “They know how it works, and they have comfort in its capabilities and reliability.”

Milestones along the way

From Maryland, #137971’s journey stretched into some of Kiewit’s most notable projects. At Cove Point — the first liquefied natural gas export facility on the U.S. East Coast — 58 cranes operated on a 54-acre site. Each crane had its own operational zone, overseen by a coordinator, a system modeled after air traffic control at an airport.

Years later, the crane was dispatched west to California’s Oroville Dam — the nation’s tallest — after heavy rains damaged the main spillway and put the emergency spillway at risk. With nearly 200,000 people evacuated downstream, Kiewit had just 165 days to rebuild 3,000 feet of spillway before winter. The LR 1300 SX joined the round-the-clock effort, supporting a project that placed more than 700,000 cubic yards of roller-compacted concrete under intense deadlines.

From there, its career stretched across the country — projects like Jackson Generation in Illinois and into Colorado on highway work at Flyway 470. Between each move, equipment teams carried out inspections and service so the crane arrived ready for its next assignment. Each project added not just hours and miles, but also credibility to its growing resume.

Rebuild, not retirement

By 2023, Unit #137971 had logged more than 25,000 hours. Some contractors would have retired it, but at Kiewit, the next step was a rebuild.

At one of Kiewit’s maintenance facilities, crews stripped the crane down to its frame, replacing key systems and components — including hydraulics, electrical wiring and a remanufactured engine. The cab was also refurbished, and a fresh coat of paint applied. After months of work, #137971 rolled out looking almost new, with the benefit of more than a decade of operating experience behind it.

Reid emphasized that rebuilding the LR 1300 is a practical, cost-effective decision.

“Our rebuild program gives us another 15,000 hours out of each machine,” Reid said. “We replace everything — engine, pumps, hoses, electrical — and even rebuild the cab so it feels like new. Our maintenance teams especially appreciate how much easier the Tier 3s are to work on. It’s the right move operationally.”

The LR 1300 SX operated inside the Brayton Point Closed Loop Cooling tower in Somerset, Massachusetts, where Kiewit engineered, procured and constructed a 1,575-megawatt conversion from open-to closed-cycle cooling. Completed in 2013, the project also added a new substation to improve efficiency and environmental performance.

Lessons in longevity

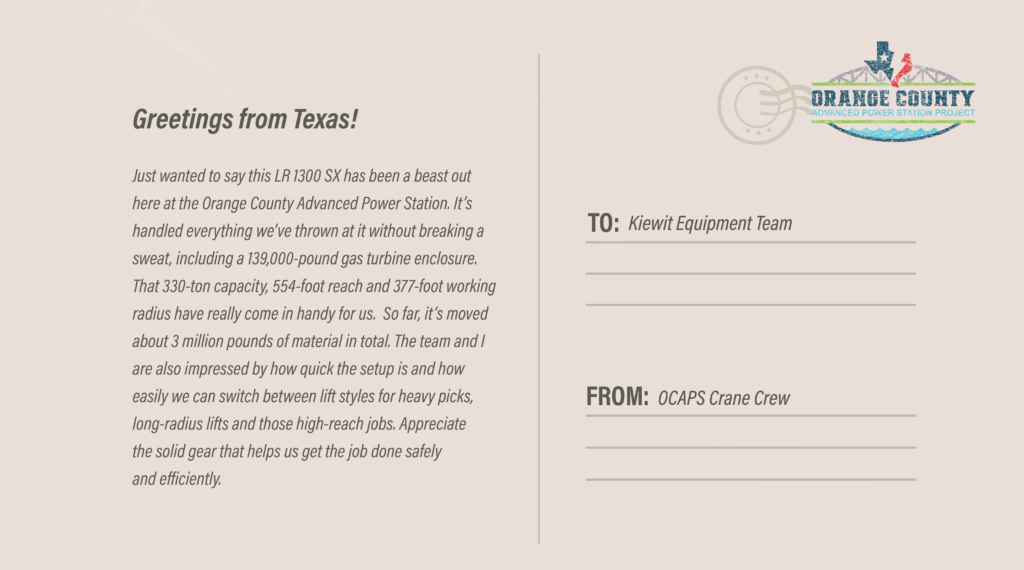

Today, Unit #137971 is hard at work at the Orange County Advanced Power Station in Texas, a 1,200-megawatt combined-cycle facility that will power more than 230,000 homes. In one of the nation’s largest industrial regions, the project marks another step toward more modern, efficient energy generation — and another chapter in the

crane’s career.

For Kiewit, the story of Unit #137971 is a reminder of why owning one of the largest and most modern fleets in North America matters. As Pulver explained, “Our biggest focus with the equipment team is utilization and availability. For us, it’s really about how we can fill a jobsite’s need with our own fleet.”

Fifteen years in, this LR 1300 SX is still proving the same lesson it did in 2010: at Kiewit, equipment isn’t just bought. It’s managed. It’s rebuilt. It’s moved where it’s needed most. And above all, it’s trusted to deliver.

Oh, the projects you will build.