The race to rebuild Oroville Spillways

In February 2017, Lake Oroville’s main spillway was compromised. After the emergency spillway was used for the first time, the hillside below began eroding. As nearly 200,000 people were evacuated, the California Department of Water Resources (DWR) began working on an emergency repair plan for both spillways at the nation’s tallest dam.

In the beginning of April, eligible contractors were given a week to turn in their bids for the Lake Oroville Spillways Emergency Recovery Project, which involved extensive reconstruction of the damaged 3,000-foot main spillway and constructing a new emergency spillway. An addendum provided little relief to the contractors, extending the bid period to 10 days.

“A 10-day bid period for a project of this magnitude was almost unheard of,” said Senior Vice President of Kiewit Infrastructure West Co. and Oroville Project Director Jeff Petersen. “But DWR provided good information and our team has a strong background in spillway construction, so we were up for the challenge.”

Three of the four shortlisted contractors submitted bids on April 15, and DWR announced Kiewit as the low bidder at $275.4 million. Less than $2 million separated the two lowest bids.

Once the contract was awarded, DWR and Kiewit faced a lofty goal: ensure a functional 3,000-foot main spillway, which could safely handle flows from winter storms, was in place by Nov. 1, 2017. Achieving this in such a short timeframe would not only be uncommon, it would be remarkable.

A month to mobilize

Kiewit’s resources proved critical. Within a month of being awarded the contract, the team had mobilized key personnel and equipment from Kiewit’s fleet across the United States and Canada. Within eight weeks, the full team of 125 staff and more than 500 units of equipment were on site, including a fully functioning concrete batch plant, a rock-crushing plant and a roller-compacted concrete (RCC) plant. The team moved in 22 excavators, 10 cranes, 13 off-road trucks, 12 dozers and 12 loaders. It set up 35 trailers for offices and provided temporary water and power for all of its operations.

The team knew that once it was given access to the main spillway, it had to be ready to begin demolition. Every minute counted.

165 days

On May 20, the countdown clock began. Kiewit had 165 days to safely repair the main spillway for the next winter season — an extremely aggressive schedule considering the quantity growth since the original bid.

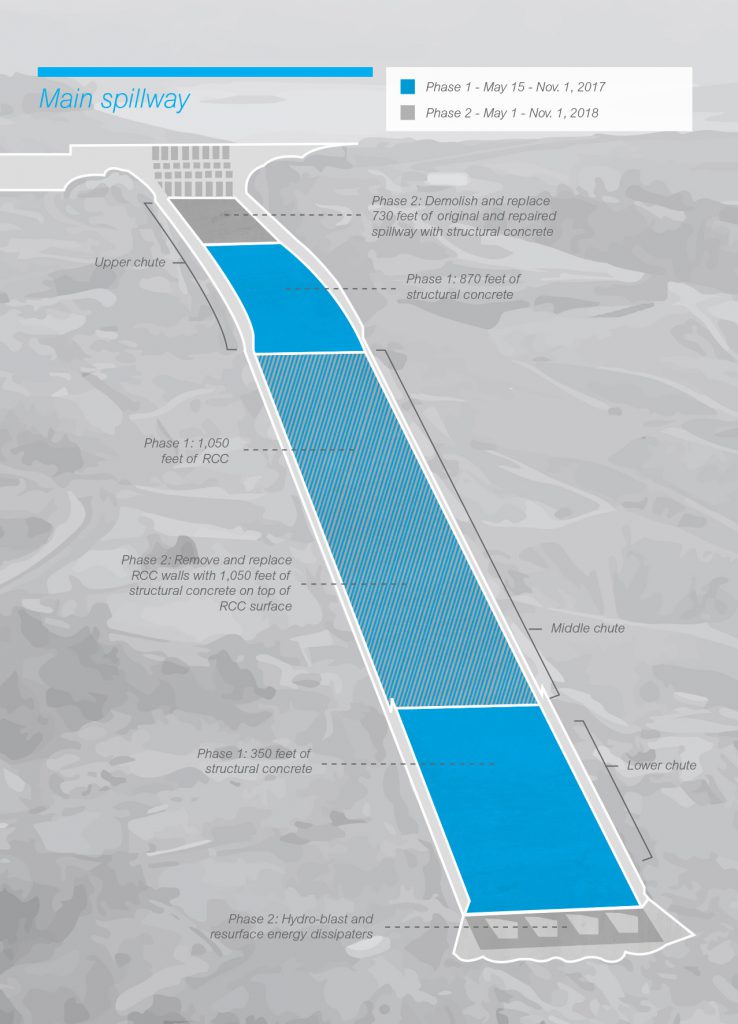

To accomplish the challenge, the team patched and reinforced the upper 730 feet of the existing spillway. An 870-foot section of the upper chute and 350 feet of the lower chute of the main spillway were completely demolished and reconstructed with steel-reinforced structural concrete to final design. The original spillway incident left two large scour holes in the most challenging area of the chute. This 1,050-foot middle section was rebuilt with roller-compacted concrete, a sturdy, yet temporary solution to ensure the spillway could safely handle flows of 100,000 cubic feet per second (cfs). During Phase 2, crews will place permanent structural concrete on top of the middle chute’s RCC surface as part of the spillway’s final design, bringing the main spillway to final design capable of passing up to 270,000 cfs in case of extreme flood conditions.

Hot dam

With the world watching, the countdown was on. “Dam cams” broadcasted construction activities live and drones were used daily to document the work. Crews worked around the clock to repair and reconstruct the main spillway. Before any concrete was placed, crews cleaned and vacuumed the foundation. Under normal circumstances, foundation cleaning is a labor-intensive job. The hazards were amplified at Oroville due to the 4:1 slope and an extreme, long-lasting heat wave where temperatures often exceeded 100 degrees.

Shade tents helped combat the heat. Crews talked about the signs and dangers of heat stress, injuries and risks. Thousands of water bottles and crates of fruit helped maintain hydration, and Kiewit provided sunscreen packets to crews daily. Kiewit implemented a Craft Voice in Safety (CVIS) program, a time-tested Kiewit way to ensure craft employees can immediately and effectively raise safety issues and take accountability for keeping each other safe. A medic was also stationed on-site in case of any unexpected medical issues.

“The safety focus on this project is incredible,” Petersen said. “We had a very fast ramp-up and worked more than 780,000 man-hours, completing Phase 1 without a recordable injury. Our team works very hard to ensure nobody gets hurt on this project.”

Northern California’s deadliest wildfire season also affected the project. Smoke hindered visibility. Some employees’ homes were evacuated and one local fire had the project under an evacuation advisory. CalFire flew their planes across Lake Oroville to refill their water tanks, and work on the spillway continued.

To the wire

Despite an aggressive schedule and extra challenges from Mother Nature, Kiewit met the Phase 1 deadline. The team finished placing the final one-foot layer of enriched RCC at noon on Nov. 1, leaving plenty of time for the concrete to properly cure before the spillway might possibly be needed.

“It was down to the wire,” Petersen said. “Phase 1 was fast, it was about teamwork and it only occurred because the contractors, the owner, the designers and the regulatory agencies all worked together with the same common goal.”

Kiewit Executive Vice President David Miles provided executive oversight to the project team. He describes the Phase 1 accomplishments as a true team effort.

“Our team only had 10 days to bid the job, one month to mobilize and then 165 days to rebuild and repair a 3,000-foot spillway,” he said. “More than 600 people put their lives on hold, working long hours, six to seven days a week in 100-degree weather to ensure there was a functional spillway in place for the winter season.”

More scope ahead

The project’s second phase officially began on Nov. 2, 2017. In Phase 2, construction crews once again need to overcome numerous challenges and accomplish two lofty goals before the next milestone — bringing both the main spillway and the new emergency spillway to

final construction.

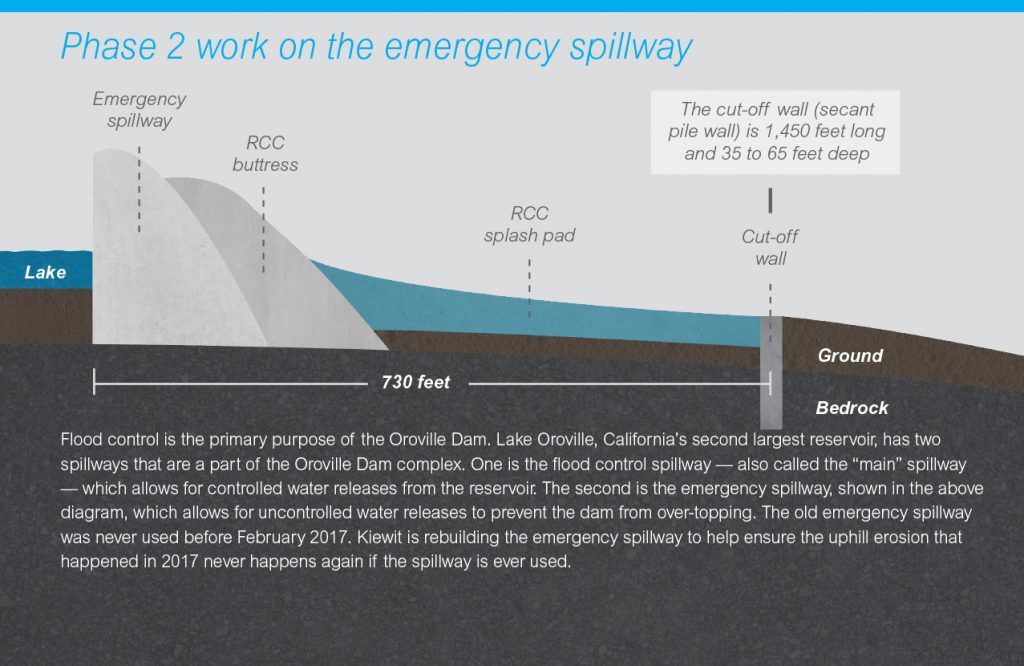

Almost 350,000 cubic yards of RCC were used on the main spillway’s middle chute in Phase 1. For Phase 2, the emergency spillway will require more than 530,000 cubic yards of RCC. Crews cleaned nearly 80,000 square yards of rock foundation in Phase 1. During Phase 2, crews will clean 160,000 square yards of rock foundation.

During the winter, efforts have been concentrated on the emergency spillway construction. Crews recently finished the secant pile wall, an underground wall of 605 individual 36-inch diameter piles, built into bedrock at depths of 35 to 65 feet.

If the emergency spillway is used in the future, the secant wall, the 850-foot-long crest cutoff wall and the 10-foot-thick RCC splash pad will prevent the kind of uphill erosion and scouring that occurred last February. More than 1 million tons of aggregate will be crushed in Phase 2 to produce the amount of RCC necessary to finish the emergency spillway buttress and apron by November.

When Kiewit once again has access to the main spillway in May of 2018, crews will demolish and rebuild the top 730 feet of the upper chute, and bring the middle chute to final design by placing a 2.5-foot-layer of erosion resistant concrete over the RCC and replace the temporary RCC walls with permanent structural concrete walls. Less than half of the slab anchors needed for the project were placed in Phase 1. The remaining quantity will be placed in this second phase. The energy dissipaters at the end of the spillway will be hydro-blasted and resurfaced. Once the main spillway is constructed to final design, it will be able to handle flows up to 270,000 cfs.

The countdown continues

“A lot of people didn’t think we were going to have a functional spillway in place in 165 days, but we did it,” Petersen said. “We have a magnitude of work ahead of us and only a few months to plan the work as DWR obtains approval of the final design. When you bring an incredible team together and work towards a common goal, together you’ll accomplish uncommon things.”