The story behind the success of the Petra Nova carbon capture project

Innovation. It’s the one word that effectively summarizes the Petra Nova project — the first commercial-sized post-combustion carbon capture system in the U.S.

Led by NRG Energy, Inc., and JX Nippon Oil & Gas Exploration Corporation, Petra Nova is a major milestone in the quest for a more sustainable energy future, leveraging the operations of an existing coal-fired power facility and a maturing oil field to collectively reduce carbon emissions. As part of the U.S. Department of Energy’s Clean Coal Power Initiative Program, the project was designed and constructed through a consortium that includes TIC – The Industrial Company (TIC), a subsidiary of Kiewit, and Mitsubishi Heavy Industries America, Inc. (MHIA).

A new era for sustainable energy

Coal continues to be a major source of energy in the U.S. Compared to other energy sources, coal-fired plants are the largest producers of carbon dioxide (CO2) emissions, which are restricted in some areas due to environmental concerns.

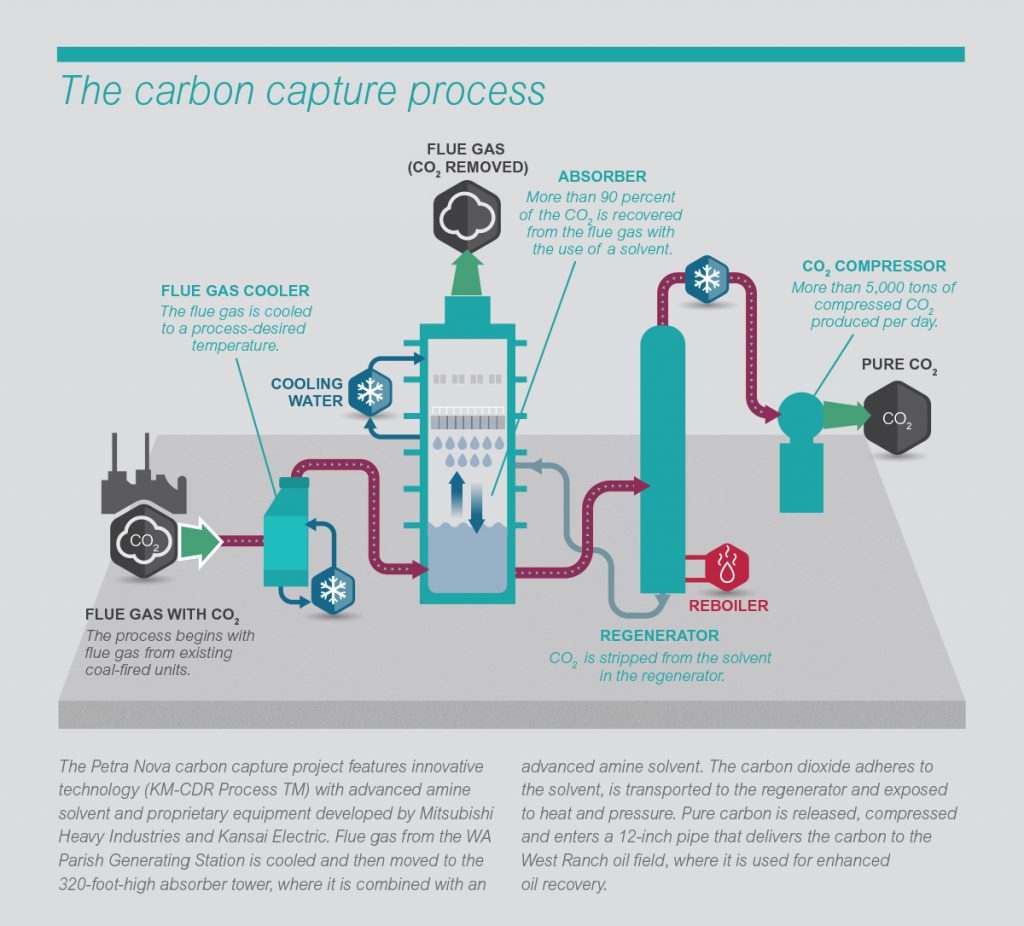

As part of the Petra Nova project, an existing power generation station was retrofitted to capture more than 90 percent of CO2 from a 240-megawatt equivalent slipstream of flue gas. The captured carbon is transported to the West Ranch Oil Field where it is used for Enhanced Oil Recovery (EOR) that has the potential to significantly increase oil production from 300 to as much as 15,000 barrels per day. On a daily basis, this process also prevents more than 5,000 tons of carbon emissions — the equivalent of taking 350,000 cars off the road.

Taking on the engineering, procurement and construction of an industry-first project is exciting and daunting. However, the expertise, teamwork and tenacity of TIC and MHIA led to a quality, on-time and on-budget project completion.

“We came into this project with a can-do attitude and quickly established open, trusting relationships,” said Bob Wolosyn, project director for TIC. “We focused heavily on making sure we had the right plan and people in place.”

Scoping it out

The scope of work entrusted to TIC required a wide range of capabilities, including engineering, procurement, site work, civil work, piping, electrical and instrumentation. TIC was also required to meticulously coordinate the integration of MHIA’s proprietary carbon capture technology into the facility.

The key structural components of the new facility included a 120-foot-tall flue gas cooler, a 320-foot-tall absorber, a regeneration system, a CO2 compression unit, and utility facilities, as depicted in the figure below.

Start-up strategy

Getting the right team in place was a top priority. TIC, along with its parent company Kiewit, held a “draft” — very similar to that of professional sports — to assemble the best-of-the-best team. Prior to setting foot on the construction site, each of the more than 1,000 workers who contributed to the project were required to attend a 10-hour orientation session. With this strong bench of skills and experience, TIC was able to self-perform nearly all of the work, allowing for better control and flexibility of the construction schedule.

Once the core team was in place, TIC set its sights on developing an ironclad plan, which relied heavily on a unified approach with MHIA, transparency with the client, and open candor throughout. Very early in the process, TIC led a line-by-line, open-book review of the project estimate to identify and assign ownership of project-related risks. The plan also called for a high level of calibration of engineering and constructability.

“We included the client in all of our communications with the engineering groups on the project. We spent countless hours in in-person meetings and conference calls with team members in Japan, where key technology components were fabricated,” added Wolosyn. “We were also able to align all engineering work into one 4D model, which helped determine any potential issues or logistical conflicts well before we put shovels in the ground.”

Additionally, project partners agreed to work off of the same playbook, offering a systematic approach and standard operating procedures in developing detailed work plans, allocating man-hours, finalizing roles and responsibilities, and monitoring progress.

“Anytime you were in the field, you saw well-planned tasks being carried out,” said Justin Mannina, TIC project manager. “From warehousing to foremen and general foreman to operators and laborers, you could always see progress in the field moving forward.”

Spurring innovation

While effective planning calls for structure and discipline, ingenuity and out-of-the-box thinking also added to the success of the project. For example, a considerable volume of on-site welding was needed — a practice that is generally time-intensive — to meet quality standards. Workers were challenged to explore new welding techniques, ultimately conducting research on and using a semi-automatic welding process. With a modest amount of training, welding productivity increased by about 50 percent.

New mobile technology was also introduced on the construction site, bringing back-office operations, such as payroll and inventory, out into the field. Specifically, construction foremen were equipped with mobile devices that allowed them to monitor daily costs, approve time cards, report quantities, process payroll and assign work orders.

Increased productivity was achieved by constructing sections of the cooling tower in a nearby laydown yard and then using a platform trailer and crane to set in place.

Access to an in-house fleet of cranes and other equipment maximized costs and streamlined the construction schedule.

Sustainable success

The successful completion of Petra Nova provides the groundwork for other systems that might use carbon in their operations, beyond EOR. As new processes emerge, TIC and MHIA are well-positioned to design and construct these projects, due in large part to early contractor involvement and cross-discipline training that eliminated silos within the organization.

“Well before we mobilized to the construction site, I worked in the office with the engineering team to fully understand the project and facilitate constructability reviews,” said Omar Chavez, construction superintendent at TIC. “From there, I was entrusted to handle key operations in estimating, hydro, pipe and managing subcontractors. It has been a huge opportunity to advance my career in the construction industry.”

Overall, through teamwork and a unified approach, the Petra Nova project was completed on time and on budget. More than 1.78 million man-hours were safely completed without a single lost-time incident. The construction scope of work had less than one percent of budget in change orders, and TIC was recognized as the 2016 Engineering & Construction (E&C) Supplier of the Year by NRG.

“The transparency, open dialogue and positive attitude permeated throughout the project teams, resulting in an atmosphere of cooperation at all levels,” said Jim Tharp, NRG project manager. “This is one of the best — if not the best — projects I have worked on in my career and I believe this is largely due to the working relationship between all of the project partners and vendors and the mutual respect that we have for each other as we strive to deliver a quality project safely.”