Evaluating purchases based on cost versus value is a part of everyday life. When it comes to buying office supplies, the lowest price might suit your needs (a paper clip is a paper clip, right?). But when buying a car, which involves many options and a greater financial risk, you will likely base your decision on a variety of factors beyond the price tag. How many miles per gallon? Are the seats comfortable? Should you buy or lease?

The procurement process for infrastructure projects today is much like buying a car. There are a number of options for project delivery, and it’s unlikely that a one-size-fits-all approach will provide the best results over the life of the project.

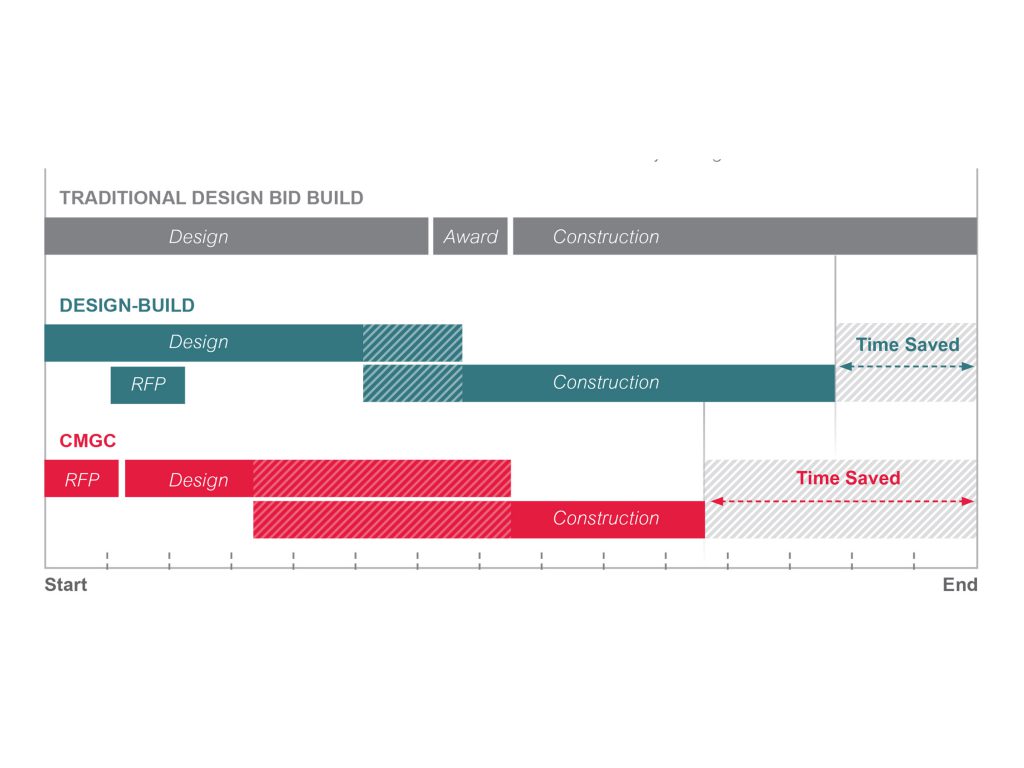

Construction projects continue to become more complex with the growth of multi-modal systems, more densely populated areas, aging infrastructure and more stringent regulations. Many of these challenges are being addressed through the Federal Highway Administration’s “Every Day Counts” program, whose mission is to drive innovation in transportation projects, including the use of the Construction Manager/General Contractor (CMGC) project delivery method. For more than a decade, Kiewit has successfully delivered hundreds of projects using CMGC across transportation, water/wastewater and building markets. As the model has been growing in its applicability, it has become the best model for many of today’s construction projects.

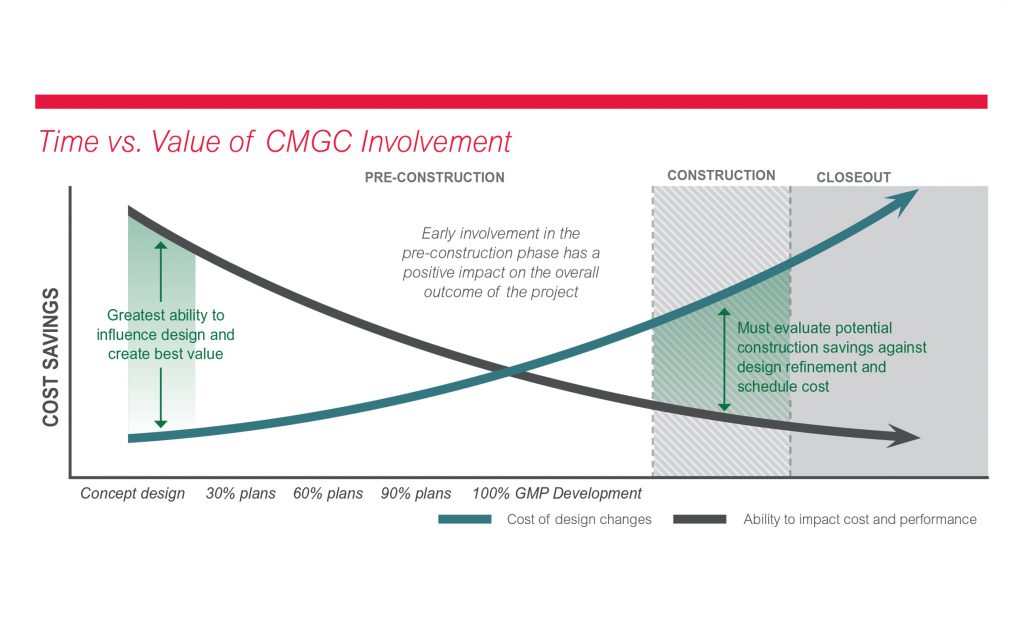

As a leader in CMGC delivery, Kiewit provides the stability, predictability, flexibility and overall best value to clients and partners. Kiewit’s pre-construction services include constructability reviews, value engineering, cost estimating and scheduling, along with state-of-the-art software systems that provide detailed, real-time information. These services, technologies and expert assessments allow the client to make informed, value-based decisions that result in successful, cost-effective projects.

What is CMGC?

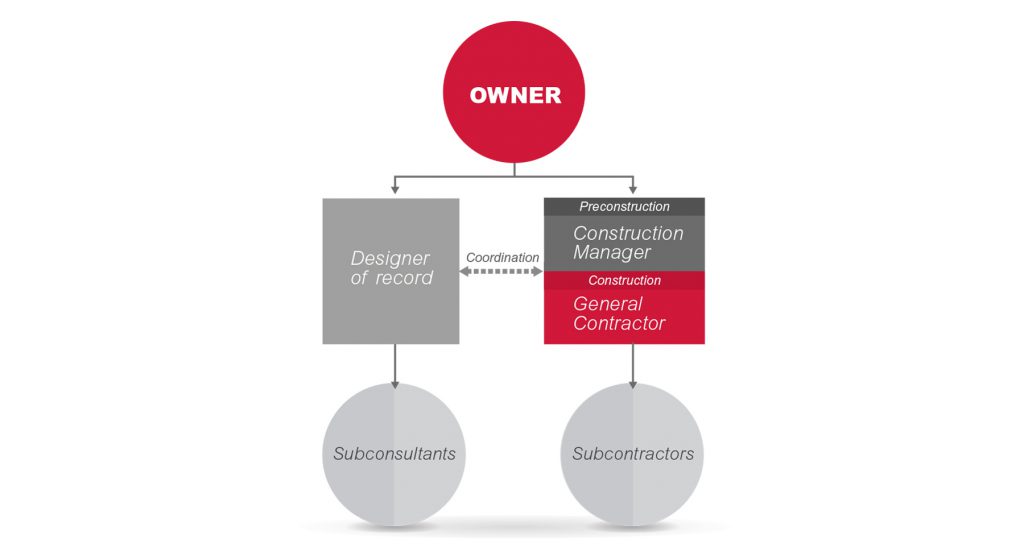

CMGC is a project delivery method that optimizes efficiency in the design, schedule and cost on complex or technically challenging projects. The client — typically a state, regional or municipal agency — selects and manages separate contracts with the designer and the contractor, who is brought into the process in the very early stages of the project. A contractor has two roles, acting as a construction manager during pre-construction services and as the general contractor during the construction period.

How does it work?

CMGC procurement methods can vary greatly from state to state, but two aspects are consistent. First, the client must be one of the growing number of agencies with specific CMGC authority, enabling legislation and an effective CMGC process. Second, when selecting a contractor, the client divides projects into two phases: pre-construction and construction.

For pre-construction services, the client generally issues a Request for Qualifications. Then, contractors submit a proposal that is evaluated primarily on their experience and qualifications. The client may also require in-person interviews where contractors’ management teams can present their capabilities, innovative concepts and solutions. During the interview, many clients will also ask contractors to respond to real-life project scenarios, providing insight as to how well the client and contractor will work together, manage conflicts and overcome challenges. Finally, the client might request a price component, most commonly in the form of a construction management fee. Once the selection is made and the pre-construction process of design innovation, constructability, schedule, risk mitigation and cost optimization has culminated, it’s time to start construction. The client and the contractor will work to negotiate a Guaranteed Maximum Price (GMP) for the construction contract.

“One of the barriers to the adoption of CMGC has been the misconception of an uneven playing field that might not lead to the best overall pricing,” said Joe Wingerter, senior business development manager at Kiewit. “While the criteria for pre-construction services selection is primarily based on qualifications, the client maintains the ability to go out for bids and select a different contractor for the construction work if they believe they are not getting the best value and price. The pre-construction phase is really like an extended interview — the contractor has to demonstrate value and bring the best people, solutions and cost-saving measures to the table to stay in the game.”

What are the benefits?

Terry Cole, senior operations manager for Kiewit, has been working on CMGC projects for more than a decade and has seen the benefits first-hand.

“CMGC allows the client, designer and contractor to work together to find the best solution for a project that will in turn give you the best quality and price at the end of the day. It’s really that simple.”

With the client, designer and contractor all at the table at the same time, the collective team can meticulously plan the project, identify risks, optimize the construction schedule and reduce costs. Also, unlike a design-build project, where the contractor oversees the designer, the client has direct control over the design. This aspect of CMGC is coveted by many clients since it reduces risks and increases project certainty.

The client, designer and contractor are tasked with an exacting approach in identifying, managing or eliminating risks. On most projects, a risk register is used to document all of the possible scenarios that may affect the outcome of the project, such as unexpected utilities, unknown permit conditions and right-of-way issues. The team carefully evaluates each risk: What is its probability? How will it impact construction? Can it be avoided with design modifications? Who will be responsible for managing it? How much will it cost? Ideally, this analysis occurs when the project is at 30 percent design and then revisited when the design is 60 and 90 percent complete.

“On a recent project, the team initially identified roughly $40 million of risk-related costs,” said Will White, vice president of operations at Kiewit. “By the time we reached 90 percent design, these costs had been reduced to $6 million as a result of working with the client and designer to make adjustments that would eliminate certain risks. In traditional bid-build projects, these costs would likely hit the client toward the end of a project as change orders. With the level of certainty and cost savings that can be achieved through CMGC, it is possible to avoid costly change orders.”

The fluid discussions that occur during pre-construction also drive innovative solutions.

“The pre-construction phase gives us time to look at a lot of different options and cutting-edge solutions, which are documented in an innovations log that reflects more than a decade of our CMGC work,” said Craig Briggs, senior vice president at Kiewit. “Across the board, these solutions and constructability reviews have reduced project costs by 20 percent or more.”

CMGC also gives the client the flexibility to divide construction up into multiple work packages. This can help keep projects moving forward if the client is faced with budget constraints, extremely complex work or stakeholder conflicts that are still being resolved. For each work package, the client negotiates a GMP or lump sum price with the contractor. If the client and contractor are unable to reach an agreement on the GMP, the client has the ability to put the work out to bid.

When all project stakeholders are bought in and committed to the success of the model, CMGC’s ultimate resulting benefit is the cost-effective, safe and timely delivery of a complex infrastructure project to its end user.

Kiewit won the contract for permanent flood repairs to U.S. 34 in Colorado after completing temporary, emergency flood repairs ahead of schedule in 2013.

The Fast Fix 8 project included installing eight new bridges in Nashville’s busy downtown corridor. The project was completed seven months ahead of schedule.