When making decisions, most of us typically draw upon the knowledge, skills and understanding that we’ve collected through the years. This, after all, is the very definition of experience. While personal experience can be valuable, it can also be limiting.

What if there was a way to harness the collective experience of thousands of employees to fine-tune decision-making to a science? At Kiewit, there is — by using data-driven solutions managed in-house by Kiewit’s data services organization.

Over the past decade, Kiewit has gathered, refined and utilized data, amassing over 200 million work hours’ worth of information, equivalent to the knowledge gained from 3,766 people’s 30-year careers.

“We are well established. We have large volumes of data and are aggressively pursuing prediction systems,” said Matt Pappas, Kiewit’s chief data officer.

“We got in early and now we are ahead in the big data and artificial intelligence movement.”

Pappas characterizes Kiewit’s data services group as a holistic data management organization focused on making Kiewit the premiere data-driven organization in the construction industry. Its mission is to make sure employees have the right data, of the right quality, with the right level of analysis available to them at the right time.

By making data-driven decisions, the company has the power of insight that enhances human capabilities to help uncover patterns, trends and correlations. This information helps projects finish on time and within budget while keeping everyone safe.

However, raw data alone is not what makes this possible. It takes data scientists, data engineers and analysts to manage, understand and consistently improve the data quality to reach the desired outcomes.

The Humans Behind the Machines

When it comes to assembling the data services team, leadership is poised to harness the talent of the young minds of recent graduates. Data Scientist Kati Stanzel is evidence of that.

As a junior at the University of Nebraska Omaha, she was excited to start her summer internship with Kiewit. But it was 2020 and she felt nervous watching as other companies canceled their internship programs while the COVID-19 pandemic was wreaking havoc on the world.

Rather than canceling, Kiewit pushed forward with a remote intern program. In June 2020, Stanzel put on her mask, picked up her laptop and hit the ground running. She didn’t know it then but the internship would change her life.

After several months on the job, Stanzel was encouraged to join a machine learning project, which led to an invitation to apply for a position within the newly created data science team at Kiewit. She applied and became a full-time data scientist after her graduation in 2021.

“Kudos to the people who saw my talent and were able to say, ‘this talent needs to be in this department and will succeed’. The fact that people would do that for me is amazing,” she said.

In the short years since becoming a full-time data scientist, she has been able to work on key projects. “Our team is so passionate about the different projects we work on. I think that’s why we are successful — because we care. We have the heart and the drive to succeed.”

Data-Driven Decisions

One program Stanzel has been able to work on as a data scientist is the Predictive Estimating Tool.

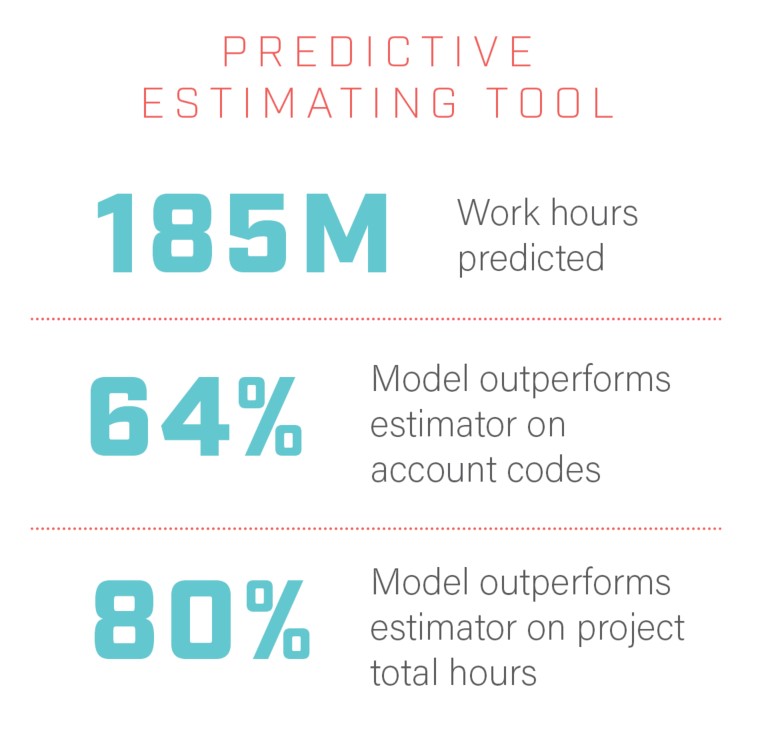

The tool has helped predict billions of dollars in estimates, ensuring cost and schedule certainty for clients by estimating the work hours per quantity, staffing ratios and tooling ratios correctly. Having an accurate estimate keeps costs low for clients and helps Kiewit bid work at the right price.

Pappas emphasized the value of data-driven decision-making and noted Kiewit is changing the way estimating has historically been done.

“The construction industry is almost entirely estimated by humans right now,” said Pappas.

How do humans stack up to the machine? Pappas has crunched the numbers with a technique called a “backward walk.” It looks at what the human estimated versus the algorithm.

“On completed work that has been run through the predictive estimating tool we found that 64% of the time the human will get outperformed by the model,” he explained.

The model’s algorithm can calculate multiple factors to get to a rate based on job size, location, weather data and more.

“A human alone just can’t do that,” he said.

The technology also allows estimators to run multiple scenarios to find what works for them to get the right cost.

“It really harnesses the power of everyone’s experience and not just the experience of the people on the estimating team,” he said.

However, the tool doesn’t replace human experience. Pappas explains that the tool can serve as “a really strong second check” to traditional manual estimating. The model will tell the estimator whether the estimate is too aggressive or too conservative in certain areas.

Watchdog Program Serves as ‘Early Warning Sign’

Six years ago, Kiewit created Watchdog, an app that tracks financial, schedule and hour-based metrics month-over-month for Kiewit projects. Vice President and Operations Controller Dave Freeman says it’s a first-of-its-kind in t he industry.

It uses an algorithm to predict whether a project is at risk of going over budget.

In the last three years, the app has detected 94% of job losses, which Freeman explained is important to catch because when the cost is wrong, the schedule is wrong. The ripple effect will lead to an unhappy client.

“It can be used as an early warning sign,” he said.

The Watchdog program includes a Job Schedule Report (JSR) function, which predicts issues with extremely high accuracy by forecasting work hour needs using cost and schedule data.

Why the need to predict the future? Predicting problems early can help project teams course correct and solve issues before they become problems.

Data Can Improve Jobsite Safety

In May 2021, Kiewit published the Safety Risk Forecast (SRF). According to Freeman, it is one way to provide “powerful predictions” to keep workers safe. Kiewit’s data scientists worked closely with safety and operations leaders to develop the model. It uses data to predict incidents that could happen in the near future. The program takes several factors into consideration (the “hurt rate impact”), including timing of future work, ratio of inexperienced staff, risky work hours and more.

“It’s truly a predictive tool where in the past we’ve been very lagging in looking at all of our indicators and different types of data elements,” said Kiewit Corporate Safety Director Alicia Edsen. “Now we’re able to really see what’s driving that risk.”

The SRF gives project teams with the lowest safety ratings an opportunity to fix the most critical risk factors.

“We’re not just giving them a tool that says, ‘Here’s your risk drivers, go figure out what to do with it.’ We’re also giving them recommended best practices, resources and training that we know work to take action,” Edsen said.

The Associated General Contractors of America (AGC) awarded Kiewit first place for this tool during the 2022 Construction Safety Excellence Awards (CSEA). The company was given the award in the heavy civil category for its commitment to safety and occupational health management and risk control.

Kiewit also uses data for the Life Saving Action (LSA) program, which draws from 60 million hours of data to prevent job site incidents. It works by using data to identify the riskiest categories of work, then gives context for what project teams can look out for to stay safe.

Kiewit has studied the effects of putting the data into action.

“We wanted to see the impact if someone goes through a project site and assesses it — to see if LSA identified risk behaviors are happening,” said Pappas. “We found there is a corporate reduction in serious incidents by all projects meeting the corporate standard assessment rate.”

“The team discovered that on the day an LSA Assessment is done, the site has a five time less likelihood of having an incident compared to a day when they don’t do a single assessment,” he added.

With that discovery, Kiewit is now gearing its tools to help project teams understand how many LSA assessments should be done since it appears to suppress severe incidents.

“The LSA program is well-established on our projects, and we have the technology at our fingertips to assess ourselves, grow and improve,” said Kiewit Infrastructure Co. Senior Vice President Bill Bodnar, a senior operations leader for the organization.

The Kiewit data services team is also examining how to use data to prevent job site fatalities. It has built a Fatality Study using data from fatalities that have happened over the past six decades. It breaks down each project and the rate at which they are most likely to have a fatality. Historically, the accuracy of the data is at a 50% error rate.

The report is provided to leaders who can enact change in the identified risk areas.

Analyzing, understanding and acting on all of this data will continue to be an important part of Kiewit’s pursuit of its goal of Nobody Gets Hurt.

“As we look as safety leaders in the organization and try to look for different things to truly get us to the next level in safety, these data solutions are going to help us do that,” said Edsen.

Looking Forward

Stanzel feels inspired for the future when she is helping build data driven tools requested by employees out in the field. She sees her role as walking hand-in-hand with field employees to be safer and more efficient using the tools the team creates.

“When I drive by a Kiewit construction site, all I can think of is the models that our team has built to help make the field as successful as possible,” she said.

Since Stanzel joined the data scientist team in 2021, the team has grown significantly.

“To be a construction company that focuses on data-driven decisions with that many data scientists shows Kiewit is paving the way in the industry,” she said.

Stanzel believes they are just scratching the surface on what’s available in Kiewit databases.

“This makes me excited for the future because if we’re able to extract some of that data and transform it in the way we need to in order to model it, then we will be in a tremendous position to further help the business.”

Pappas agrees with Stanzel’s outlook and noted the company is putting the time, resources and investment into unlocking the full potential of the data it owns. In the future, Pappas sees Kiewit harnessing data-driven innovation to offer client solutions, such as pioneering new markets with cost-efficiency through risk-taking supported by algorithms and AI.

“Thoughtfully managed data-driven algorithms will bring about unparalleled accuracy in decision support that we have never experienced in our industry,” he said. “I’m excited about where the tools we’re building will take us.”