You won’t get too far across the Lonestar State before coming upon a cattle ranch or row crop.

As a leading exporter, the Texas Department of Agriculture reports that 86% of its land is dedicated to agricultural production of some kind. Most often you’ll find hay, cotton or grain, but there’s a stretch of farmland across three counties in Northeast Texas that stands out a bit from neighboring fields.

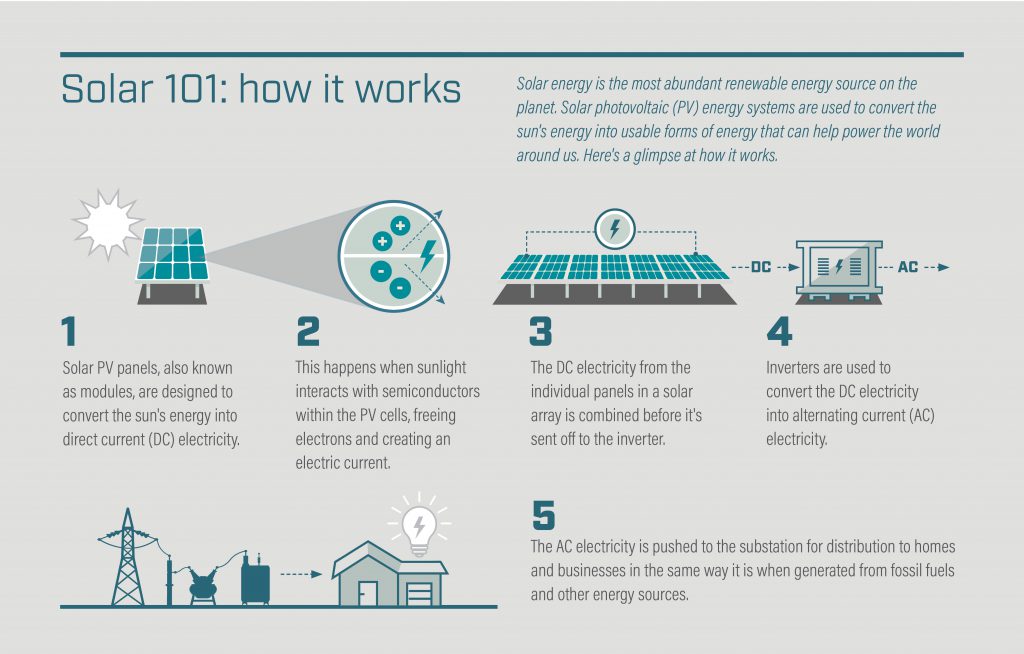

“Instead of planting crops, we’re harvesting ions.”

Area Manager Norm DeCastro oversees the Samson Solar project for TIC, The Industrial Company, which is a subsidiary of Kiewit Corporation.

In July 2020, DeCastro’s team started converting 4,200 acres of farmland into the United States’ largest solar energy farm on behalf of Invenergy, a global developer and operator of sustainable energy solutions. Eventually, this strip of land will generate an unprecedented amount of clean, sustainable energy — enough to power up to 300,000 homes.

Not only is TIC building this massive solar farm safely and efficiently, it’s improving how this type of energy is brought to the masses.

“The industry as a whole approaches solar work with manual-labor-intensive methods,” explained Samson Project Manager Stephen Hambleton. “It involves moving materials with people instead of machines.”

The team realized early on that the industry is ripe for improvements, so as it builds Invenergy’s massive solar farm, it’s also challenging industry standards to perfect the process and rewrite the solar playbook.

“We have put a heavy emphasis on bringing innovation to the solar market,” said Hambleton. That means designing and testing new efficiency and safety methods without disrupting operations.

“We knew we couldn’t waste this opportunity,” he continued. “But because the project team will work over 1.4 million hours in 12 months and peak at over 700 craft, we needed to keep the core team focused on safety and schedule.”

So, they assembled a highly talented and motivated team to drive innovation. Enter Jacob Metzger and his Innovation and Continuous Improvement Program.

Metzger, known on the project as the “innovation chairman,” uses his past experiences as a construction manager and superintendent to his advantage — made obvious through his “boots on the ground” approach.

Working with the field team’s direct feedback, Metzger oversees the ideas that make it off the whiteboards and spreadsheets and into fabrication and onto the job site. Once a method proves efficient, it is implemented on a broader scale.

Documenting these practices is key in creating a new solar playbook for future projects.

From the ground up

The innovative work at Samson Solar started as soon as the project team began driving posts into the ground. Each post supports the racking systems and solar panels, but the installation methodology isn’t one-size-fits-all for every post.

Because of the thousands of acres of diverse soil Samson Solar covers, drive times for posts differ throughout the site. No matter the geotechnical aspects of the soil, placing posts at the correct depth has been made easier with the use of new software and equipment.

There are 15 PD10 pile driving machines on-site to install posts into the ground. Each is guided by an RDO/Carlson GPS. This system guides each installation and can be remotely updated with the X, Y, and Z coordinates for each post. Two coordinates ensure the post is installed at the correct location and the third designates the depth.

The traditional industry standard for operating a PD10 is a three-person crew consisting of a rig operator, a skid steer operator and a laborer on the ground to feed the posts into the machine. But TIC found a safer, more efficient way to install posts with a two-person crew.

On the Samson site, the crew uses a grapple attachment on the skid steer to grab the post and feed it into the machine. Now the operation no longer requires a laborer on the ground, interfacing with the machine. This safer method increases efficiency by 30% and cuts 16,000 direct hours from the project.

Crunching the (massive) numbers

“This work is as much like manufacturing as it is construction,” said DeCastro. Not unlike an assembly line, each part of the process relies on the last. And there are so many parts to manage.

It takes an expert logistics superintendent like Jamie Swigart to keep the process running smoothly with three phases of work that, at peak delivery, involve 8,000 trucks with 40 to 60 deliveries a day, five days a week.

“In solar, due to the volume of both material and acreage, unloading materials as close to the work as possible is more pronounced since the area is so vast,” said Swigart. “This brings the logistics side of materials management to the forefront.”

Swigart and the rest of the team make sure each part falls perfectly into place, including the 2.3 million solar panels that make up the project.

Each panel varies from 340 watts to 500 watts and is about 3.5 feet by 6.5 feet in size. They’re also bi-facial, meaning they can collect direct sunlight from the top and reflected sunlight from the bottom.

The panels rest upon tables consisting of the steel posts and the structural racking system that supports them. The tables are also equipped with a drive system that shifts the panels toward the sun to increase efficiency during daylight hours.

TIC is also installing 70 miles of chain link fencing, 200 inverter skids and about 7,000 miles of cable throughout this project.

Approximately 500 pieces of company-owned equipment are also located on site. This includes scrapers, excavators, loaders, articulating dump trucks, skid steers and utility terrain vehicles.

Two-man crews drive about 100 posts into the ground each day using this new grapple method. The 15 machines on site place around 1,500 posts daily.

Teams will install a total of 2.3 million solar panels on the 4,200-acre site, enough to power up to 300,000 homes.

“Because of the area, the logistics and the sheer volume and size of the project, it really takes a company like us to ramp up to a project of this scale, get the equipment and drive the efficiency that you need here,” DeCastro said. “Anybody can hire a bunch of people and turn them loose on 4,000 acres. But we do it safely, effectively, efficiently and deliver a quality product.”

Samson Solar is expected to peak September 2021, with more than 700 craft employees anticipated to be on site, many hired locally.

Samson Solar is only the beginning.

“With this job being our first mega solar job, we want to make sure before we leave here that we’ve established a good set of ground rules and standards that we can start implementing on other jobs,” said Metzger.