Solar power is the fastest-growing source of new energy in the country, according to the U.S. Department of Energy. With over 50 solar projects completed in North America over the last 15 years, it’s also a burgeoning sector for Kiewit.

The Madison Fields Solar Project is the latest of several solar jobs for Kiewit Corporation and its subsidiaries in Texas, Nevada and now central Ohio. Located in Pike Township in Madison County, Ohio — about 30 miles west of Columbus — the project is a 234-megawatt solar-powered generating facility.

The facility, which will take up about 1,100 acres of a 1,932-acre project area, is expected to generate power for up to 35,000 households when it goes online.

Working with project owner Savion Energy, Kiewit Power Constructors Co. (KPC) has been leading an EPC (engineering, procurement and construction) contract since November 2022.

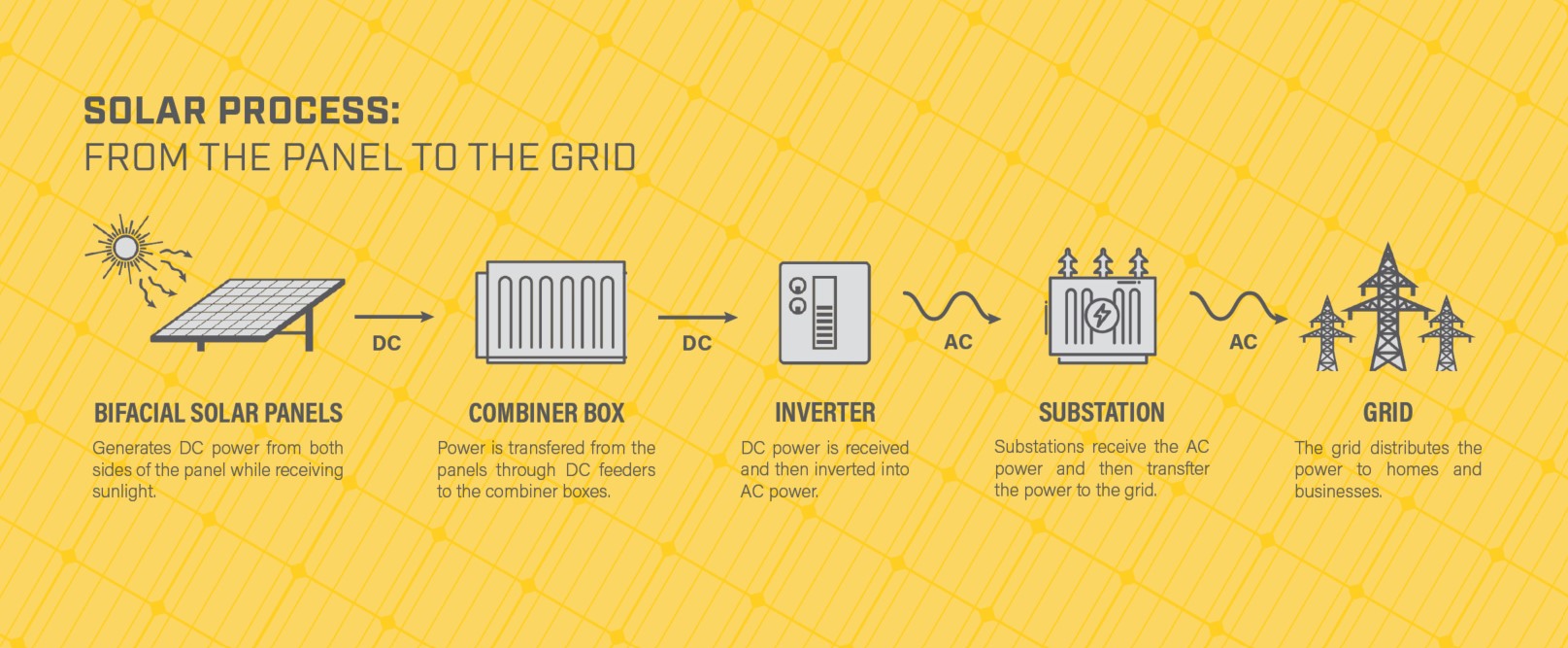

The project scope includes 15 miles of access roads to the power blocks, driving 80,000 piles to support the racking system that holds and tracks the photovoltaic (PV) modules, installing 420,000 bifacial PV modules to produce power, running over 2 million linear feet of DC and AC cable and placing 45,000 linear feet of permanent fencing.

Nimbly Navigating Challenges

Turning the job over on a compressed schedule — only 13 months from breaking ground to pushing power back to the grid — meant finding nimble solutions to challenges.

When work began on the access roads to be used by construction crews and eventually by facility personnel, fickle winter weather meant temperatures could swing from minus 10 degrees Fahrenheit to 60 degrees in less than a week.

“We had a lot of freeze-thaw cycles through December, January and February, so it was really a struggle just to build access to our work,” said Project Manager Nick Schiegner.

At times, the cement didn’t have enough time to hydrate and cure prior to freeze-thaw conditions taking place, resulting in a substandard reaction.

The solution: adding quicklime, a chemical compound derived from natural limestone deposits to the mix to kick the cement into heating mode and the right consistency. To protect the surface, they used 5-inch-thick hard plastic matting for temporary craft parking.

Updating the Game Plan

Accommodating equipment delivery delays was another challenge. Working closely with the project owner, the team knew in advance that the PV modules, which collect sunlight and generate power, would be delayed.

“We have a really good rapport and relationship with the client,” said Schiegner. “They notified us immediately of any issues and we were able to pivot and update our game plan.”

That ability to pivot was thanks to training the crews on other tasks while they were waiting, said Hunter Harlow, electrical general superintendent.

“We were very strategic with saying ‘Yes, we’ve got a crew of guys that does the scope of work, but we can cross-train these guys to do this other scope of work.’ It was easy for us to leverage different scopes, and where we did have material, we could start work.”

Staying Ahead of Schedule

The toughest stretch of the schedule was undoubtedly the push at the end to commission and performance-test the facility, said Schiegner. “With a mere three months between the plant backfeed availability to substantial completion, we knew we had to think outside the box.”

The team mobilized a 4MW equipment package, complete with generators, transformers and a load bank, known as a grid emulation system. It would imitate backfeed power and grid-loading capacity to start the commissioning process six weeks prior to backfeed.

With the equipment set up near the project’s substation, the team was able to commission each circuit one at a time, completing many activities ahead of schedule.

Construction Manager Allan Fuhs also credits KPC’s experience with another recently completed solar project with helping the job be successful.

Working with the Best

“In the world we live today, getting the right people here to work is tough, not just in the middle of Ohio but across the country,” Fuhs said.

About 13 foremen followed the job from another project to Madison Fields, which meant little retraining was needed.“The best thing about knowing foremen in central Ohio, they know a lot of great people that are willing to come out here and help us out,” Fuhs said.

He says he’s proud of the team that they put together. “They’re only going to want the best to work with them and we only want the best to work with us.”

The Best of Both Worlds

An innovative pilot project at the Madison Fields Solar project offers new ways to look at the future of farming in the form of agrivoltaics. A combination of “agriculture” and “voltaics,” the word means using land for both agriculture and solar photovoltaic energy generation.

Four blocks have been set aside at Madison Fields to be designated for agrivoltaics, said Hunter Harlow, electrical general superintendent.

It’s an exciting project to be part of, Harlow said. “For us, this is the first project where we’ve had four blocks like that and it’s kind of a test bed for our client. If it’s wildly successful, they’re definitely going to be looking at doing that on a much larger scale for some projects down the road.”

Madison Fields’ owner, Savion Energy, is partnering with researchers from Ohio State University to study the potential for hay and alfalfa production with solar grazing. The team recently was awarded a grant from the U.S. Department of Energy to support this research.