Tools that fit the way Kiewit works

Imagine turning a task that once took weeks into something that can be done in hours. For Kiewit estimators, engineers and field teams, that’s not the future — it’s happening now.

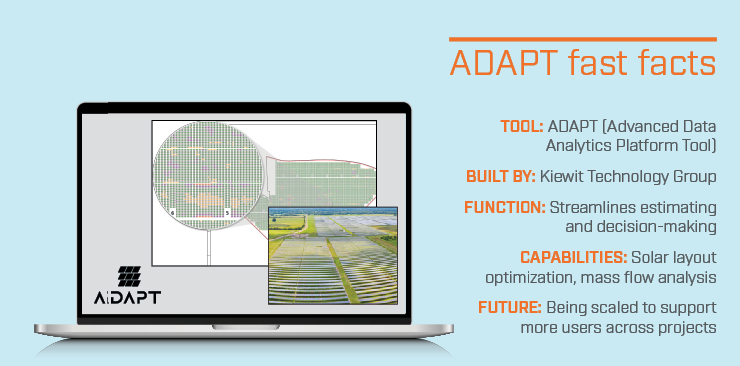

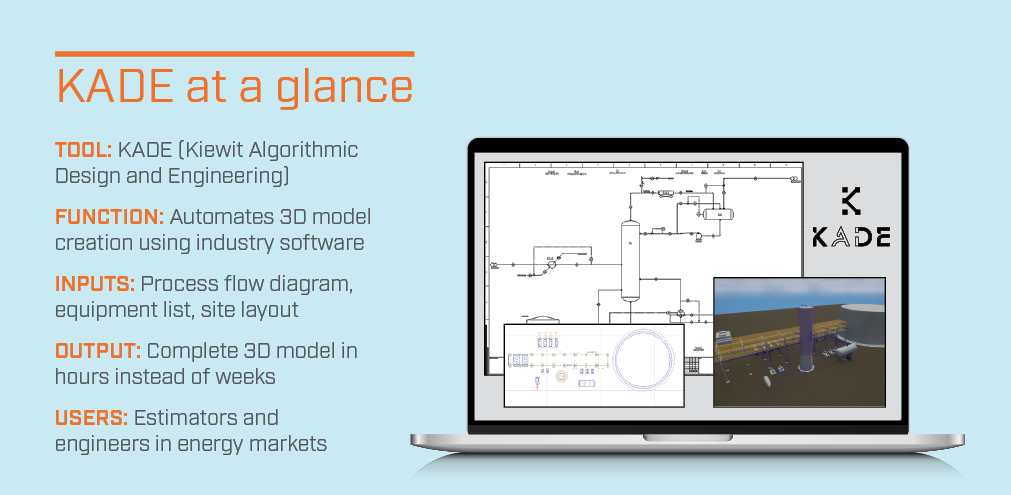

The shift comes from two powerful tools, fueled by artificial intelligence (AI): KADE (Kiewit Algorithmic Design and Engineering) and ADAPT (Advanced Data Analytics Platform Tool). KADE was tailored from an off-the-shelf solution, while ADAPT was developed entirely in-house. Both use deterministic AI to meet real project needs.

From design to execution, these tools are transforming how work gets done, making it faster, smarter and better. This isn’t just a tech upgrade; it’s a rethinking of what’s possible on the jobsite, and Kiewit is leading that change from the inside out.

KADE: Smarter design from the start

KADE speeds up 3D model creation for complex industrial facilities. It starts with a few key inputs: a simple process or block flow diagram (which shows how materials move through a facility), an equipment list and a rough site layout. From there, it automatically generates a full 3D model. These models act as digital blueprints, helping teams catch conflicts, explore design options and collaborate more effectively before construction begins.

“KADE was built to follow the same processes an engineer or designer would, using the same software and data,” said Matt Lawrence, director of engineering technology solutions for Kiewit Technology Group. “The difference is automation. It streamlines the work and delivers the same quality output you’d expect from a person, but in a fraction of the time.”

For over a decade, Kiewit has relied on trusted, industry-standard design tools, but mostly in manual ways that left their full potential untapped. That changed when Lawrence asked, “What if we used them differently?”

With leadership support, that question led to KADE.

“We have unlocked industry-leading efficiencies by combining algorithms based on Kiewit Engineering Group Inc. (KEGI) standards and processes with automation,” Lawrence said.

By speeding up design, KADE allows teams to explore more options, iterate quickly and engage clients earlier, when changes are easier and more cost-effective.

The benefits go beyond single projects. In recent pursuits, estimators have used KADE to build multiple models at a pace that used to be impossible, helping them pursue more work.

“They’re all in on this because they’re thinking, ‘Wow, if we could do this, we could optimize our manpower better and we wouldn’t have to use all of our available resources just to create one proposal,’” Lawrence said. KADE’s speed allows estimators to put more “hooks in the water” (more bids).

But with that speed comes a shift in expectations, one that not everyone embraces right away.

“The perspective can be, ‘Well, I only have one job, and this job is supposed to last me for eight weeks, but you just completed it in eight minutes. Now what do I do?’” he said.

It’s a common reaction to new automation. Watching a tool do in minutes what once took weeks can feel unsettling. But Lawrence said the goal isn’t to replace people’s work; it’s to remove the tedious steps so they can focus on critical thinking and, ultimately, win more work.

ADAPT: A custom solution

While KADE enhances efficiency using existing industry tools, Kiewit recognized the need for a solution not covered by off-the-shelf software. That’s where ADAPT fits in — a sister tool built from the ground up to meet specific project needs.

Ryan Jisa, who leads ADAPT’s development, describes it as a custom platform built to bring structure to complex estimating.

“You don’t have to know everything — the platform guides you through the process and taps into powerful algorithms along the way,” he said.

The current version of ADAPT can run only one or two large jobs at a time, but Jisa said the team is working to change that.

“My focus has been on transitioning ADAPT from a prototype to an enterprise-scale platform,” he said. “We’re rebuilding it to scale up to support more users and more projects.”

Designing at the speed of sunlight

One of the clearest examples of ADAPT in action is in solar energy. Solar projects use large groups of solar panels to generate clean power and often span thousands of acres. Before construction begins, Kiewit teams must decide where each panel and the metal racks they sit on go. These placement plans, called layouts, serve as blueprints to make sure every panel fits correctly and efficiently.

These layouts are complex and time-consuming. Todd Eiter, Kiewit’s director of solar engineering and a key leader in ADAPT’s development, compared it to solving a large geometry puzzle.

“If you ask designers to create a solar layout, you’ll get different approaches since there are multiple ways to tackle it,” he said.

Before ADAPT, generating even one layout could take days or weeks, making it tough to stay competitive in a four-week bid cycle.

“Now we get multiple layouts within the first few days of an estimate kickoff, with our standards, constructability and quantities built in,” Eiter said.

Making that kind of speed and precision possible required innovative work behind the scenes — and that’s where Meghan Kelley and her team come in.

Kelley is a developer on the ADAPT team where she has led solar-related development since 2021. She designed the layout algorithm that powers today’s solar automation, which tests different metal rack configurations. Thanks to her team’s work, layouts that once took days now take about an hour.

“If something doesn’t fit quite right, they can tweak a few numbers and get a new version an hour later,” Kelley said. “It helps them get a better-quality estimate at the end of the day.”

Like KADE, ADAPT handles the time-consuming parts, giving teams more time to focus on higher-value work instead of repetitive tasks.

Moving dirt with data

One of the toughest jobs on any large construction site is planning how to move dirt efficiently. Before any building begins, crews must shift massive amounts of soil from one place to another. This process, called mass flow, can be expensive and time-consuming if not planned correctly.

Corey Wollen, a department manager at Kiewit Infrastructure Co., said those plans used to take months.

“To perform a mass flow, we had two people working on it full time for months,” Wollen said. “With ADAPT’s algorithm, you put all the inputs in and it runs in a matter of minutes to an hour on a big job.”

Wollen was an early adopter of ADAPT and helped shape its development by sharing jobsite challenges. The software analyzes variables like distance, soil type, trucking and equipment costs to find the most efficient and affordable way to move earth.

“All these variables make it challenging,” he said. “You can imagine there’s only so much someone can do in their head to analyze all of this. ADAPT gives us an output that’s optimized for the lowest cost.”

Wollen saw ADAPT’s power in action. He had a plan for moving dirt, but the software found a better one.

“I was blown away by that. Since then, I haven’t questioned in my mind that machines can do a better job than us when it comes to this.”

Wollen says ADAPT helps Kiewit save money, predict costs and avoid risks.

“I am proud to be a part of it. I can picture a world where many people use it and benefit from it,” Wollen said.

Together, KADE and ADAPT help teams move faster, think smarter and focus on the work that matters most. One optimizes trusted industry tools. The other was built from scratch to solve gaps no software could. What they have in common is how they came to life, driven by people inside Kiewit who knew there had to be a better way.

They’re more than tools. They’re proof of what’s possible when innovation starts from within.