In March 2021, the world’s eyes were on the Suez Canal where the Ever Given, one of the largest container ships in the world, was stuck in the vital passageway, blocking all traffic and delaying billions of dollars’ worth of cargo. News organizations followed the incident as crews worked to remove the container ship and restore critical trade routes between the U.S., Europe, Asia and the Middle East.

While the ship was finally freed after six days of emergency efforts, the impacts to the global supply chain lasted for months. One of the direct impacts: 20 containers destined for a Kiewit energy project were delayed more than two weeks because the ship was unable to pass through the canal due to the blockage. The Ever Given incident is one illustration of the risk involved in procurement and shipping, which is increasingly impacting the construction industry and Kiewit directly.

Over the past two years, the construction industry has been hit by what many have called the perfect storm: global supply chain issues, inflation, labor shortages and rising interest rates. For an industry that thrives on certainty and predictability — on schedule, cost and more — these challenges have been a significant disruptor, requiring contractors, suppliers and clients to find new ways of addressing material shortages, shipping times and logistics management.

In navigating this changing landscape, procuring the right materials within budget and delivering them to the project site at the right time has become more crucial than ever to ensuring project success. And in many ways, it has changed the way the industry will operate going forward.

“Procurement is the single biggest source of cost uncertainty right now for our clients,” said Andrew Gardner, president of Kiewit Supply Network (KSN). “A lot of people don’t realize that materials and shipping costs are generally 50% of the cost of the job.” He added, “Growing uncertainty around the availability of materials is driving pricing pressure up, and soon clients will find some projects aren’t viable unless contractors and suppliers deliver solutions.”

So what are those solutions? And how do projects manage risk in escalation, material shortages and shipping delays that are occurring across the entire industry?

“Procurement is an opportunity for Kiewit to be a comprehensive solutions provider for our clients, and it comes down to how we manage our supply network as a company,” said Gardner.

Kiewit’s supply network, as Gardner explains, is the sum of the company’s resources, relationships and processes that enable the delivery of goods and services for clients. This can range from highly technical equipment to run-of-the-mill office supplies. In total, Kiewit spends more than $7 billion annually to procure materials for projects.

Relationships and expertise

One of Kiewit’s core responsibilities has always been effectively managing materials for its locations. Prior to 2016, procurement services were split across Kiewit’s energy and infrastructure operations with teams focusing on those markets exclusively. In 2016, Kiewit centralized the data, resources and talent dedicated to procurement services to help make purchasing decisions across all markets and handle Kiewit’s supply chain more efficiently and proactively.

Kiewit’s dedicated workforce of procurement support staff has grown to over 380 people who provide procurement management tailored to the needs of each project. Within this group are subject matter experts experienced in import regulations, permit requirements for heavy haul transportation, logistics management, identifying and partnering with local, small and diverse businesses, and much more.

This team provides expertise to develop and maintain strong relationships with vendors, troubleshoot issues efficiently and share knowledge to support all of Kiewit’s projects across North America.

Having procurement experts available to help when needed has become crucial to project success during challenging times. Thomas Struchtemeyer, project manager for Kiewit Power Constructors Co., experienced this firsthand when he ran into delivery issues with equipment on the job.

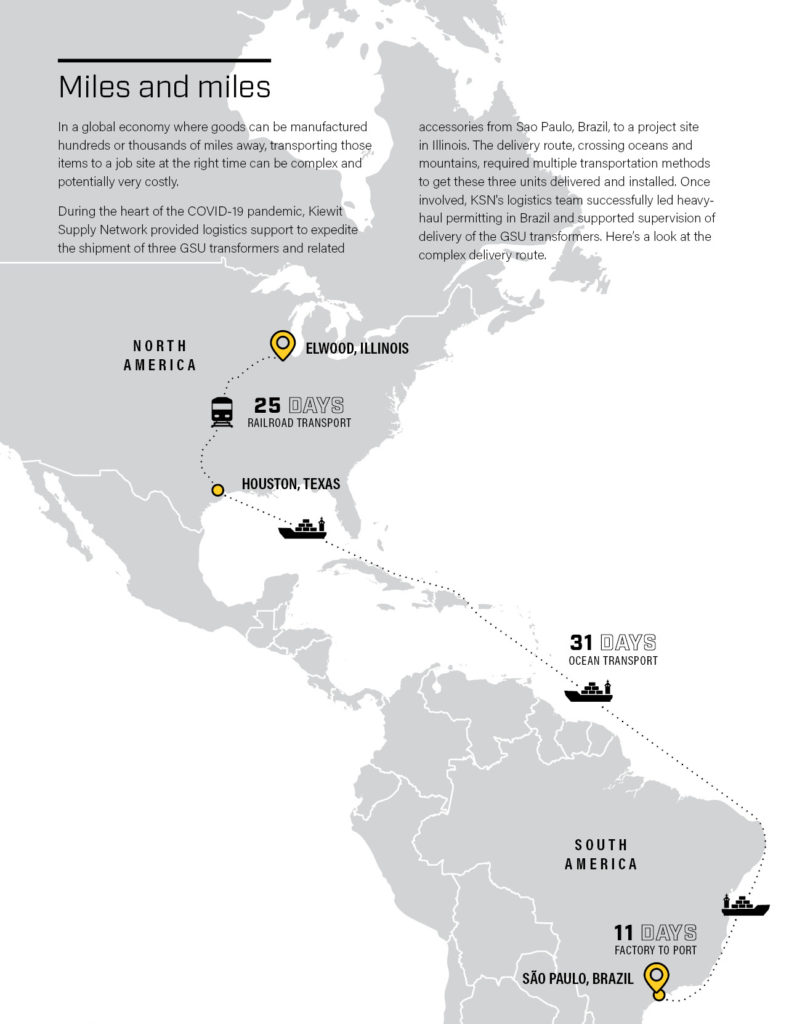

“We ran into an issue with the delivery of several generator step-up transformers (GSUs) that were delayed coming from South America,” he explained. In this scenario, this highly technical equipment could only be manufactured and procured from a limited number of experienced suppliers around the world.

On top of production delays, the supplier was having trouble coordinating heavy-haul transportation and obtaining the necessary permits to export the GSU units. The transformers were the largest units the supplier had exported from Brazil to date.

Receiving these units in a timely manner was imperative as the GSUs were “critical path,” meaning construction could not proceed until they were installed.

To troubleshoot the issue, Struchtemeyer contacted Gardner’s team for support. Once involved, KSN’s logistics team successfully led heavy-haul permitting in Brazil by providing “boots on the ground” support and supervising delivery of the GSU transformers.

“If Kiewit didn’t have this expertise internally, it would have been left to the project team to find solutions,” said Struchtemeyer. “That’s the beauty of having these subject matter experts at Kiewit. When I run into an issue, I call them, and they get the best people engaged to deliver solutions.”

Gardner says it’s challenges like these that show exactly what KSN experts are there for.

The generator step-up transformer pictured was the largest unit the supplier had exported from Brazil to date.

Solutions provider

Given the current environment, Kiewit has become more proactive in managing logistics and shipments, and helping suppliers and subcontractors with expediting delivery. With a strong and diverse supply base, the company has established strategic partnerships with vendors around the world to deliver projects. As with anything in construction and engineering, relationships are key.

“We understand that relationships are not only important with our clients but all the way through the supply chain,” said Gardner. “Understanding what our suppliers can provide and where, knowing where their fabrication facilities are, knowing what volumes they can manage, and stepping in to help manage the risk, helps our projects succeed.”

Kiewit has worked directly with suppliers to enhance design and equipment manufacturing. As one example, Kiewit worked with equipment suppliers for Heat Recovery Steam Generators (HRSG) and condenser equipment to optimize the design and shop fabrication to minimize the costs to assemble this equipment at the job site, ultimately saving the client money.

Gardner explained, “We work with organizations that can truly help us to get to the best value for our projects and bring the best value to our clients.”

While production and shipping delays are constant challenges within the construction industry, they have worsened since the outset of the pandemic. Material shortages impacting Kiewit’s projects include cement, copper, electrical steel and steel pipe.

Kiewit Project Manager Pegah Skarsgard has experienced numerous logistical and shipment challenges over the past two years. She explained, “Since the COVID-19 pandemic started, supply chain problems have been disrupting global shipping, which has resulted in shortage of containers and ultimately caused major schedule delays.”

Skarsgard credits KSN for helping her teams overcome these obstacles. “They have been able to provide insight to marine transit, port operations and alternate shipping options, and engage a number of industry contacts to gain access to ports whereas field personnel would not have been able to.”

Logistics and materials management has become a specialized skillset. Having people who understand global issues and know how to navigate disruption is not only helpful, but imperative to getting projects built in the current environment.

Risk management

Despite the unexpected challenges of the past few years, Kiewit has responded with solutions to ensure current projects stay on track and future projects are set up and managed for success. KSN uses a category management system that provides supply intelligence to help make purchasing decisions for frequently purchased items such as structural steel, pipe, valves, fittings and concrete.

Whether it’s hedging materials by buying for multiple jobs at once when possible, employing the category management program to inform purchasing decisions or working with long-time partners, Kiewit has developed an all-hands-on-deck approach to driving efficiencies.

While no one can predict future market dynamics, material shortages or inflation impacts, Kiewit has demonstrated it is prepared with the expertise in procurement to adapt and continue delivering successful projects.