Portland’s Columbia Boulevard Wastewater Treatment Plant receives major upgrades, increasing capacity and ensuring seismic resiliency.

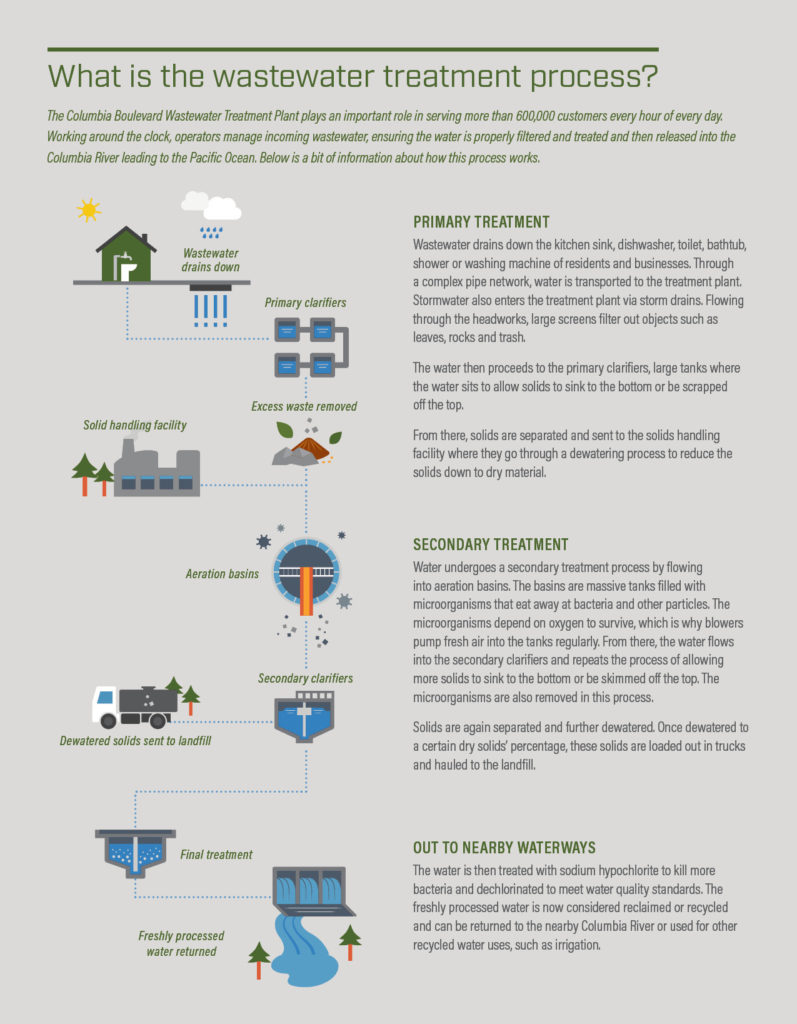

Operating 24 hours a day and 365 days a year, the Columbia Boulevard Wastewater Treatment Plant serves the growing city of Portland by protecting public health and ensuring clean water quality in the region’s rivers. The plant has a capacity of 450 million of gallons per day to handle waste and stormwater for the City of Portland, making it Oregon’s largest wastewater plant.

Since opening in 1952, the plant has made significant progress in ensuring sewage, agricultural and industrial waste is properly processed to maintain water quality in the nearby Willamette River and Columbia Slough. To improve operations of the plant and increase capacity to keep up with population growth, the City of Portland saw the need to add additional clarifiers and improve facilities, including solids handling and loadout systems as well as associated electrical and piping, which were growing old and needed to be updated or replaced.

Muriel Gueisssaz-Teufel, program manager for the City of Portland, explained, “The Columbia Boulevard WTP Secondary Treatment Expansion Project (STEP) is the most significant investment in Oregon’s largest treatment plant in 50 years. The project will allow us to meet our regulatory obligations with the Oregon Department of Environmental Quality, add significant operational and seismic resiliency to our treatment infrastructure and bring a significant part of our operations into the 21st century.”

Given the size, complexity and many stakeholders involved, the City of Portland chose a Construction Manager/General Contractor (CMGC) approach to manage the project. This allowed for early contractor engagement and a high-level of collaboration to complete the plant improvements by the deadline established by the Oregon Department of Environmental Quality.

Kiewit Infrastructure West Co. took the lead on this project by serving as the prime contractor, leveraging Kiewit’s capabilities in many areas including foundations, engineering, procurement and more, and pulling teams together from across the U.S. and Canada.

Upgrading an actively operating facility

Managing a project of this scale while keeping the facility in operation 24/7 is no small feat. Planning, coordination and a strategic sequencing of construction activities was critical to keeping this project tracking forward.

Kiewit became involved when design was 15% complete. Engaging closely with the client and owner advisor early on allowed the team to complete pre-construction work like the insertion of storage facilities, locker rooms, office space and the removal of aspects that would soon be remodeled in future phases of the job. This early involvement saved both time and cost.

As construction began, the Kiewit team simultaneously worked on demolishing existing structures, installing temporary building facilities and preparing the site for the construction of permanent facilities.

Water was only shut off on rare occasions and only for short periods of time for major activities; Otherwise, plant operations continued around the clock. Project Engineer Jason Regier explained: “The only way to shut off water to the plant is through combined sewer overflow tunnels (CSOs), which can close the gates that let water into the treatment plant for a short period of time until the tunnels fill up. However, there’s only eight hours’ worth of storage.”

Operating within these constraints, the team completed site updates including preparing the installation of new solids processing facilities, relocating critical utilities and control centers, making ground improvements and improving seismic resiliency across the plant.

Ground improvements completed by the foundation team included deep soil mixing and jet grouting to ensure all new structures could meet updated seismic standards and remain stabilized in the event of an earthquake. These ground improvement measures were critical to the success of the job.

Ground improvement techniques, such as deep soil mixing and jet grouting, prepared the soil to ensure new structures were stabilized and met updated seismic standards in the event of an earthquake.

Kiewit Engineering Group Inc. designed a SOE compression ring with reinforced interlocking secant piles to assist with seismic resiliency.

The project team completed select demolition activities on parts of the project that were to be replaced.

Saving time and cost

One key process improvement on the project was the implementation of the Decision Action Resolution Team (DART) log process, which drove the value engineering discussion and resulted in significant cost savings.

The DART Log served as the project database for new concepts to be proposed and reviewed by stakeholders to benefit the overall job. The log provided a systematic approach to value engineering so collaborative ideas could be tracked and acted upon. This included suggestions on items such as design alternatives and changes to scope or constructability in multiple disciplines including electrical, architectural, civil and structures work.

Construction Manager Eric Johanson said, “The DART log is an example of how the CMGC model is supposed to work, where Kiewit is engaged as an industry expert to help with the design phase and project constructability. Ultimately, we came up with ideas to make the project safer to build and in a way that is less costly with less risk and schedule impact.”

The Columbia Boulevard DART Log had over 90 accepted ideas and has saved over $111 million so far. In the category of seismic resiliency, there was over $9 million savings in approved and implemented DART suggestions.

Gueisssaz-Teufel added, “Kiewit has been particularly effective in bringing up value engineering options other team members, including the City, hadn’t thought about.”

Because of the overarching success of the DART log’s usage on this project, Kiewit will continue to use the log on other alternative delivery projects.

Building a diverse team

One element that encouraged the development of value engineering ideas was having a project-wide focus on teamwork, collaboration and diversity efforts. Diversity was a priority for the City of Portland early on. The CMGC method was chosen in part because of the opportunities it provided for increasing equity and diversity on the project team. This included contracting with locally certified businesses and apprentice programs for women and people of color in the construction phase.

“Increasing construction contracting and workforce diversity is extremely important for the City, especially at this scale of a project,” said Gueisssaz-Teufel. “We were able to keep a lot of contractors and apprentices working through the pandemic, where millions have gone to disadvantaged, minority, women-owned, emerging, service-disabled business enterprises while providing training opportunities to minority and women apprentices.”

The Community Benefits Agreement (CBA) established by the City of Portland outlined goals for the small business workforce and apprenticeship percentages on the job. Kiewit continues to far exceed the apprenticeship, minority and female workforce goals on the job.

The team’s focus on achieving and exceeding the CBA goals on the Columbia Boulevard Plant has turned the project into a model job for the City of Portland, illustrating how these goals bring value to the project.

“On the team we have people from all walks of life and that has brought a lot of good perspective and good ideas forward on the project,” said Johanson. “We’ve rolled out many trainings on respect, inclusion, equity and building a harassment-free culture, which has helped make this project a positive place to work. When people feel heard and included, they want to come to work and perform at their best and that’s been critical to our success.”

As a result of the diversity efforts and achievements on this job, Kiewit was nominated by the Professional Business Development Group and recognized by the Oregon Daily Journal of Commerce as a “Building Diversity 2022 Honoree”.

On track for success

With a diverse project team and consistent follow-through on the project plan, the Columbia Boulevard Wastewater Treatment Plant expansion is on schedule to add the additional facilities and complete upgrades by December 2025. Combining the values of all the various project phases, this project will exceed $500 million and will be one of the largest wastewater treatment plants that Kiewit has constructed to date.

Once complete, these upgrades will go a long way toward ensuring the Columbia Boulevard Wastewater Treatment Plant can continue performing the essential services of treating and processing wastewater for many years to come.