The historical landmark that connects the Lincoln Memorial and Arlington National Cemetery is getting new life, thanks to Kiewit’s innovative engineering and meticulous preservation.

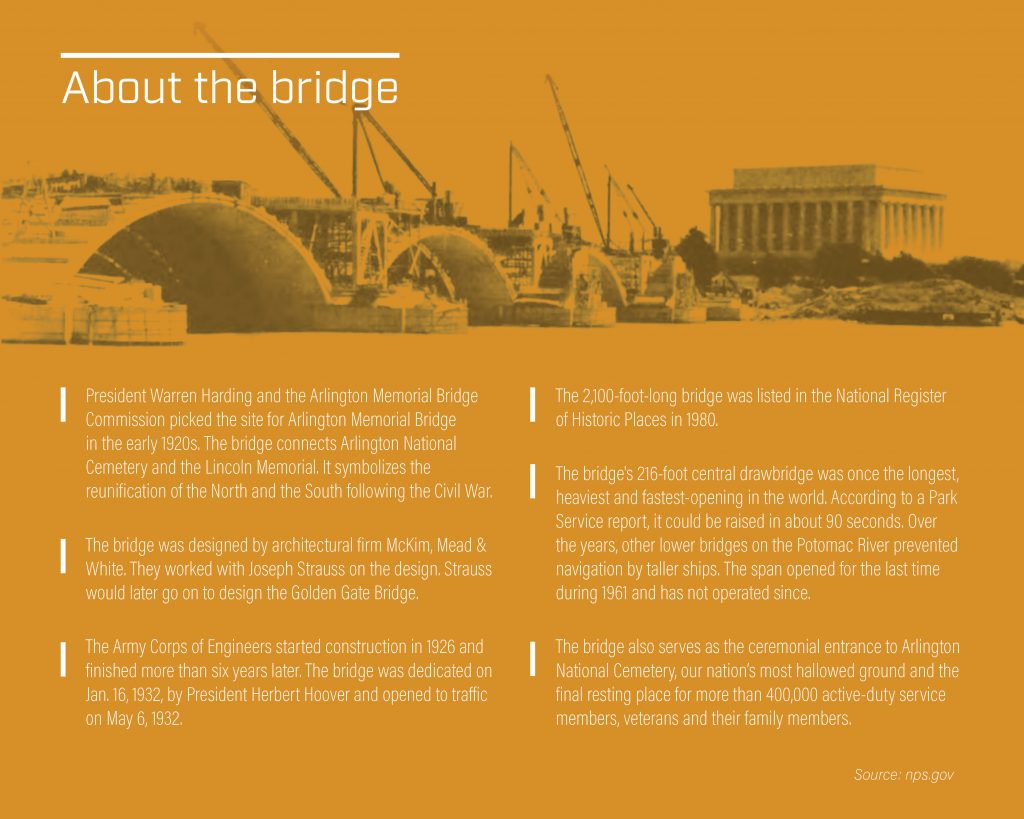

The Arlington Memorial Bridge in Washington, D.C., has seen a lot in its nearly 90-year history.

The iconic neoclassical structure is a symbolic post-Civil War connection between North and South.

It’s carried the bodies of President John F. Kennedy and Senator Robert Kennedy over the Potomac River to their final resting places in Arlington National Cemetery.

One of seven vehicular bridges connecting the District of Columbia and Virginia, it’s been responsible for delivering about 68,000 vehicles — as well as thousands of cyclists and pedestrians — to their destinations every day.

The stress of traffic, weather and age has taken its toll on the historical monument. Without a complete rehabilitation, travel on the bridge would compromise users’ safety and cause further damage.

In the years since it opened as a tribute to our nation’s military on Jan. 16, 1932, the structure has never been completely cleaned and repaired.

In 2018, the National Park Service took action to change that.

A doubly challenging job

Kiewit Infrastructure Co. won the bid for a contract that includes repairing the concrete arches and stone facades on the 10 approach spans, replacing the bascule span’s steel superstructure, reconstructing the bridge deck and sidewalks, and resurfacing all travel lanes.

With a compressed timeline, the team had a doubly challenging job: Preserve the historical integrity of the bridge and create engineering solutions to make sure it would be structurally sound for another 75 years.

Under the direction of the Federal Highway Administration, along with the National Park Service, Kiewit would make its own kind of history with some first-ever innovations.

The bulk of the work began in October 2018, but detailed planning, procurement and a lot of brainstorming started six months before that.

The process included creating a menu of options for the client to choose from.

“Often, these options had to go through several agencies for approval,” said Project Manager Donnie Arant.

“Every party had something that was important to them, so by giving them ways to pick and choose the pieces they wanted, we could come up with a collaborative solution.”

Throughout the planning process, Kiewit strived to strike a balance between preserving the original materials and suggesting the highest-quality products to extend the life of the bridge.

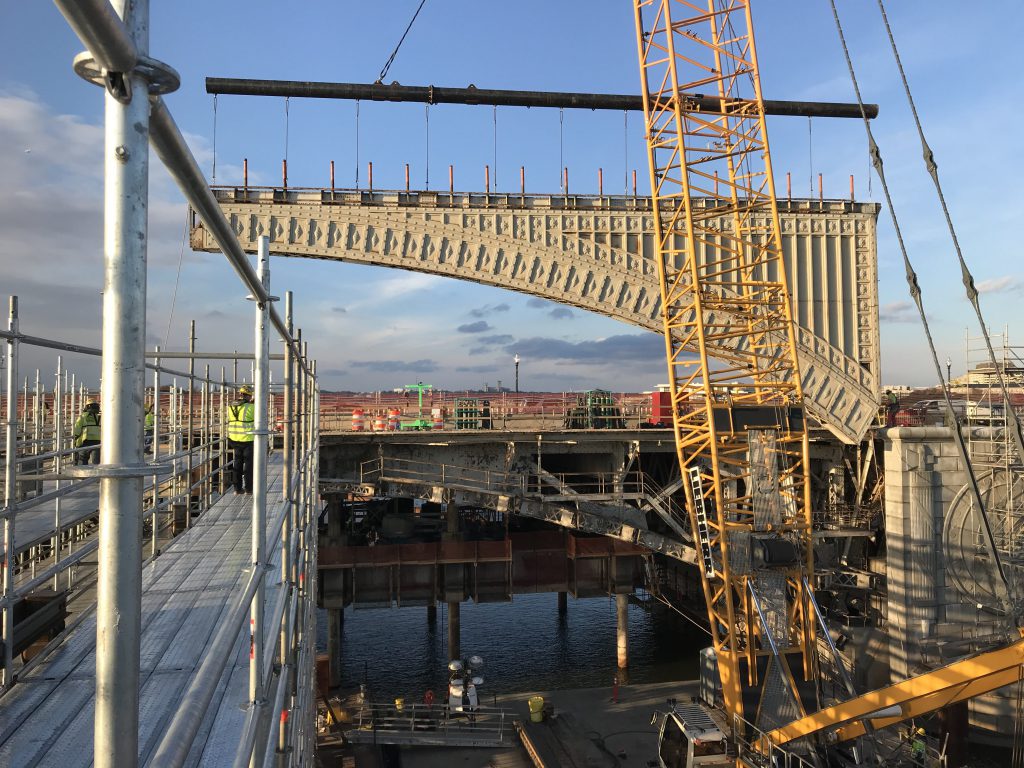

Kiewit removed the existing historic fascia with a custom picking device to refurbish it to its original condition.

Each piece of the bridge railings had to be meticulously cataloged, removed, repaired, cleaned and reinstalled in the same exact location.

Pride on the job

To put together a craft workforce with the experience and specific skill sets needed for this project, Construction Manager Luke Silvus reached out to his local contacts.

“I called the business agents for the unions in different disciplines, and I had them send out a couple of their key folks. I met with those guys and interviewed them. And then I had them recommend the best people for the job.”

Once the team was assembled, the momentum “spread like wildfire,” Silvus said.

“At the monthly safety meetings, we would have some of our craft come up and say a few things about what they were building.

“We’ve built such high morale on the job. A lot of it has to do with the pride that people are feeling, working here.”

Keeping the patina

Maintaining the original look of the bridge, and wherever possible the original materials and finishes, has been a top priority.

“The standards set by the Secretary of the Interior dictate that a light patina is part of the nature of an historical structure,” Arant said. “The project owner wanted to make sure we took a lot of care in how each element was restored in order to maintain the original character.”

The catch basin grates along the curb line, for example, needed to look exactly the same. They’re not industry standard anymore, so the team made custom molds to recreate them exactly as they originally were.

Preserving the bollards — the original pop-up protective posts on the drawbridge that’s no longer in use — was also important to the project owner.

“The posts were in conflict with one of our walls we had to build,” said Arant. “The client said, ‘Please do everything you can to retain them; they’re an important historical piece.’

So we actually came up with some engineering to not have to remove them.”

Recreating the original

To allow for restoration of the drawbridge façade, the team built a custom cradle on a barge. Handling the piece as a complete unit was a much preferable option compared with removing every piece of detail and reassembling it.

Kiewit also worked with subcontractor Lorton Stone to inventory the thousands of balustrades, carefully clean them, and replace them in the

exact same location.

“The client wanted them pointed in the correct direction that they were originally,” Arant said. “So if a certain railing had a certain portion of it pointing north, that had to be placed pointing north.”

‘The job of a lifetime’

With the south side of the bridge substantially complete, attention now moves to the north side where the team will perform the same tasks. The entire job is scheduled for completion by spring 2021.

The team says memories of this project will stay with them for a long time.

“These clients have been true partners, and I would consider them true friends,” Arant said. “Our team has the kind of chemistry that just doesn’t happen on every project. It’s one of the best I’ve ever worked with.”

“There have been half a dozen times on this job where we look at ourselves and say, ‘This is just amazing that we’re doing all of these first-ever kind of things,’” Senior Structural Engineer Dave Lamoureux noted. “The project is a really cool experience.”

“This is the job of a lifetime,” added Silvus. “Every morning we get up, and we come to work and get to watch the sun rise over the Lincoln Memorial and the Washington Monument. It’s unreal.”