Nuclear’s next era is here. Kiewit is already at work.

After decades of paused growth, the nuclear industry is experiencing a resurgence. Rising energy demands, the rapid expansion of data centers and advancements in reactor technology have reignited interest in nuclear power as a carbon-free, baseload energy source. Additionally, the U.S. Department of Energy (DOE) is ramping up efforts to modernize the country’s nuclear strategic security infrastructure. As momentum builds, many companies are aggressively pursuing these opportunities.

For Kiewit, this isn’t a new chapter — it’s the continuation of a nuclear story more than 70 years in the making.

“We’ve been preparing for what we believe is the next wave of the nuclear market,” said Mike Rinehart, President of Kiewit Nuclear Solutions Co. (KNS). “By securing necessary licenses, building a world-class team and delivering on major nuclear infrastructure projects, we’re ready to provide solutions for this complex federal and commercial nuclear market as it accelerates.”

Building on legacy

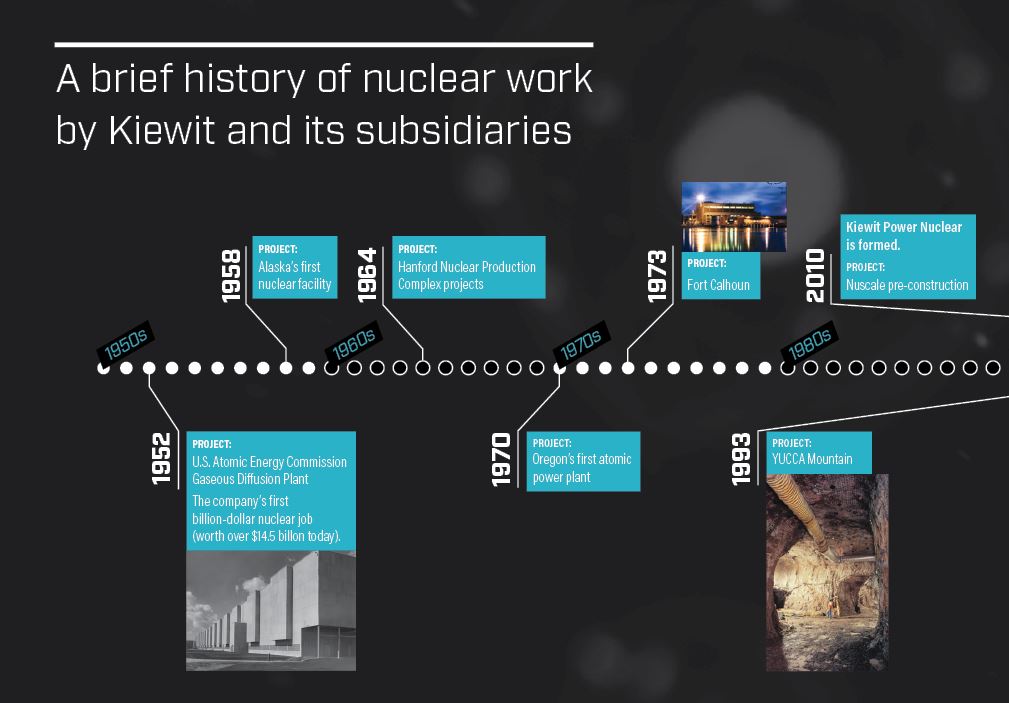

Kiewit’s involvement in nuclear infrastructure dates back to 1952, when the company was awarded a $1 billion gaseous diffusion uranium enrichment contract for the U.S. Atomic Energy Commission at the Portsmouth facility in Ohio. That groundbreaking project employed over 20,000 craft employees, bolstered the nation’s nuclear security and laid a foundation for Kiewit’s enduring presence in the industry.

In the decades that followed, Kiewit delivered hundreds of commercial and federal nuclear projects, including Alaska’s first nuclear facility; a 455-megawatt nuclear plant in Fort Calhoun, Nebraska; and the tunneling of Yucca Mountain in Nevada.

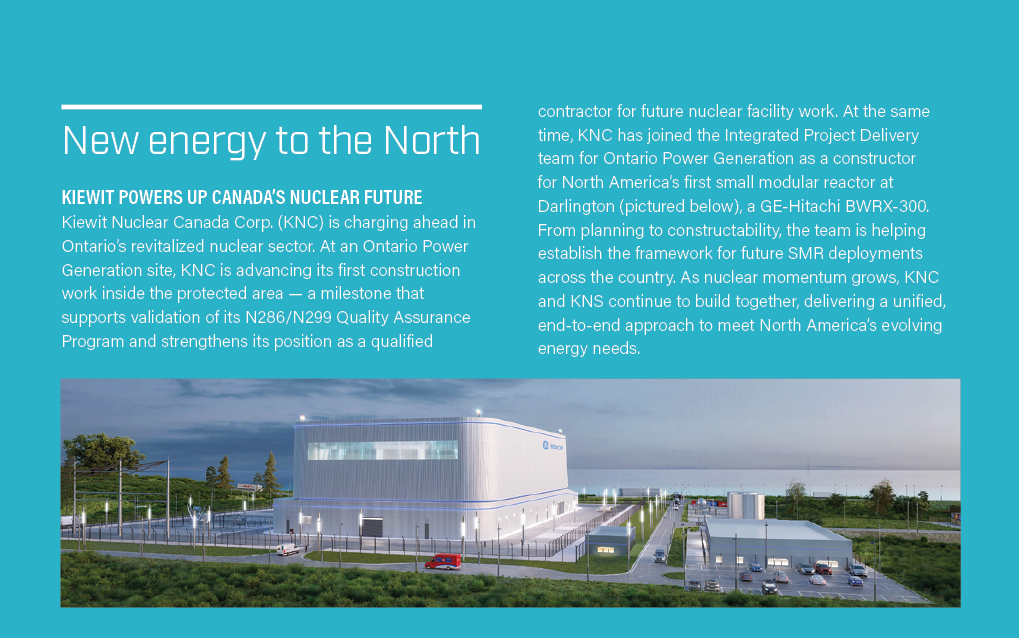

In 2010, the company established Kiewit Power Nuclear under Kiewit Power Constructors Co., reinforcing the company’s commitment to the nuclear market. Later, in 2017, it founded Kiewit Nuclear Canada Corp. (KNC) — positioning itself for opportunities across North America.

While commercial nuclear development slowed during this time due to competitive natural gas prices, DOE project deferment and post-Fukushima regulations, Kiewit remained engaged. The company closely tracked market signals and federal direction — ready to reenter the market. By the time federal funding returned, Kiewit was already in motion.

Valued at more than $14.5 billion today, Kiewit's first billion-dollar nuclear project at the U.S. Atomic Energy Commission's Portsmouth facility in Ohio increased the country’s enriched uranium production, helping maintain its nuclear security.

Fortress of fuel

Since 2020, Kiewit has served as a key subcontractor on the Spent Fuel Handling Project (SFHP) at Idaho National Laboratory (INL). Partnering with Amentum and Fluor Marine Propulsion, the team is building a next-generation facility to safely process, package and transfer spent nuclear fuel from the Navy’s nuclear-powered submarines and aircraft carriers, which account for roughly 40 percent of the fleet.

The scope is massive. The project involves the acquisition, fabrication, painting, coating, shipping, handling and erection of 17,000 tons of nuclear-quality steel — the equivalent of two-and-a-half Eiffel Towers — forming the framework for the high-bay processing facility and adjoining support areas.

Because the project is governed by Nuclear Quality Assurance Level 1 (NQA-1) standards, Kiewit is implementing a strict quality assurance program.

“It’s a brand-new facility, so there’s no existing radioactivity to worry about,” said Jerry Ice, vice president of nuclear quality. “But this project is quality Level 1. Any failure of structures, systems or components could impact people and the environment. That’s why our procedures and work packages are strict and must be followed exactly. There’s no room for interpretation. If something doesn’t align with the process, we stop work, engage leadership and find the right path forward.”

SFHP is one of several jobs Kiewit has worked on for INL. Project Manager Ben Wiles says that maintaining engagement has been key in supporting INL’s multi-billion-dollar project pipeline as a preferred contractor of choice. He says it will remain essential as part of Kiewit’s long-term success strategy, including on a recently awarded INL contract worth more than $1.1 billion for additional mechanical, electrical and HVAC work at the facility.

“We try to instill a marathon mentality,” he said. “We’ve created a team culture that prioritizes training and a long-term vision, making sure our workforce maintains the same level of engagement and criticality so we can deliver consistency to the client.”

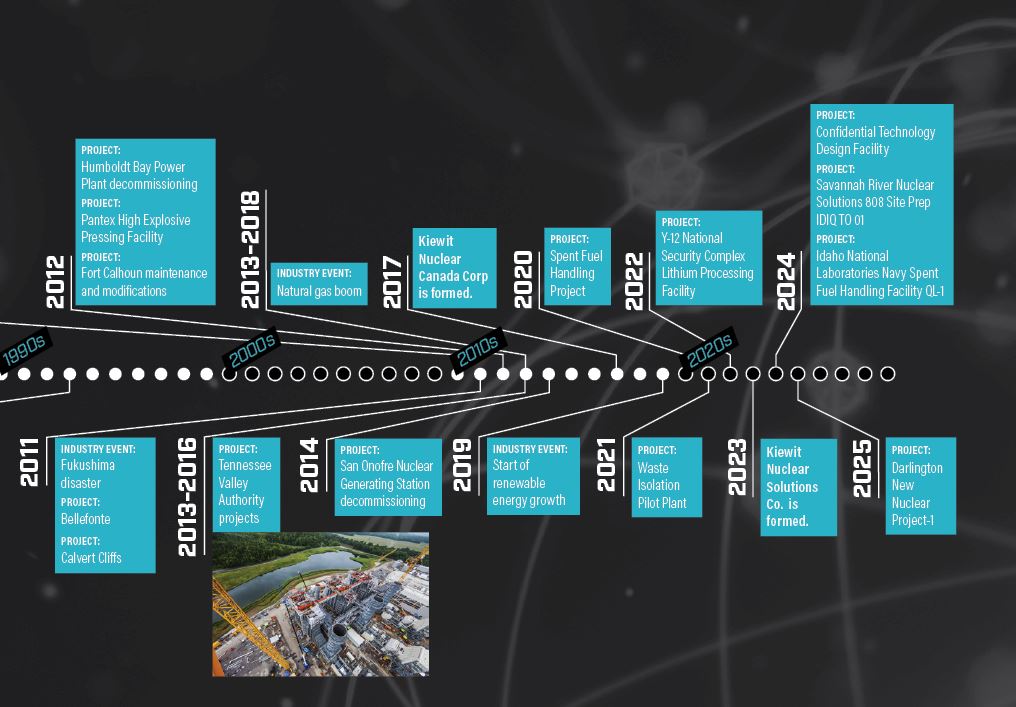

Wiles’ emphasis on consistent delivery is evident across Kiewit’s nuclear portfolio. In 2021, that mindset was put to the test on a high-profile recovery in New Mexico.

The south half of the west wall takes shape at the Spent Fuel Handling Facility. Once complete, the facility will include 17,000 tons of nuclear quality structural steel.

A 125-foot-tall exhaust stack rises above the Waste Isolation Pilot Plant (WIPP) in southeastern New Mexico, part of a new ventilation system supporting safer underground operations.

To ensure safe integration of the new ventilation system into daily operations, it has undergone rigorous testing.

Precision under pressure

When Kiewit was asked to recover the Waste Isolation Pilot Plant (WIPP) in 2021, the project had already faced significant delays. Speed and precision would prove crucial to getting the job back on track.

Located 2,150 feet underground in an ancient salt bed near Carlsbad, New Mexico, WIPP is the nation’s only deep geological repository for transuranic (TRU) nuclear waste, byproducts of U.S. national defense programs, and this essential storage facility was in desperate need of a new ventilation system.

To fast-track recovery, Kiewit subsidiary, TIC – The Industrial Co., activated its established Nuclear Quality Assurance (NQA-1) program and made sure materials and equipment met exact nuclear quality standards. The team then completed construction of the new safety-significant confinement ventilation system (SSCVS), designed to more than triple underground airflow. This new system integrates a high-efficiency particulate air (HEPA) filtration system, enabling simultaneous mining, waste placement, maintenance and scientific research — capabilities that were previously constrained due to limited ventilation.

“We self-performed the majority of the project, from dirt work, concrete, erecting precast, electrical and instrumentation, and transitioning to erecting ductwork and heavy structural steel,” said Brian Mailhot, project manager at WIPP.

“What was apparent from the get-go was our ability to mobilize resources — people, equipment, materials — whatever is needed,” he added. “Being able to bring that expertise within one organization is a huge advantage.”

The DOE reports that, despite initial setbacks, the project was completed under budget and ahead of schedule.

That outcome isn’t just a measure of technical success — it’s a reflection of Kiewit’s ability to deliver under pressure, in some of construction and engineering’s most demanding environments.

From legacy to leadership

With momentum building across the nuclear industry, the path ahead is full of opportunity. With rigorous attention to safety, regulatory compliance and quality control embedded in every project, Kiewit is positioned to lead in this rapidly evolving market.

The company is currently pursuing more than 20 major commercial nuclear projects — from uranium enrichment to large-scale reactors like the AP1000, as well as small modular reactors, including Gen IV technologies. By remaining technology agnostic, Kiewit ensures it can match the right solutions to each project, bringing a “best-athlete” approach to this growing sector.

While the commercial market continues to mature, the DOE budget remains at record levels, focused on modernizing production infrastructure across the country. Kiewit is positioned for a growing role across the DOE and National Nuclear Security Administration complex.

More than 70 years after its first nuclear project, Kiewit continues to expand its role in the industry. That role is now carried forward by KNS, which succeeded Kiewit Power Nuclear in 2023, joining Kiewit Nuclear Canada Corp. to form the company’s dedicated nuclear entities across North America. Together, they reflect Kiewit’s unified, end-to-end approach to nuclear delivery — shaped by the company’s legacy of execution and trust from its clients to deliver when it matters most.

Aaron Love, who leads a number of key KNS projects, said that trust is something the company plans to keep earning.

“When you have a client come in and they’re in dire need to finish something, and they put that ‘bat signal’ up to get qualified contractors to do what they do best — we’ve been called and we’ve delivered. That’s always a good story, and it’s one we want to keep telling, project after project.