How many people does it take to change a light bulb? The answer usually depends on who’s telling the joke.

What about the number of people it takes to produce the electricity to power the light bulb?

That answer: a lot — and the skill and coordination required to make it happen is no laughing matter.

At the site of the Tennessee Valley Authority’s (TVA) new Paradise Combined Cycle Plant, construction is in the homestretch. Thanks to the teamwork of countless individuals, cleaner, more efficient power is set to reach homes and businesses in 2017.

Powerful, positive relationship

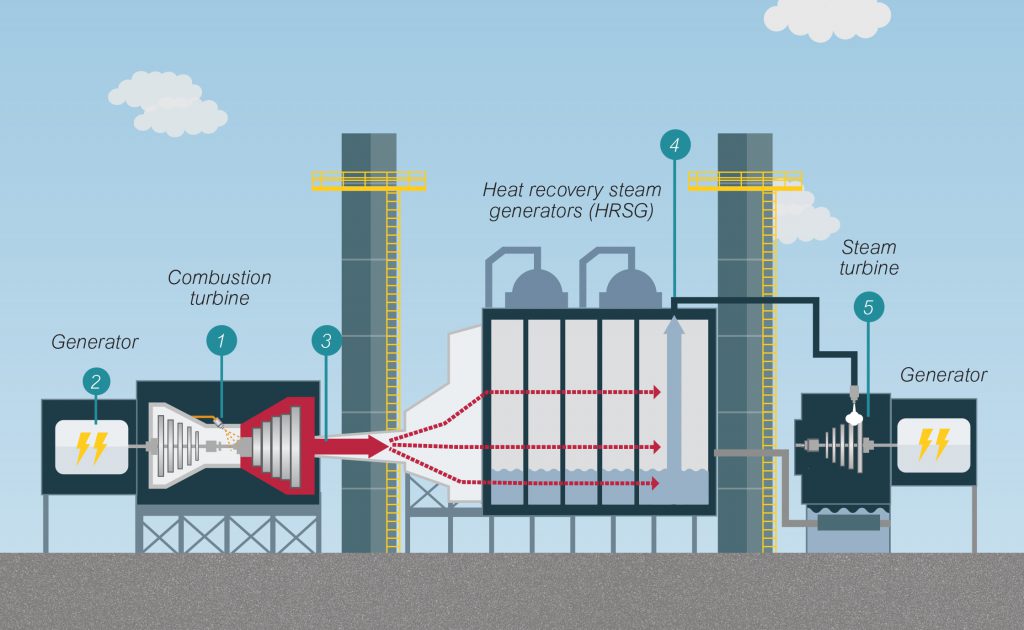

The 1,100-megawatt Paradise Combined Cycle Plant is being built next to TVA’s Paradise Fossil Plant near Drakesboro, Kentucky. The first two of three coal-fired units at the fossil plant came online in 1963 and will be retired once the combined cycle plant is up and running.

This is the second time that TVA has built a combined cycle plant adjacent to — and in complete or partial replacement of — an existing fossil plant as part of its commitment to produce safer, cleaner, more efficient energy. The first instance, the John Sevier Combined Cycle Plant, is also where TVA, which is the nation’s largest government-owned power provider, first worked with Kiewit.

Kiewit completed the construction scope of work on John Sevier in 2012, while another organization coordinated engineering and procurement. Due in large part to a positive experience there, TVA awarded Kiewit an engineering, procurement and construction (EPC) contract for the Paradise job. It was the first time TVA issued an EPC contract for a new power plant to Kiewit.

Roger Waldrep, general manager of TVA major projects, said the John Sevier job “laid the groundwork for our relationship.” But while TVA knew Kiewit could handle construction, the team would also have to prove it could design and engineer a power plant.

A culture of listening and sharing

When the EPC contract was awarded in June 2014, Kiewit set out to make TVA raving fans of its entire power organization.

“It was crucial for us to earn TVA’s trust in our engineering and procurement teams,” Kiewit EPC Project Manager Chris Turnbull said. “They had confidence that we could build the work, but proving to them that we could execute well with engineering and procurement was a top priority for us at the beginning of the project.”

Achieving that goal would rely on collaboration between all project stakeholders, beginning with approximately eight months of engineering and procurement in Lenexa, Kansas, where Kiewit’s power group is based.

“Our construction engineers and superintendents were embedded with our engineering team from the start,” said Turnbull. “We were all on the same floor and in conference rooms working together. You couldn’t tell who was a construction person and who was an engineering person.”

Completing a design that could be built successfully in the field was dependent on everyone letting the other know what they’d need to succeed.

“We started our design working to support what we called Glenn’s ‘Blue Sky’ schedule,” said Kiewit Engineering Project Manager Dan Langstraat. “Essentially this was how the construction team, led by Glenn Miltenberger, would build the power plant if there were no restraints from engineering or procurement.”

Procurement played an important role in developing the engineering plan.

“Getting all engineered equipment purchased is a really important part of setting the engineering team up for success,” said Langstraat. “We need vendor information from suppliers to execute design. On Paradise, all equipment was under contract within six months after the EPC contract award. This aggressive schedule has become a best practice in our organization.”

As designers encountered challenges that would alter the construction schedule, Constructability Manager Steve Packard and team helped find solutions that worked for engineering and construction.

“The constructability team makes sure information flows from all parties to get the best results for the project,” said Packard. “It’s really about how our organization integrates all phases of a job and establishes a culture of listening and sharing to ensure it’s successful. We’ve built great relationships with major vendors and clients, and have kept the construction minds connected to engineering.”

A well-structured team

In January 2015, the first construction crews arrived in Drakesboro. Strong ties between all parts of the team proved beneficial as construction started and engineering continued.

“Our relationship with engineering had everything to do with how well we got out of the ground,” said Miltenberger, who was the project manager at John Sevier. “We respected and listened to each other and made good decisions in Lenexa, which has helped us here in the field. Our engineering team has been very responsive when we’ve needed them.”

Changes made to engineering were done with the safety of those building the work in mind. It became more personal once people were on-site.

“We got started on day one building our safety culture,” said Safety Manager Dave Hinz. “If you have a strong culture and clear expectations, it’s much easier to get people to buy in as your craft numbers grow toward their peak.”

As numbers swelled to almost 140 staff — including on-site design engineers — and 620 craft and subcontractors, earlier procurement activities and certainty of delivery dates paved the way for completing major construction milestones as scheduled.

“Days go by fast out here, but we’ve always been where we needed to be with our schedule, and we owe that to our team structure,” said Construction Manager Chuck Davenport. “From design and constructability in Lenexa, to when we broke ground, to today as we approach completion, we’ve had a well-structured team. That’s been the key to completing things as planned.”

Turnbull said it’s hard to overstate the impact all of the early work has had on construction.

“On an EPC project the first phases are so important,” said Turnbull. “If these jobs don’t start well, they typically don’t end well in the field. You can’t underestimate how much effort you have to put in at the beginning of the project.”

He compared it to a simple concept.

“It’s like trying to shove a giant boulder down a hill,” he said. “In the beginning you need everybody pushing really hard and all in the same direction just to get the thing to start rolling. Once it starts picking up momentum, you better hope you’ve got it pointed in the right direction because if you don’t, it’s very difficult or impossible to change direction. If you get the job designed and procured right, you set the construction team up to finish the job well.”

Rising to challenges

The construction team built on positive momentum and is headed toward an on-time and on-budget completion in early 2017. Turnbull, Miltenberger and other leaders praise staff and craft performance.

“We’re out here in a rural area where most people drive an hour to work each day and morale has always been strong,” said Miltenberger.

“Everyone has risen to challenges and continued to operate at a high level for close to two years,” said Turnbull. “Sustaining that can be incredibly difficult, but our team has done it.”

Project Engineer Mike Wilkie said the performance has led to several promotions.

“Every discipline has had an advancement or position change,” Wilkie said. “We know it’s important for everyone personally, and for the organization, for people to be able to advance in their career goals.”

Younger staff are quick to credit success back to leadership on the job.

“Management here is incredible,” said Field Engineer Chris Kephart. “They have a lot of experience in this type of work and were committed to having the right team. There’s great leadership on this job and it shows.”

Cleaner, safer, more efficient

Once the metaphorical boulder gets to the bottom of the hill, people in the region might not know all that went into the cleaner, safer and more efficient electricity powering their light bulbs, appliances, electronics and more. But building Paradise is an experience Kiewit and TVA won’t soon forget, especially as they look to replicate that success on TVA’s Allen Combined Cycle Plant in Memphis, Tennessee, which Kiewit is also building under an EPC contract.

“When it’s complete, Paradise will be the most efficient gas plant in our fleet,” Waldrep said. “We’re on track to deliver a good product ahead of schedule, and we’ve built a great relationship with Kiewit that we’re already leveraging at Allen.”

Turnbull again summed things up simply.

“This is absolutely the best job I’ve ever been a part of,” he said.