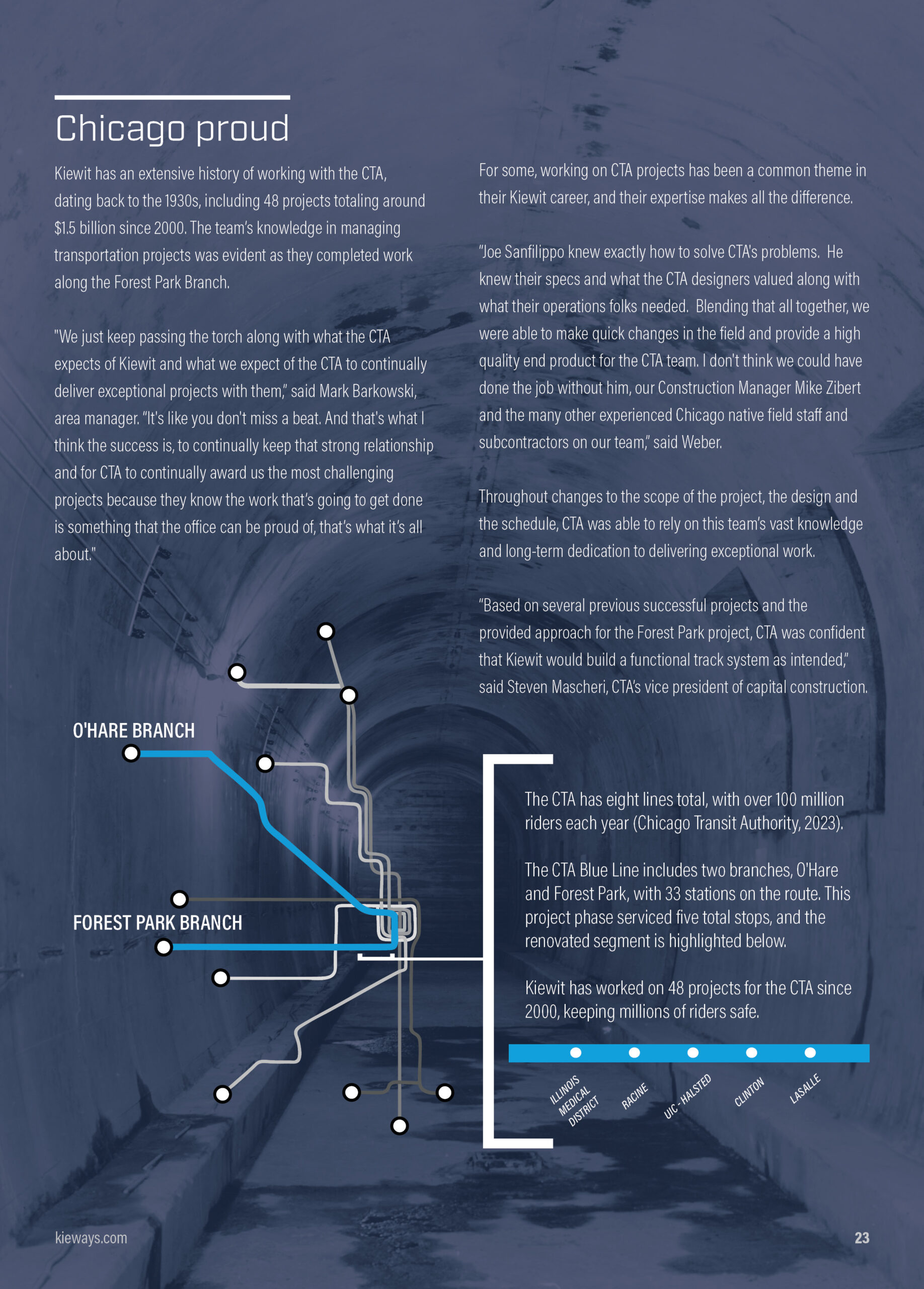

In the late 1950s, the original Forest Park Branch of Chicago’s elevated train system was constructed, establishing a vital link of the Blue Line to connect Chicago-O’Hare International Airport to downtown.

Due to its location in one of the lower-lying areas of the city, this area is prone to flooding. After six decades of transporting daily commuters, the wear and tear has resulted in the highest number of “slow zones” along any train line in the city.

Recognizing the need for a transformative solution, the Chicago Transit Authority (CTA) entrusted Kiewit Infrastructure Co. with the $105 million Forest Park Branch of the Blue Line reconstruction project, focusing on enhancing speed, safety and accessibility along a 1.5-mile stretch between the UIC-Halsted and Illinois Medical District stations.

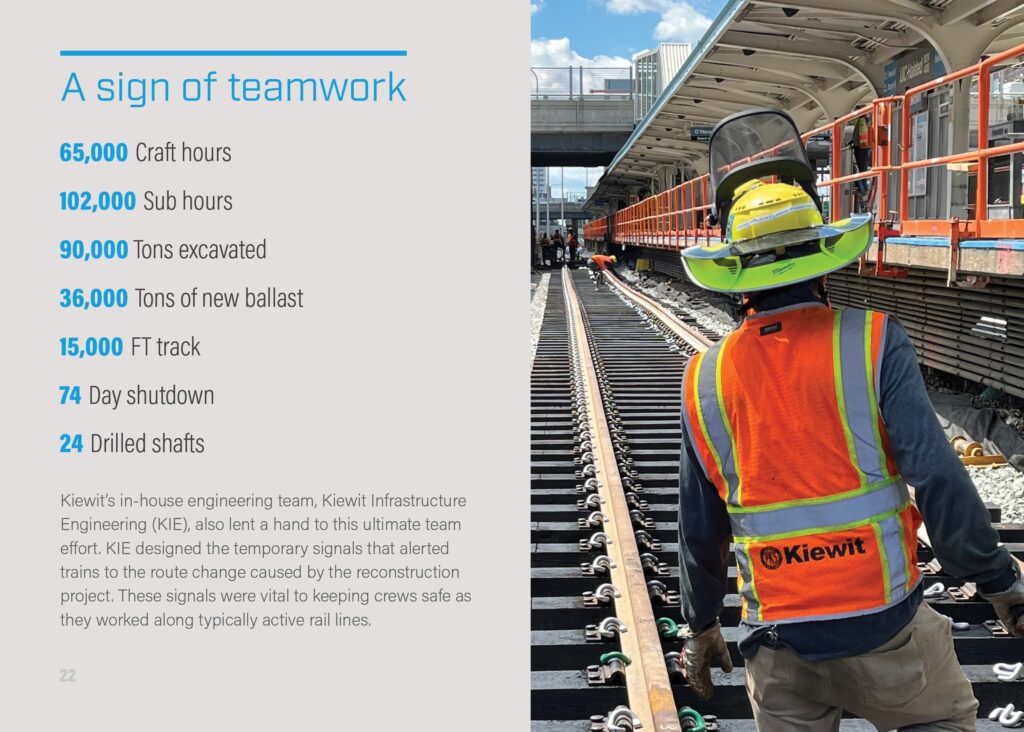

Over a swift 11-week period, in time to return service for the Chicago Marathon, the project team worked continuously, replacing rails, ties and ballast, and improving the track drainage system and traction power.

Accelerating at Halsted Station

When crews began work on the Blue Line, service between these stations was suspended and riders were transferred to bus shuttles to complete their trip. Due to the strain this shuttle service put on CTA’s resources, one month before the outage CTA requested that Kiewit expedite the work at the UIC-Halsted station, aiming for completion in 28 days — one month earlier than initially planned.

“We didn’t shy away from it. We priced it, talked to our key subcontractors and looked into what it would take,” said Blake Richards, senior project manager.

The timeline acceleration was a complete team effort. Kiewit teams pivoted their plans and worked alongside the design team and CTA to resequence work and increase resources.

“We had originally planned to have two main headings of people and equipment working along the rail line, and they would start at one end of the project and work their way to the other,” said Kayleigh Weber, project manager.

To deliver a portion of the project early, and still build the rest of the job on time, Kiewit added an additional heading, a set of equipment and crew. Collaboratively, CTA agreed to handle the tamping with their equipment, bypassing the delay associated with waiting for the scheduled delivery of Kiewit’s equipment, which was initially set to align with the original completion date.

By mid-August, the UIC-Halsted station was reopened to the public.

Regulatory Blocks

Long before the service outage began along the Blue Line, Kiewit teams were working to plan the work, procure materials, team up with vendors and subcontractors and obtain permits for the project.

“We worked very closely with the city, CTA and the designers to collaboratively make one team to get those permits done,” said Joe Sanfilippo, project manager.

Permits were required for the drainage work and to install drilled shafts — crucial foundation work — at the Morgan Street and Racine stations. Ideally, these permits would have been obtained before the outage, since that work could not begin without them.

“We planned on performing a lot of early work prior to the shutdown to level resources needed during the shutdown.” said Weber. “We didn’t get the required work permits from the client until the week before the shutdown, so we had a lot of acceleration, long hours and it put a lot of pressure on the team during the shutdown.”

The permit for drilling at the Morgan Street substation was obtained first, and even though it significantly resequenced the work, crews began drilling on that site the same day. However, the challenges kept coming.

Around-the-Clock Solutions

When the drilling began, it was discovered that the soil conditions were not as expected, meaning the ground was not amenable to the foundation design.

In order to support the new station and substation, the tip elevation of the drilled shafts was raised to land on a suitable soil layer. These solutions had to be vetted by numerous project partners before moving ahead to drilling. To facilitate this redesign, the CTA mobilized drill rigs and performed a new soil boring program on 12 hours’ notice.

In addition to the geotechnical issues, the team faced other unforeseen conditions underground. After excavating the site, the sub grade testing revealed low soil bearing capacity. To mitigate the issue, additional geotechnical membranes and fabric were added to reinforce all three miles of the trackbed.

“We had a large number of field design changes, a majority of which happened in that accelerated section for the Halsted station, so we had very limited time to get engineering answers,” said Weber. “But the CTA and their designers were really great partners.”

To keep work moving in the field, the team implemented a Field Change Notice, an expedited information request. “When we found problems in the field, our team and the CTA field inspectors took pictures and discussed the issues as they happened,” said Richards. “There was a very collaborative approach between not just the Kiewit team but also the owner and designer to solve problems in real time.”

Upon completion, about 15,000 feet of slow zones were removed, increasing this section’s travel time by two minutes. The project included the removal and reinstallation of about 100,000 tons of materials. Additionally, the Racine station, where Kiewit completed the foundation work, will receive key accessibility improvements such as an elevator.

In the end, Kiewit overcame project challenges, worked collaboratively with the CTA to resolve field changes, and provided solutions to finish the outage before the Chicago Marathon.

“The project is viewed as a success by meeting an aggressive schedule and complicated scope of work while minimizing disruption to our ridership and operations team,” said Mascheri. “This was attained by open and transparent communication with Kiewit and the project team followed by quality execution of the work.”