Big Bar Project tackles life-changing landslide in British Columbia

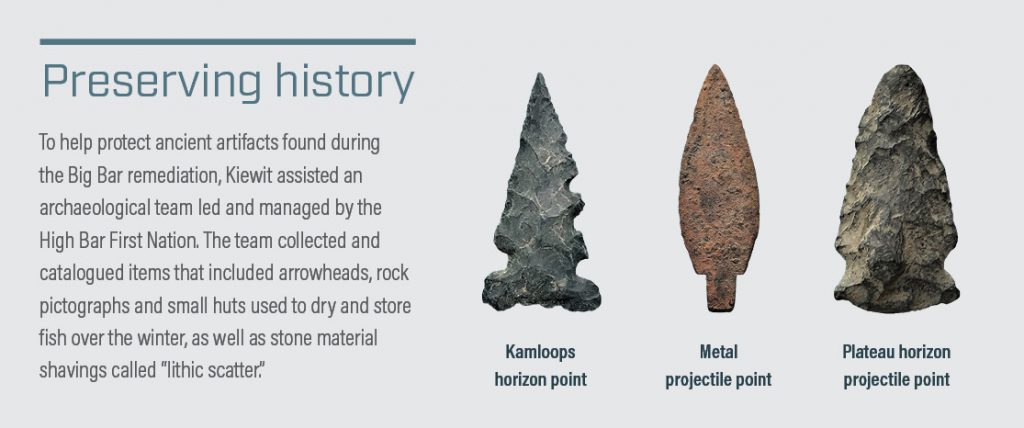

The migrating salmon that travel the Fraser River in British Columbia are crucial to the livelihood of commercial fishers and members of local First Nation communities who rely on these and other fish for food and as part of their cultures. A 2018 landslide brought fishing in one area to a standstill. Kiewit has been working to help restore the habitat and preserve the communities’ long-standing traditions.

About 365 kilometers (227 miles) into their spring 2019 migration up the Fraser River in British Columbia, the Early Stuart sockeye salmon were likely the first to notice a problem north of Lillooet. In construction terms, the road was closed.

The Stuart sockeye are the initial wave of salmon that travel the waterway every year, coming in from the Pacific Ocean near Vancouver on their long trip. Some will swim as many as 1,000 kilometers (620 miles).

But last year, at a remote part of the river near an area called Big Bar, these fish and those that followed encountered the effects of an event described by residents and experts as “devastating” and “disastrous.”

A dramatic sight

After a report of a suspected landslide was communicated to authorities in summer 2019, officials from the Department of Fisheries and Oceans (DFO) visited the site.

What they discovered was dramatic: About 110,000 cubic meters (143,875 cubic yards) of boulders the size of three-story, 3,000 square-foot houses and other debris had cut away a 125-meter (410-foot) cliff. The huge rocks tumbled into the river, significantly narrowing the water flow and creating a 5-meter-high (16-foot) waterfall.

Satellite imagery confirmed that the slide had occurred at least seven months before, in October or November of 2018.

To try to save some of the fish, approximately 30,000 were moved upriver by helicopter. Remarkably, an estimated 245,000 still managed to traverse the slide naturally.

The initial emergency response by the Canadian government and DFO transitioned to an ongoing project response by fall 2019.

Removing the rock, remediating the site

At the end of last year, Kiewit was awarded a contract by Public Works and Government Services Canada to perform extensive remediation of the site from January through March.

Completing work before the spring thaw — known as the freshet — and the subsequent rise in water levels was critical.

The scope of work not only included removing as much debris from the river as possible, but also building an 800-meter (2,625-foot) access road to transport a large fleet of heavy equipment, including five excavators ranging from 25 to 90 tons, excavator-mounted drills, 30-ton rock trucks and a telehandler. The job also required stabilizing the rock slope to make the area safe for crews to work at river level.

“Our plan meant we would spend a significant amount of time gaining access to the water — seven of the 10 weeks available to do the work,” said Project Manager Patrick Wilson.

The team faced a typically brutal Canadian winter, braving winds that gusted over 100 kilometers per hour (62 miles per hour) in the 700 meter (2,300 feet) deep canyon. Temperatures also weren’t kind: The first week on site in January, crews were met with temperatures that dipped to minus 40 C/F.

“The first week of mobilization was really tough before the weather stabilized a little bit,” Wilson said. “Nothing would start, nothing would work. The helicopter couldn’t run. The boats couldn’t get in the water because the ice was too thick.”

Carving the razorback

One of the biggest obstacles to building the road was punching through a rock structure that needed to be partially carved away in order to make the proper

road grade.

“It’s only about 50 meters (164 feet) in length, but it’s called ‘the razorback’ for a reason,” said Karson Doyle, general superintendent. “It elevates very quickly and then it drops off very quickly.”

To build the steep embankment to access the river, crews excavated a total of 32,000 cubic meters, including 22,000 cubic meters of drill and blast.

After crews got through the structure, they filled an embankment leading to the slide site, where they built three “fingers” giving equipment access to multiple large boulders in the middle of the river.

That achievement, Doyle said, was notable because the fingers were built in Class 6 rapids. Classified by authorities as extreme and exploratory, these types of waters can be difficult and unpredictable.

Selecting the right equipment

Getting several pieces of heavy equipment to river level was another daunting prospect. Initially, the team considered transporting them by helicopter, dismantling each one as needed.

As the job progressed, however, they started to figure out the route could handle a little bit more, said Operations Manager Wes Prothe. “We knew a 30-ton excavator had been brought down the road before.”

Using that as a baseline, the team collaborated with Kiewit Infrastructure Engineering (KIE) to calculate the largest size of excavator that could make the sharp turns on the steep path. Ultimately, they determined that a 90-ton machine could do the job.

“The KIE and Western Canada teams did a really good job of not only saying ‘we think we can get a CAT 390 excavator down there’, but ‘we can get it down there safely’,” Prothe said.

Improving river hydraulics

As with any Kiewit project, safety throughout the process was a priority.

The time spent building the access allowed the team to install robust rockfall protection measures on the brow of the rock face 125 meters (410 feet) above the slide debris.

“Removing slide debris below this rock extended the available work window for the heavy equipment because less rock had the potential to ravel during high winds,” said Wilson.

One of the toughest jobs on the Big Bar project was clearing a path to get heavy equipment down to the river to clear landslide debris and restore the habitat for migrating salmon.

This excavator was used to build the toe of the embankment to minimize material loss in the river as trucks dumped blast rock from the top of the slope.

A reassuring approach

“In the end, we successfully gained equipment access to the slide debris and were able to address an estimated 14,000 cubic meters of rock within the channel — more than twice the projected scope in the bid documents,” said Wilson. “For scale, that is the equivalent of filling an entire hockey rink 30-feet high.”

Gwil Roberts, Big Bar Landslide Response director for DFO, said from the beginning of the project, Kiewit’s approach was reassuring — bringing a professional attitude, working diligently in an organized and respectful manner, and working well with First Nations, the province and the federal government on the response.

“We were very impressed from the start with that dedication to the project, the resources that were made available and the priority this project was receiving,” Roberts said.

And for the salmon, the approach paid off. Big Bar landslide is no longer an issue for fish passage. By the start of September, hundreds of thousands of salmon made it past the slide site naturally, and thousands used the fish transport system.