Two hours east of San Diego in the Southern California desert sits the Salton Sea, the state’s largest lake.

Salton Sea is a manmade lake, albeit not purposefully. In 1905, Colorado River floodwater breached an irrigation canal being built in the Imperial Valley. Water flowed into the low point of a closed drainage basin, forming the lake.

The 35-mile-long and 15-mile-wide lake became an important habitat for residential and migratory birds, with more than 400 bird species recorded at the site.

In recent years, drought and evolving water agreements have caused water levels to recede and salinity to increase. More lakebed is being exposed, impacting both wildlife and humans. Fewer fish can survive in the saltier water, reducing the available food source for birds, and increased dust from the exposed lakebed causes harmful pollution. To address these concerns, the Salton Sea Management Program (SSMP) was created as part of California’s strategic plan to improve environmental conditions at the Salton Sea.

The Species Conservation Habitat Project

The California Department of Water Resources (DWR) selected Kiewit Infrastructure West Co. as the design-build contractor for the Species Conservation Habitat (SCH) project, the first of many projects in the SSMP.

“This is an exciting, first-of-its-kind project to improve air quality and benefit local communities, while also providing habitat to migratory birds of the Pacific Flyway,” DWR Director Karla Nemeth said at the time the department released its request for qualifications for the project.

When the SCH project is complete, 4,000 acres of exposed lakebed at the southern end of the Salton Sea will have been covered, suppressing dust, and providing much-needed habitat for wildlife.

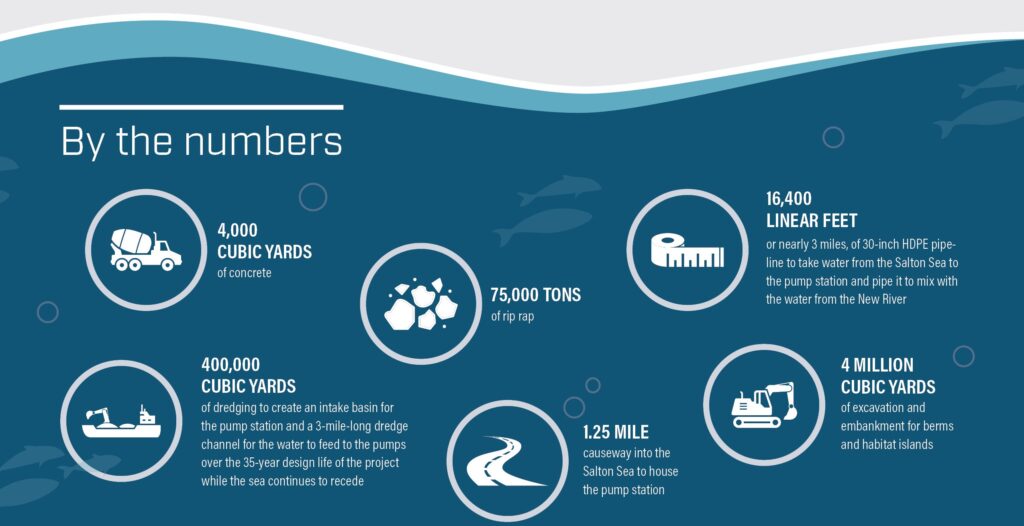

Excavated material was used to build embankments and form a wetland habitat. The habitat includes three large ponds of varying water levels, ranging from a few inches to 10 feet. A new diversion structure diverts water from the New River to mixing basins, where it is mixed with water that’s pumped from the Salton Sea, before entering the habitat’s ponds.

Amphibious equipment

The soil at Salton Sea is over-saturated and soft — more than 50% moisture content in many places.

“It’s wet enough in some spots that you can’t even walk,” said Kiewit Sponsor John Dunbar.

Where people can’t walk, traditional construction equipment can’t work either. While estimating the project, the construction team — led by Project Manager Robert Falk, a 29-year Kiewit and construction industry veteran with experience working with over-saturated soils — worked closely with Kiewit Equipment Services to select the right machines for the job.

“Our equipment group was a key partner on the job,” said Kiewit Construction Manager Evan Phelps. “They worked to understand our needs and come up with the best solutions based on equipment availability and time constraints.”

For Salton Sea, the right equipment had to be low ground pressure and multiple solutions were needed. Many of the units are almost amphibious in nature. A pontoon excavator and low ground pressure dozers and scrapers were among more than 150 pieces of equipment on site.

Drying out materials

Drying out materials

A key to the project’s success was processing over-saturated excavated material to make it suitable for the embankments. The optimum moisture content for the engineered embankments is 15% to 20%, depending on the material type. Many areas of the project had an initial moisture content of 50%.

Drying the material was a carefully managed and staged operation. Crews always needed 10,000 to 15,000 cubic yards of material available, ready to be taken to embankments. The disking and drying cycle took 10 to 20 days to complete. That meant over 100 acres of land was always open and in some stage of the process — disking, plowing or side casting.

“Our drying crews had to be well out in front to have material at optimum moisture ready for the scrapers to pick up,” said Construction Manager Evan Phelps.

“Having multiple plans for drying material was key,” said Project Engineer Lindsy Dugan. “We needed to have the flexibility to change how we used our resources depending on the actual conditions. When conditions in one area were different than expected, we needed to move resources around to not impact the overall schedule.”

Construction and conservation

While excavating and drying materials, building embankments and more, crews had to be very sensitive to local wildlife, including two endangered species — the desert pupfish and clapper rail, a marsh bird.

“Environmental sensitivity was a big part of the job and something we had to manage well to be successful,” said Phelps.

Some of the measures in place to protect the animals during construction included:

- Training all crews to identify signs of wildlife and notify the biological team

- Meeting regularly with the biological team and regulatory agency representatives to review upcoming work and mitigation measures

- Sequencing work in sensitive habitat near nesting, breeding and spawning windows

- Protecting materials with netting and wildlife materials to minimize impacts

- Ensuring onsite biologists clear areas ahead of work and during construction

- Working with California Department of Fish & Wildlife to trap and relocate pupfish prior to any work in their habitat

Setting the stage for success

Not only was SCH the first project in the 10-year SSMP, it was also DWR’s first major design-build project. The Kiewit team understood the significance of their role on a project of firsts.

“Partnering has been a big, big help on the job,” said Project Sponsor John Dunbar. “We have strong relationships at an executive level and at the local job level to be able to work through any issues. When you’re the first ones to be part of a new program, it’s not uncommon to have differences of opinion. But as a team, both sides have done a good job of making sure it’s a good experience for everyone.”

Kiewit plans to pursue future projects that are part of the SSMP.

More than 150 pieces of equipment were used to complete work on the Species Conservation Habitat Project.

Crews built a new diversion structure, which diverts water from the New River to mixing basins, where it is mixed with water that’s pumped from the Salton Sea before entering the habitat’s ponds.

Purpose and people

The Species Conservation Habitat project location made for some challenging working conditions. The remote location and hot desert temperatures required flexibility.

But for the Kiewit team, challenging circumstances aren’t uncommon. Building large, complex and remote jobs is standard. It’s a task that’s made worth it because of purpose and people.

“It’s the people and the fact that you know every project impacts that community,” said Dugan, when asked the best part about her job. “It’s a fulfilling job being able to really feel like you’re making an impact in the community. I’ve been fortunate to work with great people. They keep me coming back.”