Thanks to precision planning, hard work and collaboration, west central Florida residents can now boast of a power station that produces a new and cleaner source of energy.

The Big Bend Modernization project that wrapped up in December 2022, eliminated about half of the coal previously used at the Big Bend Power Station. The new state-of-the-art combined cycle technology project is capable of producing 1,090 megawatts. That’s enough electricity to power 250,000 homes.

The project was unique because it involved modernization of a 50-year-old existing coal-fired power station owned and operated by Tampa Electric Company (TECO).

Prior to modernization, Big Bend had four coal-fired units in operation.

TIC – The Industrial Company (TIC), a wholly-owned subsidiary of Kiewit Corporation, was hired as general contractor to modernize the oldest of the four units, converting it from coal to natural gas using combined-cycle technology. The change not only eliminated the use of coal in Unit 1, but it also reduced the amount of wastewater. The increased efficiency of the combined cycle and the retirement of two additional coal-fired units will provide a reduction in CO2 emissions up to 3 million tonnes from the previous full coal-fired operation at Big Bend.

The project was not without its challenges. The team had to work within a small footprint, inside an existing coal facility that was operational with overhead power lines and self-perform major demolition work.

Crews remove an old feed water heater as part of the demolition work needed to prepare Unit 1 for new equipment.

“Demolition is usually a smaller scope on projects like this, but we had over 55,000 hours of demolition work just to get the steam turbine building ready for the new equipment,” said Kayla Sisk, project manager. “We pulled out lube oil modules, feed water heaters, electrical, transformers and piping galore,” she said.

The demolition work took about 10 months and required extra coordination with the client and plant personnel to minimize the impact and disruptions to the existing facility, Sisk said.

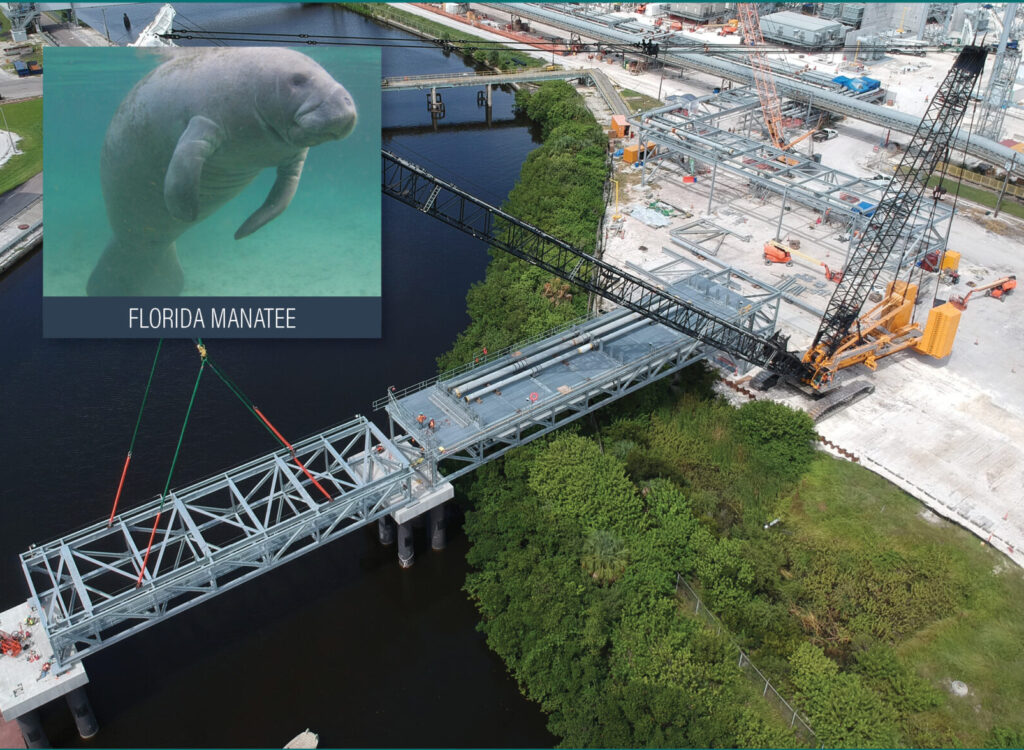

In addition to the demolition work and installation of combustion turbines and steam generators, the team had to construct a pipe rack that was 2,500 linear feet long for the steam piping. To make it even more challenging, the pipe rack included three bridge sections that spanned a canal.

“There were a lot of moving parts, a lot of different challenges throughout the process,” said Construction Manager Robert Door. “We ended up assembling the pipe rack in sections and then used a large crane to place them.”

Outstanding safety record

Throughout the four-year project (three onsite), the team achieved every critical milestone. They finished 2.3 million hours worked (1.7 million craft hours) without a recordable safety incident, all in middle of the pandemic.

Sisk attributes this outstanding safety record to the culture established early on by Door.

“Safety has been ingrained in me ever since I started with TIC as a craft guy back in 1998,” he said. “I always told myself that when I made it to construction manager, I would prove that we could do the job as safely as possible and still get it done,” Door said.

Door believes in being a staunch advocate for his projects and his people. Getting out in the field and having conversations with everyone is vital to him.

“It’s not just walking by,” he said. “It’s stopping and talking to people on the job, telling them why they need to do what they need to do and showing them.”

Team effort pays off

The Big Bend project wasn’t like the typical combined-cycle plants TIC builds under an engineer, procure, construct (EPC) contract.

In this case, the team included:

- TECO – owner, overall construction management and major procurement;

- Sargent & Lundy (S&L) – design, engineering, procurement support and construction management support;

- GE – supplier of two GE 7HA.02 gas combustion turbines and upgrade of existing steam turbine;

- TIC – construction, commissioning and start-up.

TECO acted as construction manager for the project and, in addition to the above team members, had its own subcontractors performing work within the areas that had to be coordinated.

Area Manager Mike Burton said it was a team effort from the beginning of the project with all parties focused on common goals, including finishing on-time and recordable free.

“It was a complex project and collaboration was crucial,” he said. “We all worked as a team with daily coordination on all aspects of the job.”

TIC brought its EPC mindset to the project.

“There were a lot of things we knew we could do better or faster or cheaper,” said Sisk. “We were very vocal about those ideas, and I think they respected us for that.”

Kris Stryker, senior director of Decarbonization Major Projects at TECO, said TIC was selected for the project because of its experience constructing plants using advanced technology gas turbines, experience that turned out to be valuable to the project.

“TIC was an excellent partner on the project, helping us resolve issues even outside their scope, and we were always able to come up with collaborative and creative solutions to the challenges,” said Stryker.

Another factor that set TIC apart was its safety culture and performance. “TIC definitely lived up to the sales pitch in this area by completing the project with zero recordables,” he said.

“I am most proud of our client relationship because we had a very engaged client with high expectations,” said Sisk. “To be successful, we needed to listen to their concerns and make sure we understood and addressed them.”

Protecting the manatees

The team faced a rather unique challenge on the Big Bend Modernization project — protecting the manatees.

Manatees are a threatened species and need warm habitats to survive. Tampa Bay’s Apollo Beach, home to the Big Bend project, is a popular gathering spot for these large marine mammals in the winter months because water from the bay that is used to cool the Big Bend Power Station is then circulated back into the bay as clean, warm water.

With such a large number of manatees migrating to this area, Tampa Electric built a Manatee Viewing Center, a state and federally designated manatee sanctuary open to the public from November to April. Although no longer listed as an endangered species, the manatees (also known as Florida’s gentle giants) still face many dangers, including loss of habitats. According to the Marine Mammal Commission, their slow speed and relatively high buoyancy make these “sea cows” vulnerable to boats. More manatees are killed as a result of boating accidents than any other single cause.

The project team at Big Bend had to take special precautions to protect the manatees.

“We had to make sure there was a manatee watch person when we were building the pipe bridge over the canal,” said Project Manager Kayla Sisk. “If a manatee was spotted coming into the canal, we would need to stop work.” Manatee watchers were also on duty anytime boats were being used.

The team had strict material handling procedures to make sure nothing was dropped into the water that manatees could eat or that could harm them. As it turned out, none of the manatees came close enough to the work area to force a shutdown.