The role of engineering and construction in the energy transition

The energy transition, a global strategy to reduce carbon emissions, is here to stay. A growing number of government entities, private companies, investors and consumers are backing the effort and have publicly declared targets and goals.

In the U.S., President Biden has set the goal of reaching 100 percent carbon pollution-free electricity by 2035. Some states, such as California, have even more aggressive plans, aiming to reduce carbon emissions to 40 percent below 1990 levels by 2030. In Canada, the federal government is committed to reducing emissions to 30 percent below 2005 levels in less than a decade, by 2030.

In the private sector, large global companies — including Microsoft, BP, American Airlines and Nestle — have all publicly committed to net-zero targets. Private equity firms are taking unprecedented steps to decarbonize their portfolios. And global sales of electric vehicles are at an all-time high, increasing by more than 40 percent in 2020.

The goals have clearly been set — now what?

“The path forward will require all of us to stretch our thinking, facilitate new collaborations and embrace innovation,” said Dan Lumma, who leads engineering services at Kiewit. “It will also require extensive engineering and construction ingenuity, which we are prepared and well-equipped to provide.”

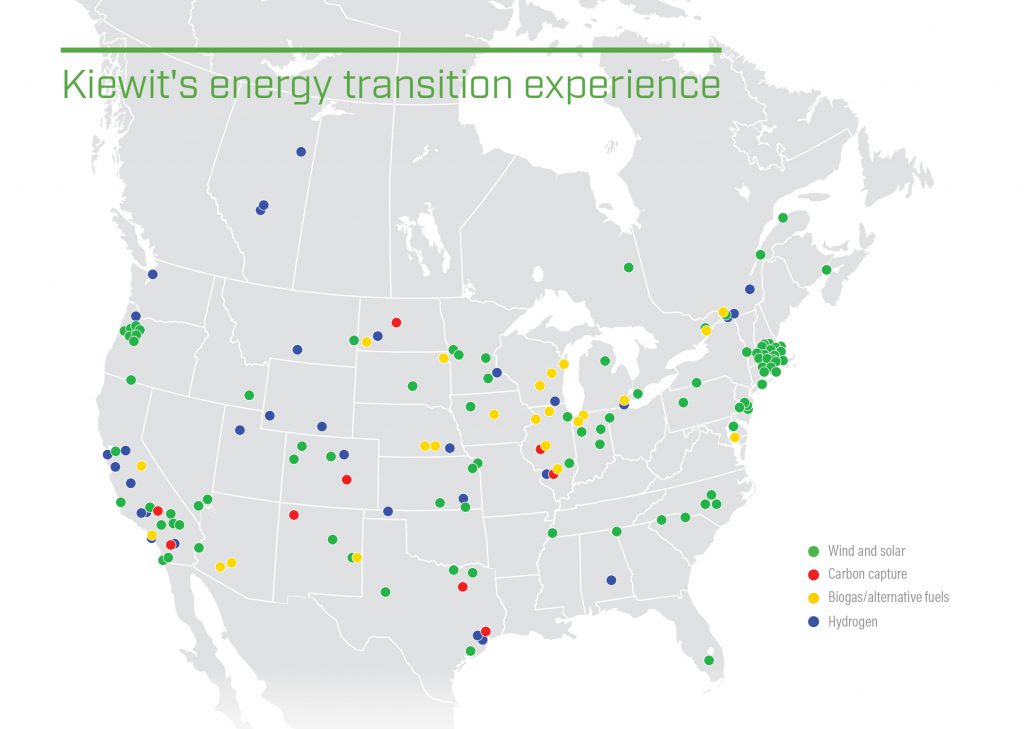

While decarbonization is complex and multi-dimensional, there are three general areas in which Kiewit can help:

1. Retrofitting facilities and systems to reduce or eliminate carbon emissions

2. Increasing the use of renewable energy resources

3. Helping industrial operations meet the new demand for products, such as hydrogen and ammonia

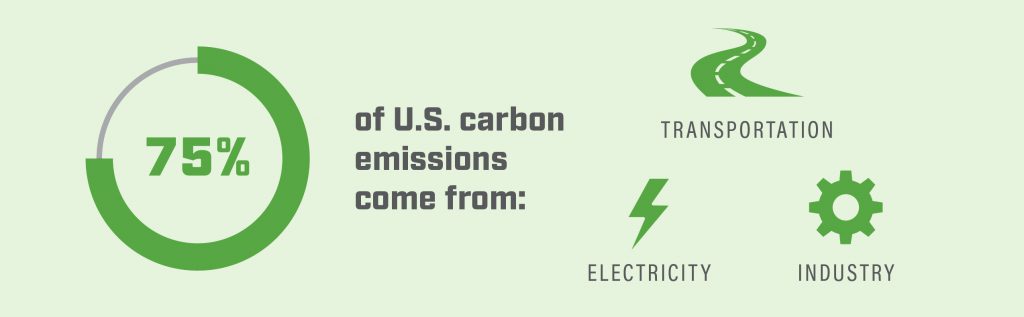

Reducing, capturing and converting carbon

Nearly everything we do, either directly or indirectly, emits carbon — from the clothes we buy to the food we eat and the homes we heat. However, there are three major sources that comprise roughly 75% of carbon emissions in the U.S.: transportation, electricity and industry.

“We’ve been working with clients in these markets for decades and understand the opportunities and challenges of their business and facilities,” said Matt Thomas, a leader in Kiewit’s power engineering business. “This foundational understanding gives us a head start in helping them transition to lower carbon intensive operations.”

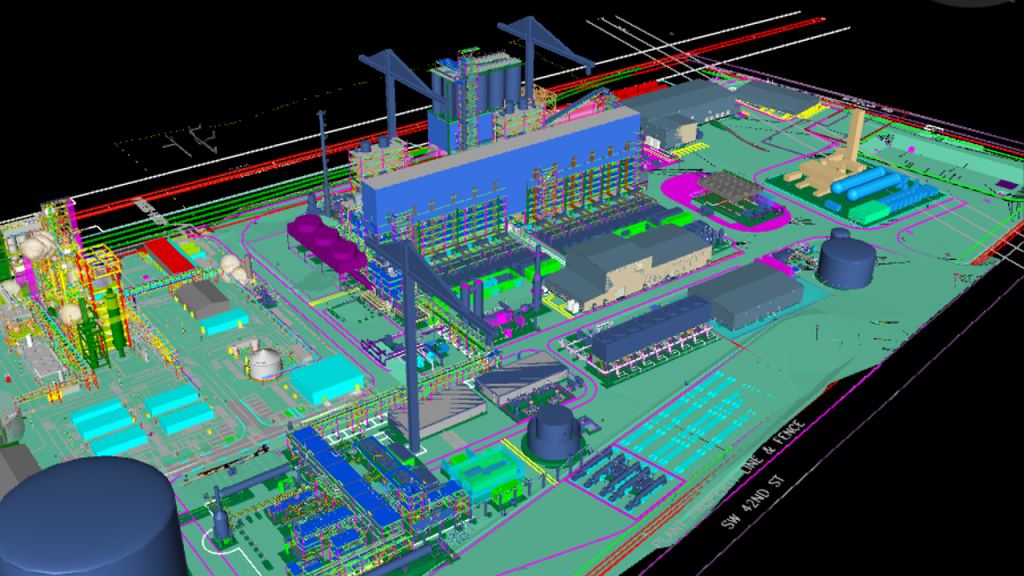

In the power generation market, carbon capture, utilization and storage (CCUS) technologies are now a proven solution in mitigating emissions. In 2017, the first commercial-sized post-combustion carbon capture system in the U.S. began operating at Petra Nova in Thompsons, Texas. Kiewit and its subsidiary, TIC – The Industrial Company (TIC), served as the engineering, procurement and construction (EPC) contractor for the facility.

More recently, Kiewit has devoted countless time and resources to various CCUS research and pilot projects, including an engineering study backed by the U.S. Department of Energy to retrofit an existing power generation station in Illinois with a system designed to capture 95 percent of carbon emissions. Kiewit has also conducted a detailed analysis of direct air capture (DAC) technology — a process where CO2 is removed from the atmosphere through chemical processes. The analysis includes information and guidance on cost, supply chains, materials and labor requirements that can help streamline decision-making by facility owners. The potential impact of this type of research is tremendous as it can help fuel more widespread adoption of CCUS at coal, natural gas and industrial facilities across North America.

In the transportation market, the availability and accessibility of public transit plays an important role in reducing carbon emissions. Building or expanding these systems can be time and cost intensive; however, the use of alternative project delivery methods is helping to streamline budgets and schedules.

Beyond public transit, new electrification technologies continue to gain momentum in the transportation market. Specific infrastructure is needed to support the increased use of electric vehicles among individuals and large company fleets. Advancements continue to be made in vehicle-charging stations as well as the emergence of new technologies, such as dynamic electrical vehicle charging, which allows vehicles to charge as they are driving down the road.

To fully integrate electric vehicles into transportation networks, local utilities also need to ensure that the electrical grid can support electrification. For example, FedEx has set its sights on electrifying its entire fleet by 2040 — an estimated 77,000 vehicles in the U.S. — which will affect when, where and how much electricity the grid will need to deliver.

New investment in renewables

Wind, solar, geothermal and hydroelectric have been a mainstay in the production of renewable energy for many years. Kiewit has been working in these markets for more than four decades, but the speed of innovation in renewable energy has increased significantly in recent years. For example, wind farms are expanding from on-land to offshore, and bifacial photovoltaic modules are more efficiently harnessing the power of the sun.

“We’ve assembled a team and strategy to stay ahead of emerging technologies so that we can thoroughly evaluate how they might fit with our clients’ needs,” adds Thomas. “Through Kiewit’s highly specialized subject matter experts, we can help make the best decisions to get the best results.”

There is also renewed interest and investment in other renewable energy sources. The use of renewable diesel is on the rise, most notably in California, where the Low Carbon Fuel Standard has triggered demand for alternative fuels. The conversion of several existing petroleum-based refineries is currently underway, which transform vegetable and animal fats into renewable diesel. Combined heat and power systems (CHP) are also being retrofitted to use biogas and wood waste as fuel, reducing dependency on natural gas. In Maryland and Wisconsin, Kiewit is providing engineering and construction services to farming operations where poultry litter and dairy farm manure are converted into fuel.

New markets and revenue streams

The National Renewable Energy Laboratory (NREL) projected a four-fold increase in the demand for hydrogen by 2050. The growing popularity of hydrogen is partially driven by its versatility since it can be used as a fuel source as well as feedstock in many industrial operations. For example, hydrogen can be used to power combustion turbines instead of natural gas. Many CCUS technologies also support clean hydrogen, ammonia and ethanol production.

As a result, there are new commercial opportunities and revenue streams to meet this demand.

“We recently had a call with a client to discuss how they might turn the carbon emissions at their facility into a revenue stream,” said Travis Shearer, vice president of Kiewit’s energy group. “Due to the breadth and depth of Kiewit’s experience and capabilities, we were able to pull together the right subject matter experts that can transform an idea into the real deal.”

Beyond hydrogen, there is also an uptick in the demand for ammonia. Kiewit is currently the EPC contractor for the first large scale, carbon-free ammonia plant in the U.S. The facility will utilize proprietary technology to produce anhydrous ammonia and carbon black, which are key ingredients used to manufacture fertilizer, tires, cables, batteries and other products.

“Our ability to successfully execute industry-first projects is a testament to our talent and agility; however, it is also driven by our unique distributed execution model,” said Rob Zinsmeister, the engineering manager for Kiewit’s oil, gas and chemical business. “Kiewit has centralized expertise and local execution capabilities, resulting in a more streamlined approach since we can mobilize faster and understand the local labor market.”

Looking ahead, there are several noteworthy innovations on the horizon:

– A process in which carbon can be absorbed by algae and used to make products, such as soil supplements and food for fish or livestock

– New solutions that can convert carbon into chemical products that are used to manufacture plastics, pharmaceuticals, carbon fiber and synthetic fuel

– The ability to purify, store and inject carbon into concrete.

“There is an unprecedented level of innovation and cross-pollination with process, power and industrial engineering,” said Alastair Cullen, who is on the front lines of Kiewit’s business development efforts. “It is an exciting time to work in engineering and construction, where we can make a meaningful contribution to the energy transition.”

Petra Nova Carbon Capture Project, Texas - The first commercial-size post-combustion carbon capture system in the U.S.

Ottawa LRT Stage 2, Ontario - The use of public transportation plays a critical role in reducing carbon emissions. In Ottawa, 77 percent of residents will be within 5 kilometers of rail once the Stage 2 project is complete.