A demolition project in the San Francisco Bay has all eyes watching the waters.

Every day, about 270,000 vehicles make the commute between San Francisco and Oakland via the Bay Bridge. But it’s what remains in the water below that’s the focus of Kiewit/Manson, AJV and their client, the California Department of Transportation (Caltrans).

In 1989, the Loma Prieta earthquake rocked California’s San Francisco Bay Area. The 7.1 magnitude event and the damage it caused prompted Caltrans to initiate a seismic retrofit of the San Francisco-Oakland Bay Bridge, including complete replacement of its east span. Construction began in 2002 and the new structure opened to traffic in 2013.

With the new bridge in place, attention then shifted to dismantling its predecessor. One of the most challenging tasks? Removing the marine piers which served as the old bridge’s foundation.

Lurking under the bay’s surface, the piers measured, on average, 100 feet long by 30 feet wide, with the largest footings extending over 180 feet below the cold waters.

Caltrans and its construction manager/general contractor, Kiewit/Manson, AJV, developed an innovative solution to get the job done: use more than 80,000 pounds of explosives to implode the more than 40,000 cubic yards of concrete that made up the 15 submerged footings.

The method had never been used before in the Bay Area, a community which Caltrans Chief Bridge Engineer Brian Maroney calls a “world leader in environmental balance.” Of particular interest to residents: how would the team protect more than 70 species of fish and four species of marine mammals that call the bay home, as well as more than one million birds that stop or winter on the waterway?

From 2002 to 2008, Kiewit/FCI/Manson, JV constructed the Skyway and E2/T1 segments of the new San Francisco-Oakland Bay Bridge east span replacement. The Skyway Segment project included twin 1.2-mile-long bridges. The E2/T1 Foundations project involved constructing the foundations for the new self-anchoring suspension (SAS) bridge.

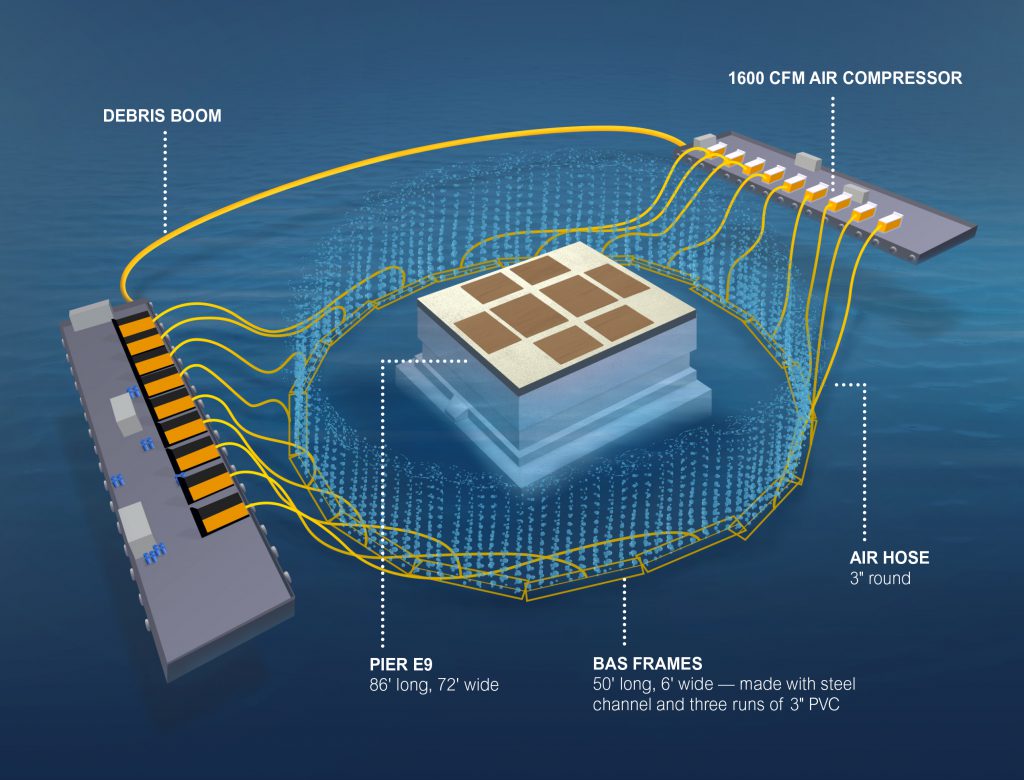

Programmable explosives and blast attenuation systems (BAS)

Protecting native species, as well as adjacent infrastructure like the new Bay Bridge, a Bay Area Rapid Transit (BART) tunnel and a nearby high-pressure gas line and water treatment outfall, were top priorities as work was planned.

“Reducing the blast energy released was a crucial component of the project and one that we’ve worked diligently on from Day One,” said Keith Boulton, a Kiewit/Manson, AJV marine superintendent.

The team’s diligence led to the development of a two-pronged solution to mitigate the effects of high-blast energy on the surrounding environment.

First, using programmable explosives, millisecond delays were incorporated between the detonation of each charge. The delays, while nearly unnoticeable, ensure that only a very small quantity of explosives was detonated at any particular moment.

“During each individual implosion, instead of one really big blast detonating 15,000 pounds of explosives all at once, you end up with a series of 500 mini blasts, each detonating about 30 pounds of explosives,” said Zach Reilly, Kiewit/Manson, AJV project manager. “The result is a slightly longer blast duration with a greatly reduced peak energy release.”

Second, a blast attenuation system (BAS) reduced the effect of the blast by creating a wall of air — or “bubble curtain” — and was especially effective at protecting nearby marine life.

“The BAS uses up to 19 high-volume compressors to pump more than 31,000 cubic feet per minute of air to a network of pipes that circle the foundations on the bay floor,” said Joe Eiras, Kiewit/Manson, AJV safety and environmental manager. “When the compressors are fired up, a 5-foot-wide wall of air bubbles rises upward from the bay floor, surrounds the pier, and decreases the shock during

the implosion.”

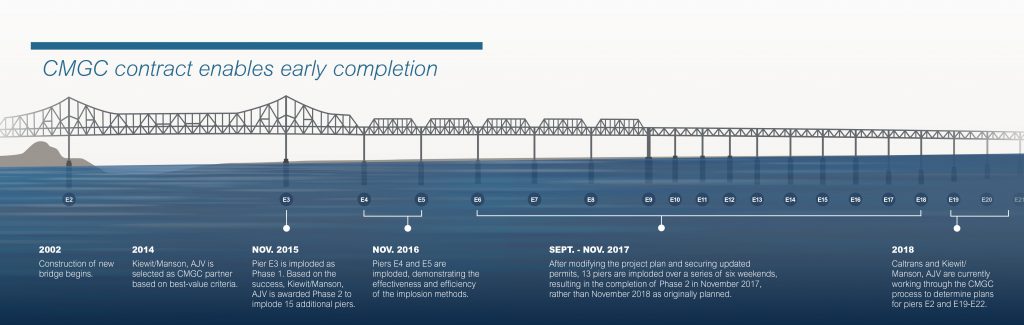

Ahead of schedule

Each foundation implosion lasted just seconds. However, bringing the plan from blueprint to blast took a lot longer. Careful consideration had to be given to the June 1 to Nov. 30 in-water work window as permitted, and the Sept. 1 through Nov. 30 explosives blast window.

“When we started the project, we anticipated needing all of the 2016, 2017, and 2018 in-water work windows to complete the job,” Reilly said.

But after successfully removing two of the foundations in 2016 and demonstrating the effectiveness of the controlled implosions and the BAS, the team set its sights higher.

Working closely with permitting agencies, Caltrans and Kiewit/Manson, AJV secured an early start to above-water work in 2017 and modified their project plan to implode up to four foundations in a single blast event, as opposed to the original plan that allowed for only one pier per implosion.

On Nov. 11, the last piers were removed from the bay – a full year ahead of the originally anticipated 2018 completion date.

Reilly credits the early finish in part to the contract model chosen for the project.

“The CMGC model allowed our team to truly partner with Caltrans, leverage each group’s unique strengths, and work collaboratively with the numerous other agencies and organizations associated with the project. It was a difference maker and I think a huge success for all the stakeholders.”

The project was procured using the construction manager/general contractor (CMGC) contract model. It allowed Kiewit/Manson, AJV and Caltrans to partner together and work through challenges earlier, and ultimately finish the project a year ahead of schedule.

’A really smart team’

Like Reilly, Maroney can’t say enough good things about the partnership.

“Kiewit/Manson brought a really smart team to the group. They’ve not even hesitated, they haven’t even blinked an eye and they’ve been 100 percent supportive in helping make sure these parameters are monitored at a superior level.”

“Kiewit’s reputation of following the rules is really valuable. People have a lot of confidence in the team. When the rules are laid out environmentally, they’re going to follow them, and we count on that.”

Embracing the fundamentals is part of Kiewit’s approach to any job, Reilly said.

“I think the team has done a great job of working with the client. We’ve been innovative in our means and methods, and we haven’t settled.”