The construction industry is facing a generational shift. Kiewit is investing heavily in hands-on training and long-term careers to close the gap, and Francisco Ozaeta Jr. is one example of how that investment is paying off.

Long before Ozaeta stepped on a jobsite, he was just a kid watching his dad work. His father, a plumber, could fix almost anything, but what stuck with Ozaeta wasn’t the tools. It was the way his dad, who now owns his own plumbing business, built something lasting with his hands.

“I’ve always wanted to be like him,” Ozaeta said. “He is my idol.”

That admiration became a blueprint for his work ethic and the driving force behind his successes at Kiewit. Ozaeta started at the company as a helper, an entry-level role supporting the crew with basic tasks, but it didn’t take long for him to stand out. During rigging training, he was the only one to pass every written and hands-on test.

“It was a proud moment,” he said.

He was then chosen to lead the project’s safety program, a move that paved the way for his promotion to structural foreman. In that role, he managed the safe lifting and movement of heavy materials. His leadership didn’t go unnoticed. He was named a Key Craft employee, a recognition for top-performing craft professionals. From there, he earned a spot in the Accelerated Journeyman Development Program (AJDP), a training track for emerging craft leaders.

“Being chosen makes me feel valued,” Ozaeta said. “It makes me feel like Kiewit wants me to succeed and move up.”

In early 2025, he completed his first AJDP course in Texas under Ironworking Instructor Hugo Mosqueda, who said Ozaeta stood out early in class for his sharp questions, detailed notes and ability to apply what he learned in the field quickly.

“His dedication, humility and drive to grow make him a solid investment for what he can do now and the potential he continues to show every day,” Mosqueda said.

Next, Ozaeta will head to Kiewit’s Training Center in Aurora, Colorado, for advanced instruction through the company’s National Center for Construction Education and Research (NCCER)-accredited curriculum, continuing the same structured path that’s preparing future craft leaders.

Meeting the moment

Ozaeta’s rise is just one example of how Kiewit is preparing for the future. As experienced craft workers approach retirement, companies like Kiewit face growing pressure to develop more high-quality skilled talent and new leaders.

A 2018 report by NCCER and the Construction Industry Institute projected that 41 percent of the construction workforce will retire by 2030.

Andrew Pate, who manages Kiewit’s Training Center, is one of the people preparing for that shift.

“Companies will need to start hiring people who don’t necessarily have experience,” Pate said. “That’s why training is going to become even more important, especially over the next five years, to make sure our quality of work continues.”

Kiewit has expanded training beyond its Colorado facility, now delivering 75 percent of instruction through mobile training facilities (MTFs), which are converted shipping containers used as portable classrooms on the jobsite. Participants are nominated by supervisors based on tenure, safety, reliability and growth potential.

Feedback shows trained employees feel more valued and are more likely to stay.

“Our schedule is nearly full for the year,” said Pate. “And the need is only growing.”

Kiewit’s workforce development team met with Southeast Lineman Training Center graduates to build relationships and strengthen the craft talent pipeline.

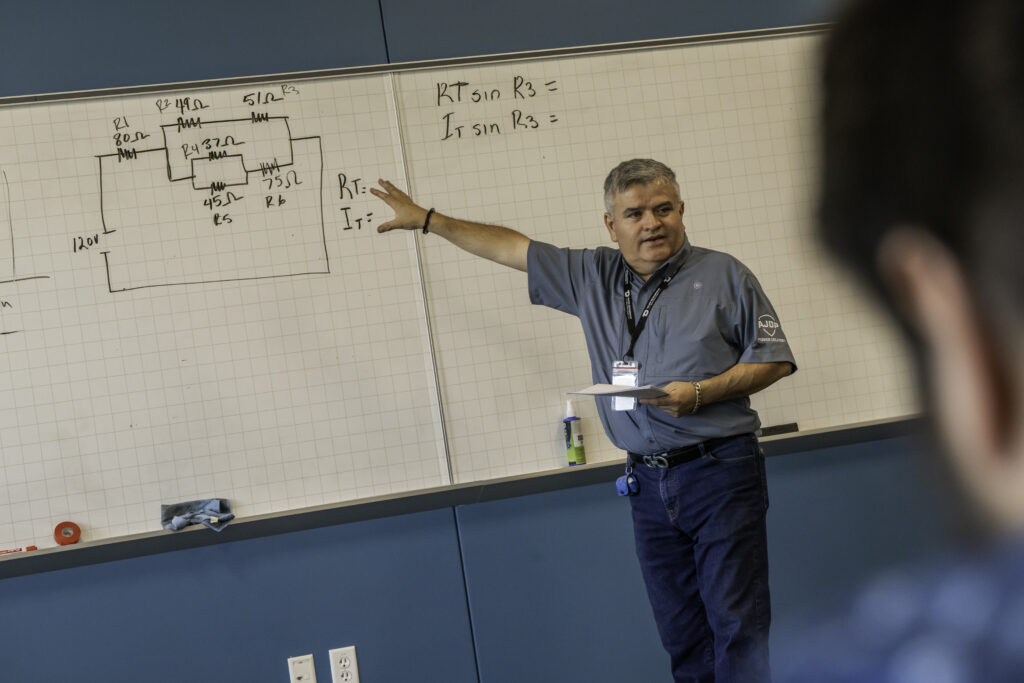

An NCCER-certified instructor leads a power delivery training session in Spanish, ensuring language is never a barrier to learning and advancement.

Powering the future

One area experiencing increased demand is power delivery, where skilled lineworkers are becoming increasingly hard to find. The center has begun training employees specifically for those roles through the AJDP power delivery program.

“Within four years, this program prepares you to work in one of the most exciting industries in construction,” said Vance Brison, who leads power delivery craft apprenticeships.

Classes are taught in English and Spanish by NCCER-certified instructors. The program has trained over 80 apprentices since 2023, with more than 50 currently enrolled. Participants focus on transmission, substation or distribution work using simulators, pole yards, a transformer lab and virtual reality.

“The type of recruit we want in our program isn’t necessarily the one with the best GPA or the fastest up a utility pole,” said Brison. “It’s someone with the right attitude, who is willing to learn, work and grow. That’s the Kiewit culture we strive for.”

As new projects emerge and the workforce ages out, Pate sees now as a great time for the next generation to enter the construction industry.

“Finding a company that pays for all of your training? That’s rare,” Pate said. “If you show up, work hard, have good attendance and a solid safety record, your chances to move up and make more money go way up. And that means a better life for your family or whoever you’re working to support.”

Expediting the pipeline

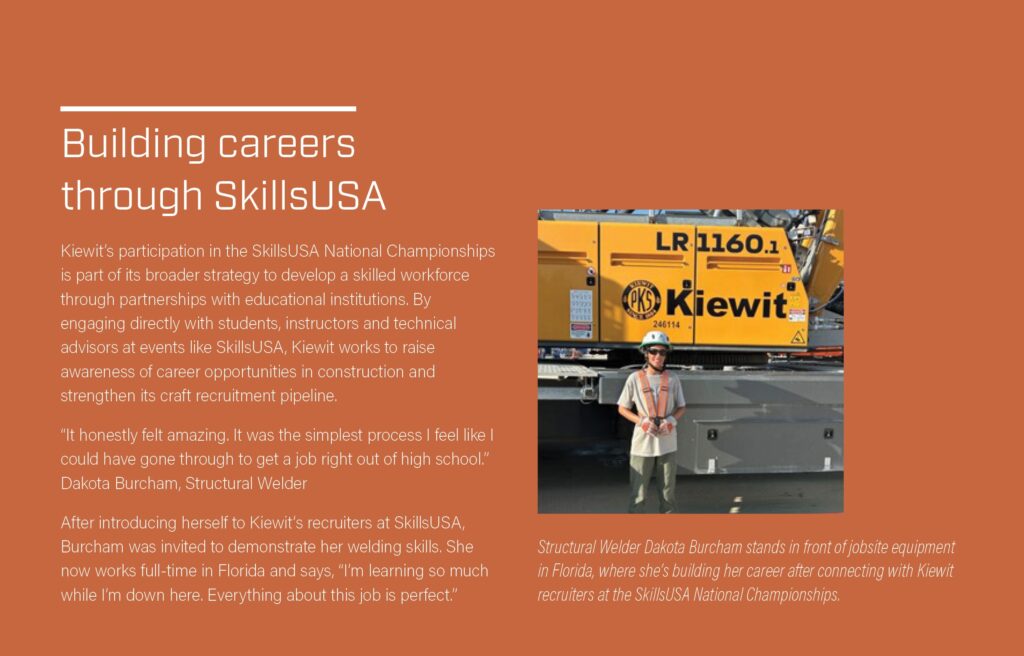

Construction hiring used to prioritize speed, experience and local availability. Today, the focus is on building long-term careers and widening access to the trades.

“For someone just out of high school, getting into the trades can feel out of reach,” said Ron Duce, who leads workforce development at Kiewit. “Without a connection, it’s hard to start.”

Hiring managers typically look for candidates with construction experience. “To grow the workforce, new entry-level talent needs to be given the opportunity to join organizations and develop their skills,” Duce said.

Kiewit is now centralizing workforce development and investing in long-term relationships with trade schools nationwide. The goal is to build a reliable pipeline, not just fill open roles.

“We invest in a core set of vocational schools that meet our long-term craft recruiting strategy for the company overall,” said Gabriel Cambrelen, craft workforce development lead. The strategy mirrors Kiewit’s long-standing approach to hiring engineers. “Now we apply that structure to craft roles, placing talent as company hires, not just project hires.”

Kiewit now partners with more than a dozen institutions, including Oklahoma State University Institute of Technology and Southeast Lineman Training Center. Each aligns with specific trade needs like diesel techs, crane operators, linemen and more. The company celebrates direct hires through signing days, offering students a clear path into the company.

“Commitment and effort matter,” Cambrelen said. “We meet that with opportunity.”

Ozaeta is living proof of what can happen when someone shows up ready to meet the company’s investment with effort. He now considers his ironworking instructor, Mosqueda, a mentor. The patient teaching style Mosqueda brought to the classroom now shapes how Ozaeta leads.

“Sometimes you have a guy who’s not getting it,” he said. “And I’ll ask myself, how would Hugo handle this?”

That mindset of staying present reflects how Ozaeta approaches the job. He is the one who volunteers for weekends, picks up extra shifts and stays late when needed.

“They don’t have to tell me they see it,” he said. “I can feel it. We’re moving forward together, me as a worker and them as a company.”

His advice to others is simple: show up every day, be willing to learn and do more than what the job description says.

“Opportunities will come, but you have to be there,” he said. “If you go the extra mile, it will pay off.”

Ozaeta’s extra effort has paid off in more ways than one. Each time he earns a new title, he makes the same call.

“Hey, Dad, I did it.”

His father doesn’t say much. Never has. “He’s old-fashioned,” Ozaeta explained with a laugh. “Getting a ‘good job’ out of him is like pulling water from a rock.”

But Ozaeta doesn’t need to hear the words.

“I can hear it in his voice,” he said. “I can see it in his face. He’s glowing with pride.”

And for him, that is the ultimate satisfaction.