Five bridges. A remote gorge. One shot each winter to get it right. Despite a hurricane, tough terrain and off-season construction, Kiewit keeps crucial bridge project on track.

Deep in the Pigeon River Gorge where the Great Smoky Mountains meet the Pisgah National Forest, a monumental infrastructure project is reshaping a vital corridor of Interstate 40.

The $201 million project will replace five aging bridges along this remote stretch of highway — structures that have been in place since the 1960s.

“These bridges are showing their age and no longer meet modern standards,” said Josh Deyton, division construction engineer with the North Carolina Department of Transportation (NCDOT). “Our goal is to ensure they serve the community for decades to come.”

With traffic on I-40 increasing by 43 percent over the past 15 years, the project is an essential but complex operation of precision, innovation and resilience — carried out in one of western North Carolina’s most challenging environments.

Tackling traffic and terrain

Awarded to Kiewit Infrastructure South Co., the project has required navigating high elevation, steep slopes, tight work zones and heavy seasonal traffic.

The area sees a surge in visitors from May through October, leaving only the winter months for construction, which is the off-season for asphalt and concrete work.

Another challenge? Traffic had to remain open throughout construction. To manage the flow, the team rerouted vehicles to exit and entrance ramps for the first bridge and tackled two lanes at a time for the remaining four.

Meeting these logistical demands required strategic coordination — something the team prioritized from the project’s inception.

Teamwork from the start

The project’s success is rooted in early collaboration made possible by the Construction Manager/General Contractor (CMGC) model, which pairs contractors and designers before plans are set. This project marks NCDOT’s first use of the delivery model on one of its projects. Deyton praised this proactive approach.

“We were able to work through construction methods and sequencing for each bridge early in the process, and that helped us make some design decisions,” he said. “That, to me, was where the process really shined.”

This early collaboration laid the foundation for creative solutions on the ground. This would prove essential on two of the more complicated bridge builds on the project.

Innovation at new heights

Jonathan Creek Bridge, aptly nicknamed the High Bridge, towers 100 feet above its namesake creek. To demolish the 600-foot bridge, the team had to use special equipment and protection to keep debris from falling into the creek.

To accelerate work, they deployed TyBOT, a robotic rebar-tying machine that completed 58,215 ties across 25,154 square feet — averaging more than 1,100 ties per hour. Project Engineer Brett Kauffman equated the robot’s output to the work of four people.

The Pigeon River Bridge posed another logistical challenge. The three-span bridge stands at about 50 feet tall, stretches 364 feet long and spans 81 feet wide. Its girders — 63-inch Florida I-beams — range from 96 to 130 feet long and weigh between 52 and 71 tons.

Rather than using costly cranes for a brief lift, the team devised a gantry system attached to the new bridge substructure.

“They came up with a gantry-like system to pick the girders up off the existing bridge deck, shift them over horizontally and then lower them back down,” said Deyton. “It’s a very innovative way of setting the girders.”

Timing is everything

In addition to overcoming the constructability and access issues, Kauffman said planning, phasing and material procurement were key to the project’s success. The project’s remote location extended material delivery times, which had to be factored into the schedule.

The project was divided into three strategic phases, bundling bridges by location. Rigorous pre-planning minimized delays and kept construction moving during tight seasonal windows.

“Getting staff and equipment to the site required meticulous planning,” said Project Manager Luke Silvus. “We hire as many locals as possible, and then supplement with our loyal craft following who travel with us to our most challenging projects.”

Despite winter weather, the team maintained progress by partnering with local concrete and asphalt companies to guarantee material availability.

The first bridge was completed in 2022, and two more were finished in May 2024. The final two bridges remain on track for completion in October 2026.

Alongside technical obstacles and scheduling demands, the team also had to navigate the area’s ecological sensitivities.

Safe passage

Located near a national forest, the area is home to bears, elk, deer and other species.

Deyton said environmental permitting took longer than expected due to the presence of an endangered bat species that roosted on one of the bridges.

“We could only demo the old bridge when the bats were migrating,” he said. “And we had to construct bat boxes on the new bridge for when they returned.”

To protect animals and motorists, the team installed wildlife fencing throughout the project area. Wildlife guards were added to entrance and exit ramps to prevent elk and deer from entering the road.

Kauffman said the team also installed jump-outs in the fencing to allow animals a way out if they became trapped, and left breaks in the riprap around bridge abutments to maintain natural pathways.

But safety on the project didn’t stop with wildlife. Silvus said he’s proud that despite the tough terrain and winter work windows, the crew has completed four years of the five-year project without a single injury.

Built to last

As the project enters its final phases, the I-40 bridge replacement continues to highlight the value of early collaboration, smart planning and innovative thinking. Despite the challenges, the team remains on track — a testament to their resilience and commitment to lasting infrastructure.

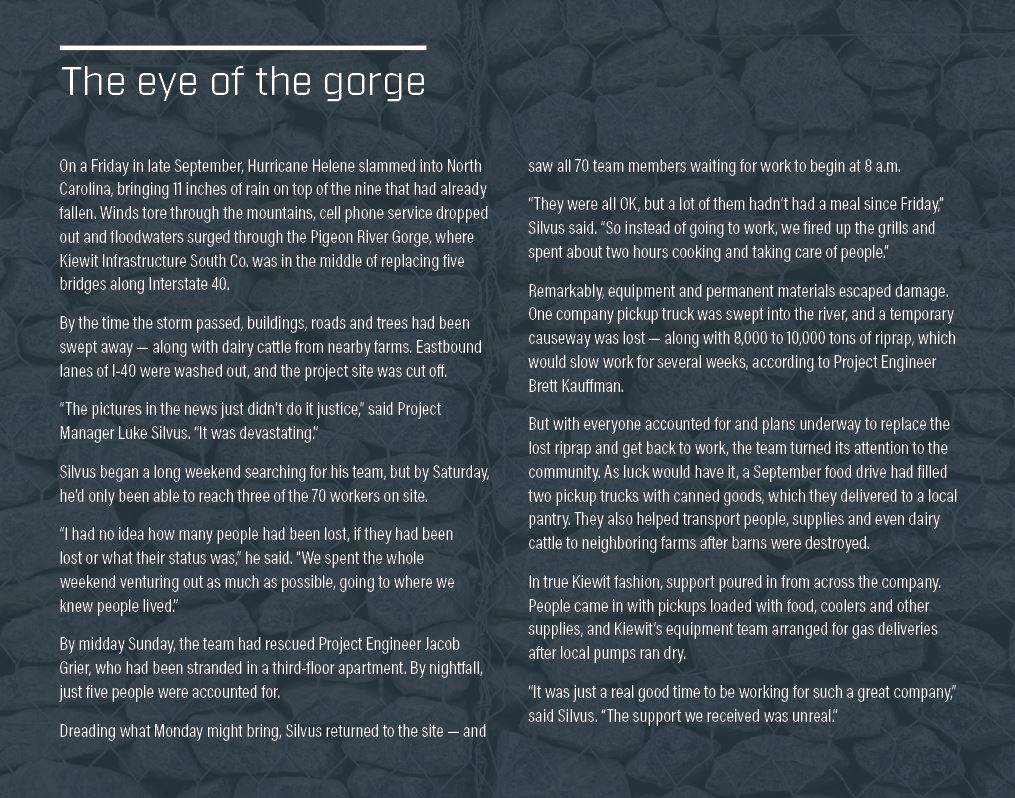

The Kiewit team gathers on the rebuilt causeway, restored after the storm washed away more than 8,000 tons of riprap. On the left, a neighboring property near the jobsite bears the scars of the flood, its riverbank deeply gouged by Helene’s wrath.