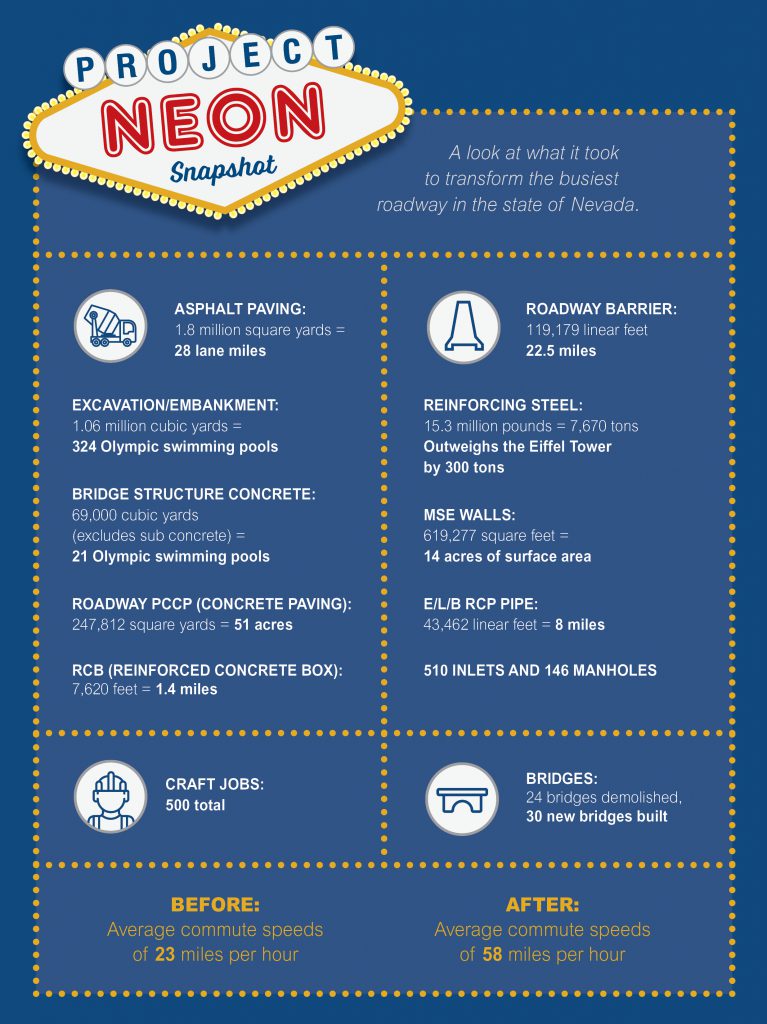

Las Vegas commuters will likely feel they’ve hit the jackpot this summer when Project NEON is complete. Three years in the making, the design-build project led by Kiewit Infrastructure West Co. is transforming a key roadway near downtown Las Vegas.

With a price tag of nearly $1 billion, Project NEON is the largest and most expensive transportation public works project in Nevada’s 154-year history. For northbound I-15, travel speeds will increase from 28 miles per hour to 60 miles per hour. For southbound I-15, average speeds at peak morning and evening drives will increase from 18 miles per hour to 56 miles per hour.

For years, the 3.7-mile stretch of I-15 between Sahara Avenue and the “Spaghetti Bowl” interchange has tested drivers’ patience.

An estimated 300,000 commuters — that’s one-tenth of Nevada’s population — travel this thoroughfare daily. The corridor sees 25,000 lane changes per hour. An unlucky three vehicles are involved in a crash every day.

It’s the most heavily used roadway in the state of Nevada. And with traffic in the area expected to double by 2035, city and state officials knew a fix was in order.

The vision for Project NEON was born nearly 20 years ago. By 2013, the Nevada Department of Transportation (NDOT) was accepting bids for the design-build project.

Kiewit’s winning proposal, featuring an accelerated completion schedule that beat the nearest competitor by six months, set in motion in July 2016 a transformation that will not only impact local traffic but also interstate commerce from Los Angeles to Salt Lake City.

Beyond business as usual

Project NEON involves much more than just rebuilding 3.7 miles of roadway.

Kiewit’s work includes building an 81-foot-tall, 2,606-foot-long High Occupancy Vehicle (HOV) flyover bridge, as well as converting two existing I-15 express lanes into a general purpose and HOV lane.

Also included in the project is a diamond interchange designed to improve access to downtown, the city’s medical district and Symphony Park. Several “braided” ramps will reduce merge and weave traffic on I-15.

To meet every milestone on time and on budget, the Kiewit team knew this project needed to go beyond business as usual.

That meant bringing team members together for the usual play-of-the-day midday meeting. Project foremen and superintendents also gather in the morning; later in the day, the night shift and their foremen and superintendents meet.

These three-a-days happen up to seven days a week. “They’re necessary to the choreography required in a relatively small footprint like this one,” said Structures Manager Chris Miske.

“There are just a lot of details and parts and pieces. It’s important that we communicate and coordinate with other disciplines prior to the start of work so they all know when we’re working in that area, and how big our access and work areas need to be so we can all co-exist.”

Dale Keller, NEON project manager for NDOT, says he appreciates the extra communication Kiewit has brought to the job and it shows every day.

“Kiewit is definitely the most organized contractor I’ve ever worked with. They’ve really exceeded expectations on allowing us to participate in the play-of-the-days, providing input where necessary and talking with staff as well as the crews in the field.”

Changes on the fly

There’s another equally crucial kind of choreography on this job.

That involves the Maintenance of Traffic (MOT) phasing — the plan that keeps traffic moving during construction by designing effective alternate traffic patterns and keeping drivers updated about changes.

Being co-located with Atkins, the lead project designer, has made a difference in how the entire team communicated MOT design changes to work well with construction, said MOT Manager Mike Whittick.

“We always had free access to help improve our MOT designs or change them so they would work better with construction. Nothing was locked in, and our relationship with NDOT allowed us to make changes that would make improvements relatively on the fly after approvals.”

That relationship, Whittick said, made it possible to shrink the timeline for MOT closures in some cases to as little as overnight. The resulting changes allowed the Kiewit team to complete closures sooner, helping to avoid big impacts to drivers.

Speeding up construction time

Achieving substantial completion by summer 2019 has also involved implementing some accelerated construction methods, like the type of bridge girder used for the majority of the 30 super structures.

Constructing typical steel girders requires a lot of lead time. Using a precast concrete girder instead can shorten construction time considerably.

For projects like these, Kiewit uses a California wide flange girder. Its shorter, wider base meets the height restrictions while minimizing the number of girders needed for each bridge.

“Normally, we figure out a way locally to get our precast concrete girders, but NDOT hadn’t really used that method and nobody in Las Vegas was set up to construct them,” said Jody Schott, project director.

Kiewit looked beyond geographic boundaries and brought in nearly all the girders from Arizona.

“That was a huge effort to coordinate that,” Schott said. “They came all the way across Arizona with Arizona Department of Public Safety officers escorting them in front and back.”

The decision has paid off, shaving as much as two months off a traditional schedule. In total, 422 precast girders will be set, including the longest precast components in the state of Nevada at 168 feet.

A first-of-its-kind system

For one particular part of the project, Kiewit’s work has extended beyond the main footprint to about 10 miles of the I-15 strip and the U.S. 95 corridor.

The team has been involved in NDOT’s implementation of a first-of-its-kind active traffic management system (ATMS) for the state.

The system uses full-color, high-resolution dynamic message signs over the roadway — think a stadium scoreboard — to communicate real-time information about alternate routes, incidents and traffic restrictions.

ATMS detectors collect data on average speeds, pinpointing incidents. Drivers see warnings about problems ahead and suggested alternate lanes to use to avoid the congestion.

Installing the structures that hold the signage has been no small job.

“The screens are much larger than what we normally install,” said Schott. “It’s been hard work just because the foundations that hold those signs are pretty substantial.”

That’s not all, said Miske.

“There’s a foundation in the median and on the shoulder for each sign structure — that’s 42 signs total. You have to coordinate a lot of lane closures and full closures of the freeway in order to get it put together. And then you have to work with wiring it and making sure the system is fully integrated.”

A sure bet

As completion grows nearer, Whittick reflects on the progress of the team so far.

“We’re in the entertainment capital of the world here, and we have a lot of people we need to keep happy and coming into their businesses.

“We’ve just done a really good job so far of meeting our schedules, meeting our big dates and keeping traffic impact down. We’ve heard a lot of good things from the traveling public, from the city, and from the state.”

You can bet the Kiewit team will look back on Project NEON with pride and have some best practices to take to the next job.